Perforated aluminum plates offer a perfect combination of durability, aesthetics, and functionality. With multiple alloys, thickness options, and surface finishes, they are ideal for architectural, industrial, and decorative applications.

Choosing our factory ensures:

- High-quality production

- Fast and reliable delivery

- Competitive prices

- Long-term support and customization options

Classification

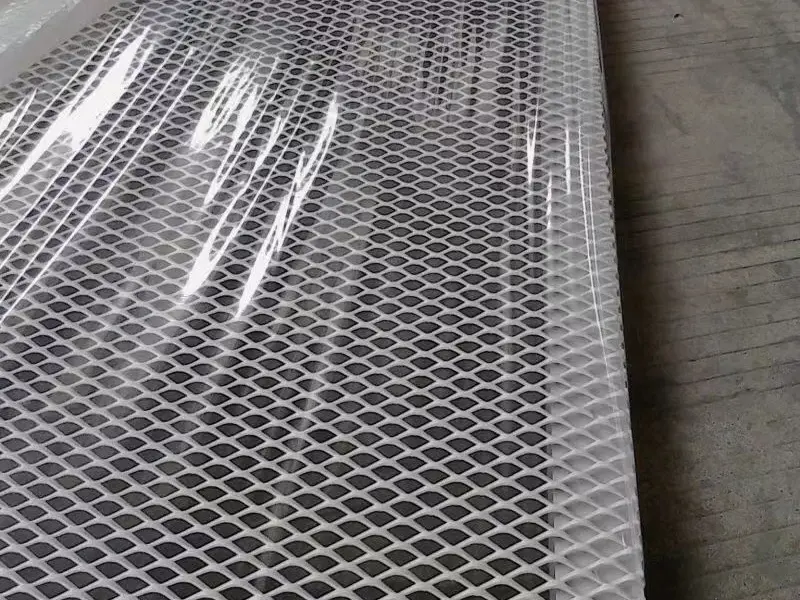

Perforated aluminum plates are classified based on surface pattern, hole shape, and finish.

| Classification | Description |

|---|---|

| By Hole Shape | Round, square, hexagonal, slotted |

| By Open Area | 10% – 70% open area to adjust airflow/light |

| By Surface Finish | Mill finish, brushed, anodized, painted |

| By Alloy | 1050, 3003, 5052, 6061 |

Thickness Options

The thickness of perforated aluminum plates depends on application and load requirements.

| Thickness (mm) | Typical Use |

|---|---|

| 0.5 – 1.0 | Wall panels, decorative interiors |

| 1.2 – 2.0 | Ventilation panels, machine guards |

| 2.5 – 5.0 | Structural perforated panels, heavy-duty use |

Alloy Options

Different aluminum alloys offer strength, corrosion resistance, and workability.

| Alloy | Features | Applications |

|---|---|---|

| 1050 | High purity, soft, easy to punch | Interior decoration, low-load use |

| 3003 | Good corrosion resistance, moderate strength | Outdoor facades, panels |

| 5052 | High corrosion resistance, marine-grade | Coastal environments, industrial |

| 6061 | Strong, excellent machinability | Structural, heavy-duty panels |

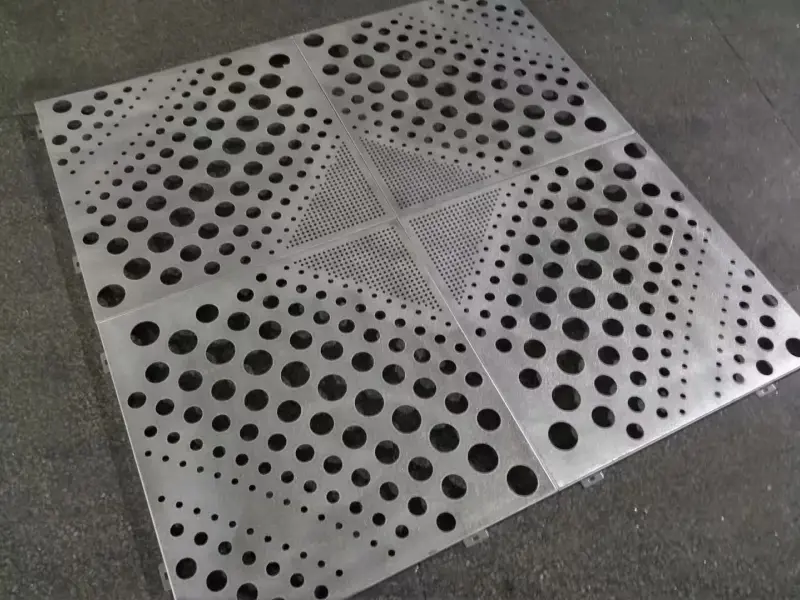

Types of Perforated Aluminum Plates

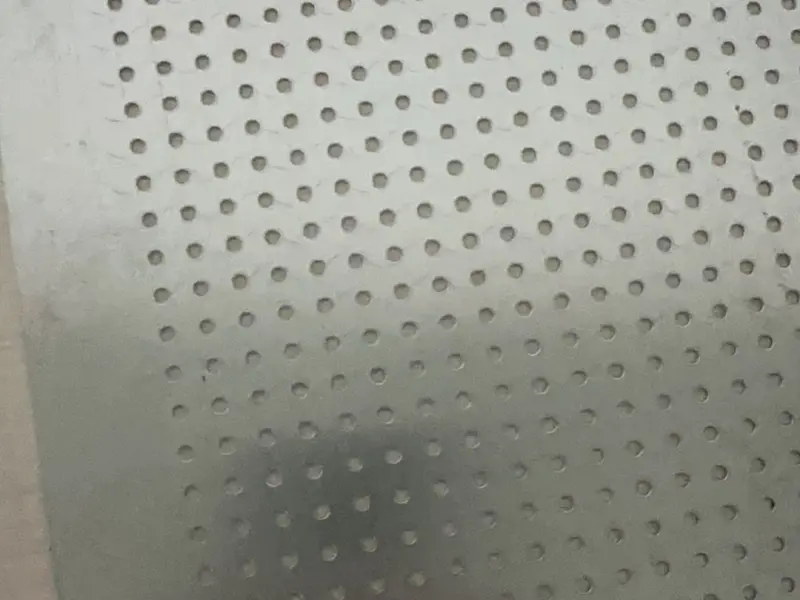

- Flat perforated sheets – standard sheet for walls, ceilings, partitions

- Curved perforated panels – for architectural design and decorative purposes

- Custom perforated patterns – for branding, signage, and interior aesthetics

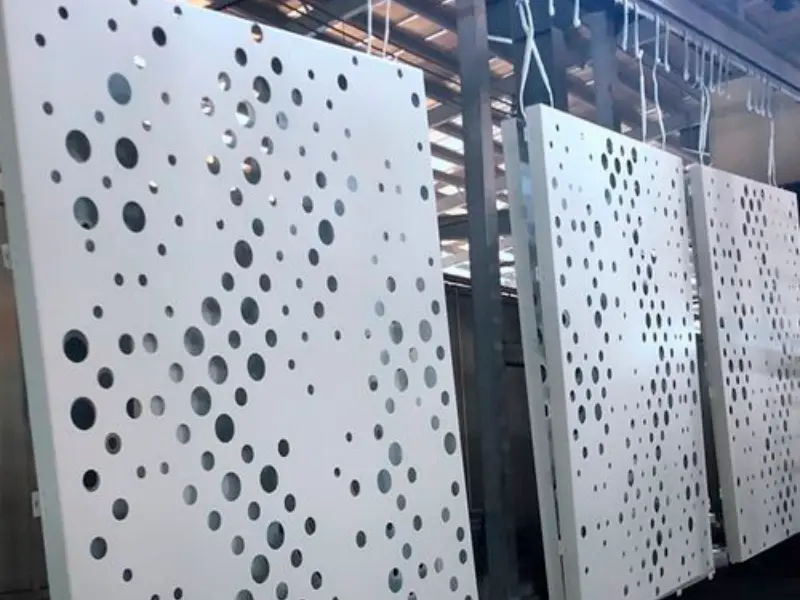

- Powder-coated or anodized sheets – enhanced corrosion protection and color

Factory and Production

Our factory specializes in producing high-quality perforated aluminum plates. Key advantages:

- Modern CNC punching and laser machines for precise patterns

- Strict quality control: thickness, hole size, and finish

- Bulk production capacity: suitable for large projects

- Custom orders: size, pattern, alloy, and surface finish as per client requirements

Perforated Aluminum Sheets In-Stock

We keep various sizes and thicknesses in stock for quick delivery:

| Size (mm) | Thickness (mm) | Alloy | Surface Finish |

|---|---|---|---|

| 1220 x 2440 | 0.5 – 2.0 | 1050, 3003, 5052 | Mill / Brushed / Anodized |

| 1000 x 2000 | 0.8 – 3.0 | 3003, 5052, 6061 | Mill / Painted / Powder-Coated |

| Custom | 0.5 – 5.0 | Alloys | Custom Finish |

Perforated Aluminum Sheet Price

Prices vary based on material, pattern, and quantity:

| Specifications | Price Range (per m²) | Notes |

|---|---|---|

| 0.8mm, round holes | $15 – $25 | Economy grade for indoor use |

| 1.5mm, square holes | $25 – $40 | Standard grade for most applications |

| 3.0mm, custom pattern | $45 – $70 | Premium grade for architectural use |

Factors Affecting Price:

- Material thickness and alloy type

- Hole pattern complexity

- Order quantity

- Surface treatment requirements

Perforated Metal Aluminum Wall Panels & Flat Sheet

Our panels are perfect for architectural applications:

Wall Panel Features:

- Enhanced aesthetic appeal

- Sun shading and privacy control

- Acoustic absorption properties

- Easy maintenance and cleaning

Available Finishes:

- Mill finish (natural aluminum)

- Anodized (various colors)

- Powder coated (custom colors)

- Wood grain or other special effects

Perforated Aluminum Sheet 4×8

The standard 4×8 foot sheet is our most popular size:

Standard 4×8 Sheet Specifications:

- Size: 1220mm x 2440mm (4×8 feet)

- Patterns: Round, square, slotted holes available

- Hole Sizes: 1mm to 20mm diameter

- Materials: 1000, 3000, 5000 series aluminum

Benefits of 4×8 Sheets:

- Easy to handle and transport

- Minimal waste during installation

- Compatible with standard framing systems

- Cost-effective for most projects

Aluminium Sheet Cut To Size – Perforated Metal

We offer custom cutting services to minimize waste:

Cutting Options:

- CNC precision cutting

- Laser cutting for complex shapes

- Straight cutting for simple rectangles

- Deburring and edge finishing

Benefits of Cut-to-Size:

- Reduced material costs

- Faster installation

- Less on-site labor

- Perfect fit for your project

Packaging

Proper packaging ensures safe transportation of perforated aluminum plates:

- Sheets packed with protective film

- Layered with wooden pallets or corner protection

- Seaworthy export packaging for international shipments

- Strapped with steel for heavy-duty coils or large sheets

Applications of Perforated Aluminum Plates

Perforated aluminum plates are highly versatile. Main applications include:

- Architectural & Interior Design: Wall cladding, ceiling panels, room partitions

- Industrial & Machinery: Guards, screens, filtration panels

- HVAC Systems: Ventilation covers, airflow panels

- Acoustic Solutions: Sound-absorbing wall panels

- Decorative & Signage: Custom patterns for branding and aesthetic appeal

What Is a Perforated Aluminum Plate?

A perforated aluminum plate is an aluminum sheet with regular holes or patterns punched or laser-cut into its surface. These sheets combine lightweight strength, corrosion resistance, and decorative appeal, making them ideal for industrial, architectural, and commercial applications.

Common uses include:

- Wall cladding and facades

- Acoustic panels and ventilation covers

- Decorative panels in interiors

- Machine guards and safety screens

- Filtration and separation in industrial applications

FAQ – Frequently Asked Questions

Q1: What is perforated aluminum sheet used for?

A: It is used for ventilation, decoration, protection, and filtration in multiple industries.

Q2: What thickness should I choose for my project?

A:

- Light decorative panels: 0.5–1.0 mm

- Medium-duty ventilation or acoustic panels: 1.2–2.0 mm

- Heavy-duty applications: 2.5–5.0 mm

Q3: Can perforated aluminum be painted or anodized?

A: Yes, powder coating or anodizing enhances corrosion resistance and aesthetic appeal.

Q4: Which alloy is best for outdoor use?

A: Alloys 3003 and 5052 are highly recommended for outdoor applications due to their corrosion resistance.

Q5: Can I get custom hole patterns and sizes?

A: Yes, our factory can produce custom designs, sizes, thicknesses, and finishes based on client requirements.

Why Choose Our Perforated Aluminum Plate?

Reliable delivery with tracking service

20+ years of manufacturing experience

ISO 9001 certified quality management

Competitive pricing with volume discounts

Custom solutions for unique projects