Aluminum veneer panel is widely used for building facades, wall cladding, ceilings, and decoration because of their durability, lightweight structure, and aesthetic appeal. With various alloys, thicknesses, and surface finishes, aluminum veneer is a reliable solution for modern construction projects.

Classification of Aluminum Veneer Panel

Aluminum veneer panels can be classified by usage, alloy, and coating type:

- By Application: Exterior wall cladding, interior decoration, ceilings, curtain walls.

- By Alloy: 1100, 3003, 5005, 6061.

- By Coating: PVDF coating, powder coating, polyester coating.

- By Surface Finish: Solid color, metallic, stone imitation, wood grain.

Thickness Options

The thickness of aluminum veneer determines strength and performance. Below is a quick guide:

| Thickness | Common Usage | Durability Level |

|---|---|---|

| 2.0 mm | Indoor ceiling, wall panels | Light duty |

| 2.5 mm | Indoor cladding, decorative panels | Medium duty |

| 3.0 mm | Exterior wall cladding, curtain wall | Strong |

| 4.0 mm | Large projects, high-rise buildings | Heavy duty |

Alloy Options

| Alloy | Features | Applications |

|---|---|---|

| 1100 | High corrosion resistance, good surface flatness | Indoor decoration, signage |

| 3003 | Excellent processing, rust resistance | Wall cladding, ceilings |

| 5005 | Strong weather resistance, uniform color coating | Outdoor façade, curtain walls |

| 6061 | High strength, structural applications | Special construction, roofing panels |

Types of Aluminum Veneer Panel

Beyond thickness and alloy, aluminum veneer panels come in various types, each offering unique design possibilities and functions.

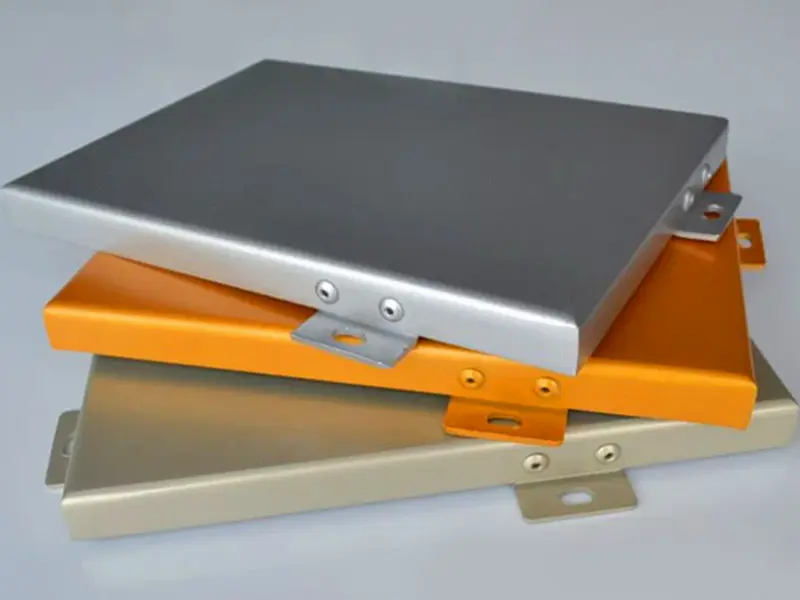

Solid Aluminum Veneer Panels

These are the most basic and widely used aluminum panels. They are flat sheets, usually single-layer, and serve as a versatile solution for general cladding and decorative needs. Their simplicity allows for diverse surface treatments and colors.

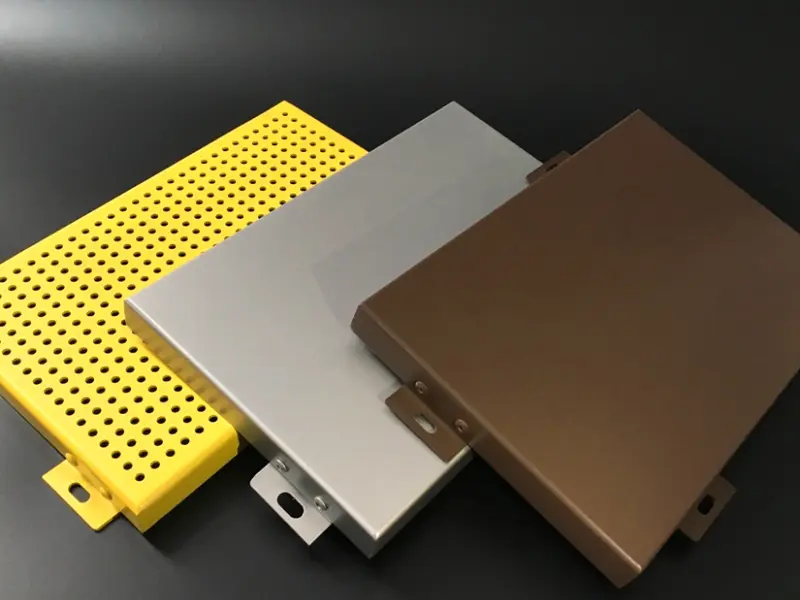

Perforated Aluminum Veneer Panels

Perforated aluminum panels feature patterns of holes. They are chosen for aesthetic effects, light control, ventilation, and even acoustic purposes. The design possibilities are vast, from simple to complex patterns.

| Feature | Description | Common Specifications (Examples) |

|---|---|---|

| Hole Shapes | Round, square, slotted, hexagonal, custom shapes | Round: ø5mm, ø8mm, ø10mm |

| Hole Sizes | Varies from small decorative holes to large functional ones | Square: 10x10mm, 15x15mm |

| Open Area Ratio | The percentage of the panel that is open (holes) | Ratios: 20%, 30%, 45% (influences transparency) |

| Border Width | The unperforated area around the edges of the panel | Often 10-20mm for structural integrity |

Carved/Engraved Aluminum Veneer Panels

These aluminum panels are crafted with intricate designs, patterns, or images. Laser cutting or CNC machining is used to create unique artistic elements, making them ideal for feature walls or decorative screens.

Curved Aluminum Veneer Panels

To achieve specific architectural forms, aluminum veneer panels can be custom-curved. This allows for flowing lines and organic shapes in building facades, creating a distinctive look.

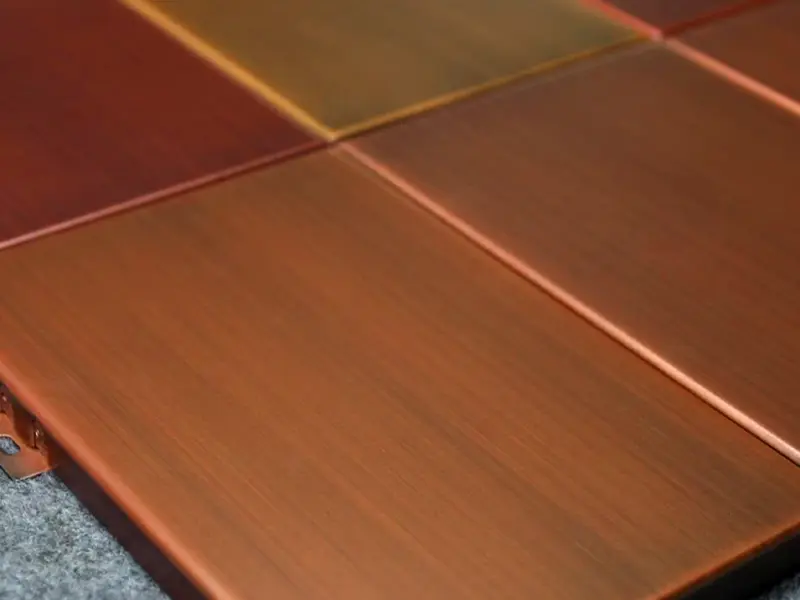

Textured Aluminum Veneer Panels

These panels have special surface textures, such as brushed, embossed, or ripple patterns, adding a tactile and visual dimension to the aluminum panel surface.

Factory Production of Aluminum Veneer Panels

Reputable factories follow strict quality control measures during production. Key steps include:

- Material Selection: High-quality aluminum coils are chosen based on alloy type and intended use.

- Cutting and Shaping: Panels are cut to size using precision machinery.

- Surface Treatment: Panels are cleaned, pre-treated, and coated for enhanced durability.

- Forming: Panels are bent or curved to meet design specifications.

- Quality Inspection: Each panel is checked for defects before packaging.

Packaging & Delivery

To ensure safe transport, aluminum veneer panels are carefully packaged:

- PE protective film on surface.

- Foam layer and edge protection to avoid scratches.

- Strong wooden pallets for export.

- Fast delivery time: usually 15–25 days depending on order size.

Applications of Aluminum Veneer Panel

Aluminum veneer is used across industries:

- ✅ Exterior wall cladding

- ✅ Curtain wall systems

- ✅ Ceilings and column covers

- ✅ Indoor partitions

- ✅ Airport and metro station decoration

- ✅ Shopping mall façades

- ✅ Modern office buildings

Why Choose Aluminum Veneer Panels?

- Lightweight and easy to install

- High corrosion resistance

- Long service life (15–25 years with PVDF coating)

- Multiple color and texture options

- Recyclable and eco-friendly

Frequently Asked Questions (FAQ) about Aluminum Veneer Panel

Q1: What is an aluminum veneer panel used for?

A1: Aluminum veneer panels are mainly used for building facades, wall cladding, ceilings, and interior decoration due to their durability and modern appearance.

Q2: What is the standard thickness of aluminum veneer?

A2: The common thickness ranges from 2.0 mm to 4.0 mm, depending on the project. 2mm–2.5mm is often for interiors, while 3mm–4mm is preferred for exteriors.

Q3: Which alloy is best for aluminum veneer panels?

A3: 3003 and 5005 alloys are popular choices for construction because of their strong corrosion resistance and excellent coating performance.

Q4: How long does PVDF-coated aluminum veneer last?

A4: With PVDF coating, aluminum veneer panels can last 15–25 years without fading under outdoor conditions.

Q5: Can aluminum veneer panels be customized?

A5: Yes. They can be customized in size, shape, thickness, perforation design, and surface finish (solid color, stone, or wood grain).

Q6: What is the difference between aluminum veneer and ACP (aluminum composite panel)?

A6: Aluminum veneer is made of a solid aluminum sheet, while ACP consists of two aluminum layers with a polyethylene core. Veneer offers better durability for façades.

Q7: How are aluminum veneer panels packaged for delivery?

A7: They are packed with PE protective film, foam edge protection, and wooden pallets to avoid scratches and damage during shipping.