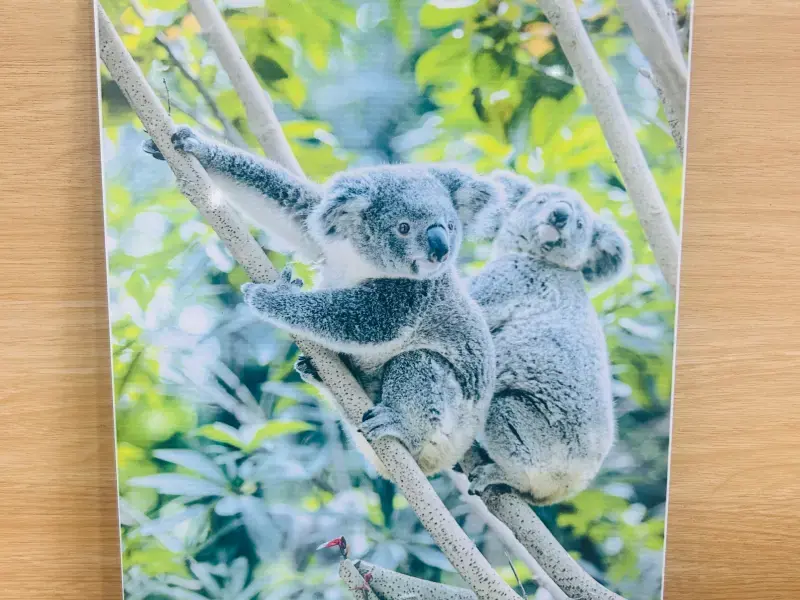

Sublimation printing on metal is a modern way to transfer images, graphics, or logos directly onto coated aluminum sheets or plates. With heat and sublimation ink, the image becomes part of the metal surface. This makes prints bright, durable, and resistant to scratches or fading.

It is widely used for photo decoration, signage, nameplates, and promotional products.

Classification of Sublimation Metal

| Classification | Description |

|---|---|

| Photo Panels | Used for family photos, wedding prints, wall decoration |

| Signage Plates | Door numbers, direction signs, hotel plates |

| Awards & Plaques | Corporate awards, school recognition plates |

| Nameplates | Office, industrial, or machinery tags |

| Decorative Art | Interior design, custom creative projects |

Thickness Options

| Thickness (mm) | Best Use |

|---|---|

| 0.3 mm | Small labels, tags |

| 0.5 mm | Lightweight signs, indoor plates |

| 0.7 mm | Standard plaques, awards |

| 1.0 mm | Photo panels, medium signage |

| 1.5–2.0 mm | Heavy-duty outdoor plates |

Alloy Information

| Alloy | Properties | Application |

|---|---|---|

| 1060 | Pure aluminum, smooth coating | Photo printing, gifts |

| 3003 | Corrosion resistant | Indoor & outdoor signage |

| 5052 | Strong, weather-resistant | Industrial and commercial plates |

Types of Sublimation Metal

| Type | Finish | Features |

|---|---|---|

| Glossy White | High-brightness finish | Sharp and vivid prints |

| Matte White | Non-reflective | Professional look |

| Brushed Silver/Gold | Metallic brushed surface | Modern style |

| Colored Plates | Red, black, blue, etc. | Creative options |

| Custom Shapes | Round, oval, heart | Personalized designs |

Factory Production

Sublimation metal plates are manufactured with precision:

- High-quality aluminum base sheets

- Even sublimation coating lines

- CNC cutting for accurate sizing

- Protective film applied on each sheet

- Bulk production for global supply

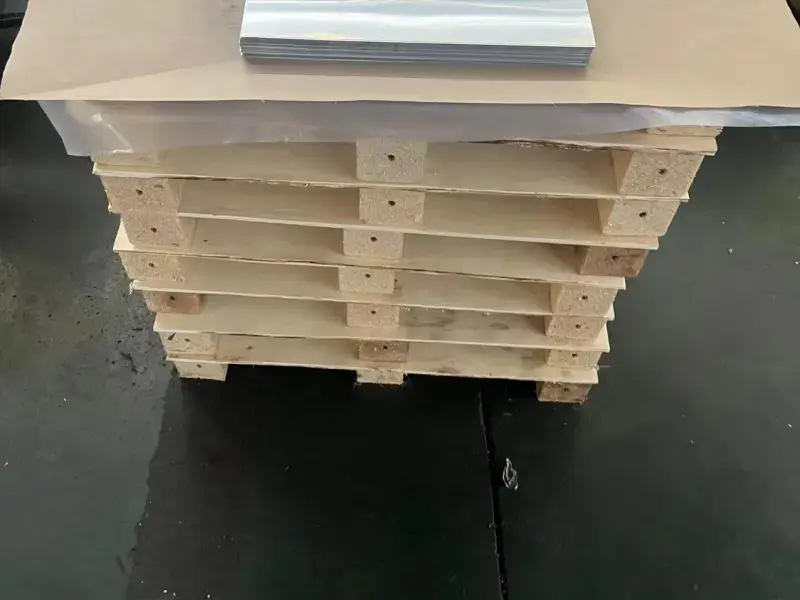

Packaging

To ensure plates reach customers safely:

- Each plate covered with protective film

- Shrink wrap or plastic bag for protection

- Cartons with corner guards

- Wooden pallets for export orders

Applications of Sublimation Printing on Metal

Sublimation on metal is popular in many industries:

- Photography & Art – high-definition photo panels, gallery prints

- Awards & Recognition – school and company awards, plaques

- Corporate Branding – office nameplates, company logos

- Hospitality – hotel door signs, restaurant plates

- Retail & Gifts – personalized items, souvenirs

- Industrial Use – durable labels and tags

What is Sublimation Printing on Metal?

Sublimation printing on metal is a process where heat and pressure are used to transfer dye onto a specially coated metal surface. The ink turns into a gas and bonds with the polymer coating on the metal, creating a permanent, scratch-resistant image. This method is ideal for producing photo prints, signs, and custom artwork.

How Does Sublimation Printing on Metal Work?

The process of sublimation printing on metal involves three main steps:

- Printing: A design is printed in mirror image on sublimation transfer paper using sublimation ink.

- Heating: The printed paper is placed on the metal surface and heated in a heat press.

- Bonding: The ink turns into gas and penetrates the metal’s coating, creating a permanent bond.

This method ensures the image becomes part of the metal itself, rather than sitting on top of it.

FAQ about Sublimation Printing on Metal

Q1: What printer is used for sublimation printing on metal?

A: Any sublimation printer with sublimation inks (Epson, Sawgrass, etc.).

Q2: What is the best temperature and time for sublimation?

A: Usually 180–200°C for 45–60 seconds.

Q3: Can sublimation metal be used outdoors?

A: Yes, especially with 3003 or 5052 alloys.

Q4: What sizes are available?

A: Standard sizes include A4, A3, 30×40 cm, and custom sizes.

Q5: Do plates come with protection?

A: Yes, each plate has a protective film.

Q6: Which thickness is best for photo panels?

A: 0.7 mm to 1.0 mm is the most common choice.