Aluminum veneer sheets are widely used in modern construction, interior decoration, and industrial applications. They provide lightweight durability, corrosion resistance, and an elegant appearance.

Specification

Understanding these classifications is crucial for selecting the ideal aluminum veneer sheet for specific project requirements.

- By Manufacturing Process:

- Solid Aluminum Sheets: These are single-layer aluminum sheets typically formed through cutting, bending, and welding.

- Aluminum Composite Panels (ACP): While distinct, ACPs are sometimes considered within a broader category of aluminum panels. They consist of two thin aluminum sheets bonded to a non-aluminum core. However, this article primarily focuses on solid aluminum veneer sheets.

- By Shape:

- Flat Sheets: The most common form, providing a clean, modern look.

- Curved Sheets: Custom-formed to create organic or artistic architectural elements.

- Perforated Sheets: Feature various hole patterns for aesthetic, light, or ventilation purposes.

- By Surface Finish:

- PVDF Coated Aluminum Veneer Sheets: Offer superior weather resistance and color stability, making them ideal for exterior use.

- Powder Coated Aluminum Veneer Sheets: Provide a wide range of colors and textures, suitable for both interior and exterior applications.

- Anodized Aluminum Veneer Sheets: Create a durable, corrosion-resistant surface with a metallic sheen.

| Classification | Description | Typical Use |

|---|---|---|

| Plain Veneer Sheet | Smooth surface, untreated | Interior walls, ceilings |

| Coated Sheet | PE or PVDF coating for outdoor use | Exterior facades, signage |

| Embossed Sheet | Textured pattern for decoration | Wall panels, decorative facades |

| Perforated Sheet | Holes for ventilation or design | Ceilings, acoustic panels |

Thickness

The thickness of aluminum veneer sheets affects strength, flexibility, and durability.

| Thickness (mm) | Typical Application |

|---|---|

| 1.5 – 2.0 | Interior ceilings, decorative walls |

| 2.0 – 3.0 | Indoor partitions, signage |

| 3.0 – 4.0 | Exterior wall cladding, facades |

| 4.0 – 6.0 | Heavy-duty structural applications |

Alloy Options

Different alloys are used for aluminum veneer sheets based on project needs:

| Alloy | Features | Applications |

|---|---|---|

| 1050 | Pure aluminum, soft, excellent corrosion resistance | Decorative panels, interiors |

| 3003 | Good corrosion resistance, formable, cost-effective | Walls, ceilings, facades |

| 5052 | Strong, marine-grade corrosion resistance | Outdoor, coastal projects |

| 6061 | High strength, durable | Structural, industrial panels |

Types

1. Solid Aluminum Veneer Sheets

Description: Solid aluminum veneer sheets are made of a single layer of high-quality aluminum, providing a smooth and uniform surface.

Characteristics:

- Strong and durable for long-term use

- Lightweight and easy to handle

- Corrosion-resistant and low maintenance

- Can be finished in various colors or textures

Typical Applications:

- Interior walls and ceilings

- Decorative panels

- Architectural facades

2. Composite Aluminum Sheets

Description: Composite aluminum sheets consist of two thin aluminum layers bonded to a core, which can be polyethylene (PE) or honeycomb structure.

Characteristics:

- High rigidity with reduced weight

- Excellent impact resistance

- Fire-retardant options available with special cores

- Can be coated or printed for aesthetic appeal

Typical Applications:

- Building facades and curtain walls

- Signage and advertising panels

- Elevator interiors and partitions

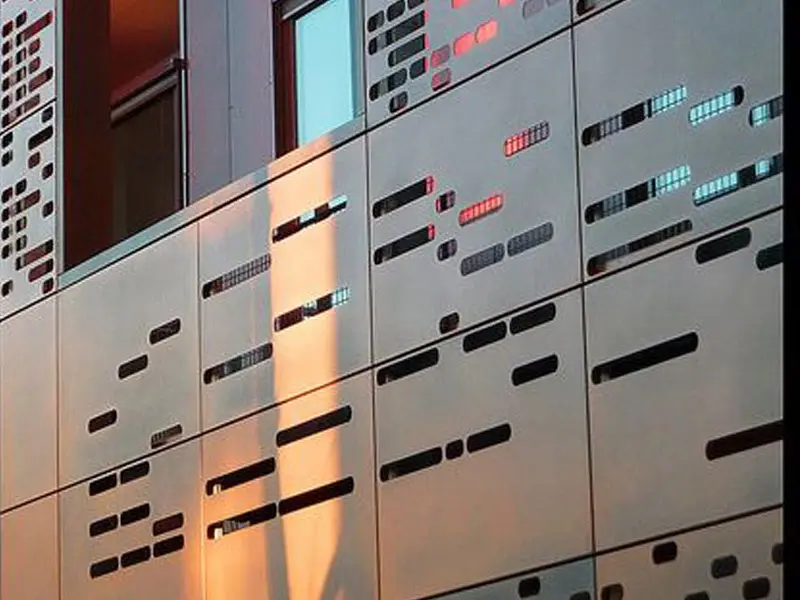

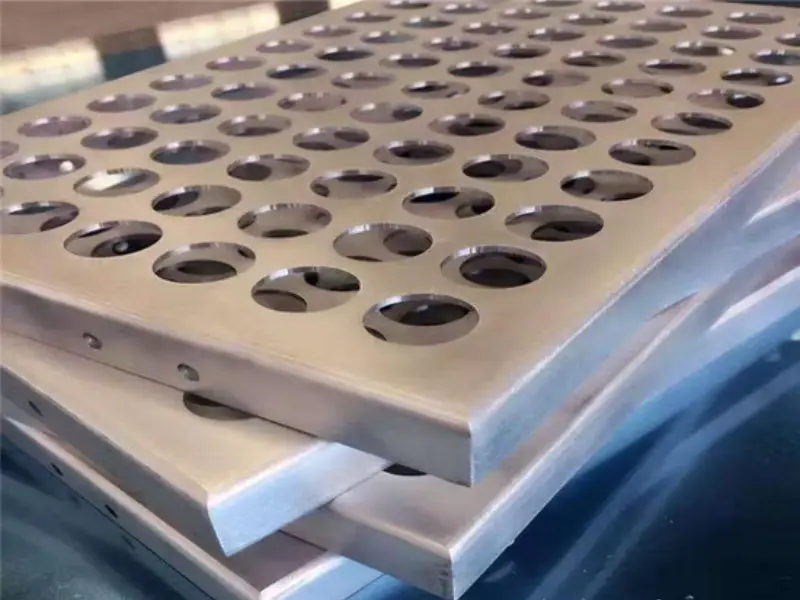

3. Perforated Aluminum Sheets

Description: Perforated aluminum sheets have holes or patterns cut into the surface, providing both decorative and functional properties.

Characteristics:

- Lightweight with enhanced airflow

- Can improve acoustic performance

- Offers modern and stylish designs

- Can be customized with different hole shapes and sizes

Typical Applications:

- Ceilings and wall panels for ventilation

- Acoustic panels in theaters or offices

- Decorative facades or sunscreens

4. Coated Aluminum Sheets

Description: Coated aluminum sheets are finished with protective layers, such as PE, PVDF, or powder coatings, to enhance durability and aesthetics.

Characteristics:

- Excellent resistance to weather, UV rays, and corrosion

- Long-lasting color and gloss retention

- Easy to clean and maintain

- Can be used in both indoor and outdoor applications

Typical Applications:

- Exterior building facades

- Outdoor signage and advertising boards

- Roof panels and decorative architectural elements

Factory and Production Process

Typical production steps:

- Selection of raw aluminum coils

- Cutting and flattening

- Surface treatment (coating, anodizing, embossing)

- Precision shaping and bending

- Quality inspection and packaging

High-quality factories like Worthwill Aluminum ensure customization options for various projects.

Packaging

Proper packaging protects sheets during transportation and storage.

| Packaging Method | Features |

|---|---|

| Wooden Pallet + Plastic | Prevents moisture and scratches |

| Paper Interlayer | Protects surface from abrasion |

| Steel Strapping | Secures sheets during bulk shipment |

| Customized Packaging | According to project or client requirements |

Applications

Aluminum veneer sheets are widely used across industries:

- Architecture: Facades, wall cladding, ceilings

- Interior Design: Decorative walls, partitions, ceilings

- Signage & Advertising: Billboards, shop fronts, display boards

- Industrial: Machinery covers, enclosures, protective panels

- Transportation: Shipbuilding, rail, automotive panels

Frequently Asked Questions (FAQ)

1. Can aluminum veneer sheets be used outdoors?

Yes, especially coated sheets (PVDF or PE) for long-term weather resistance.

2. Are aluminum veneer sheets customizable in size and color?

Yes, they can be cut to size and finished in solid color, wood grain, or stone patterns.

3. What is the recommended thickness for exterior facades?

Typically 3.0 – 4.0 mm for strength and durability.

4. How are aluminum veneer sheets shipped safely?

Sheets are packed with protective film, edge guards, and wooden pallets.

5. Which alloy is best for high-strength applications?

6061 and 5052 alloys are ideal for structural and heavy-duty uses.

More Information Of Aluminum Veneer Sheets

Aluminium veneer sheets provide a combination of durability, light weight, and aesthetic appeal. Understanding their classification, thickness, alloy, types, factory processes, and packaging helps buyers choose the right product.

With proper handling and installation, aluminium veneer sheets are ideal for construction, decoration, signage, and industrial applications, ensuring long-term performance and visual quality.