Printing on aluminum sublimation sheets is an incredible way to create vibrant, durable, and high-impact custom products. From stunning photo panels to sophisticated signage, the possibilities are vast. However, achieving that “perfect” print – with crisp details, vivid colors, and a flawless finish – requires precision and attention to detail. If you’ve ever dealt with faded colors, blurry images, or pesky imperfections, you know how frustrating it can be.

Fear not! This guide will walk you through 5 essential tips for printing on aluminum sublimation sheets. By mastering these techniques, you’ll consistently produce professional-grade metal prints that truly stand out.

Tip 1: Prepare Your Artwork and Printer Meticulously

The foundation of any great sublimation print begins long before you hit the “print” button. Proper preparation of your artwork and printer settings is paramount.

- High-Resolution Artwork: Always start with high-resolution images (at least 300 DPI) to ensure sharp details on your aluminum sublimation sheet. Low-resolution images will appear pixelated and blurry.

- Color Profile (ICC Profile): Use the correct ICC profile for your sublimation printer and ink set. This ensures accurate color representation, translating what you see on your screen to your final metal print. Without it, colors can look dull or incorrect.

- Mirror Your Image: This is one of the most common mistakes! Sublimation transfers are printed in reverse (mirror image). The heat press process will flip the image, so it appears correctly on your sublimation aluminum blank. Always double-check this setting in your design software or printer driver.

- Printer Settings: Ensure your sublimation printer is set to the highest print quality. Use a “photo” or “best quality” setting to lay down enough ink for a vibrant transfer. Perform nozzle checks regularly to prevent banding or missing lines in your aluminum sublimation prints.

By paying close attention to these initial steps, you set yourself up for success, ensuring your sublimation printing project starts with the best possible image data.

Tip 2: Cleanliness is Crucial: Handle Your Blanks with Care

Even the tiniest speck of dust or a fingerprint can ruin an otherwise perfect printing on aluminum sublimation sheet. The specialized coating is highly receptive, meaning it will pick up everything.

- Remove Protective Film: Aluminum sublimation sheets typically come with a clear plastic protective film on the coated side. This film must be carefully peeled off just before pressing. Forgetting this step will result in a failed transfer and wasted material.

- Cleanliness of the Surface: After removing the film, gently wipe the surface of your sublimation aluminum blank with a microfiber cloth or a lint-free wipe. Some users even use a little rubbing alcohol or a specialized sublimation cleaner to ensure there are no oils or residues.

- Avoid Touching the Coating: Once the film is removed and the surface is cleaned, avoid touching the coated area with your bare hands. Fingerprints contain oils that can prevent ink from transferring properly, leaving unsightly marks on your custom metal print.

- Clean Environment: Work in a clean, dust-free area. Even airborne dust can settle on your blank or transfer paper, leading to imperfections.

This simple tip can make the difference between a pristine sublimation print and one marred by tiny flaws.

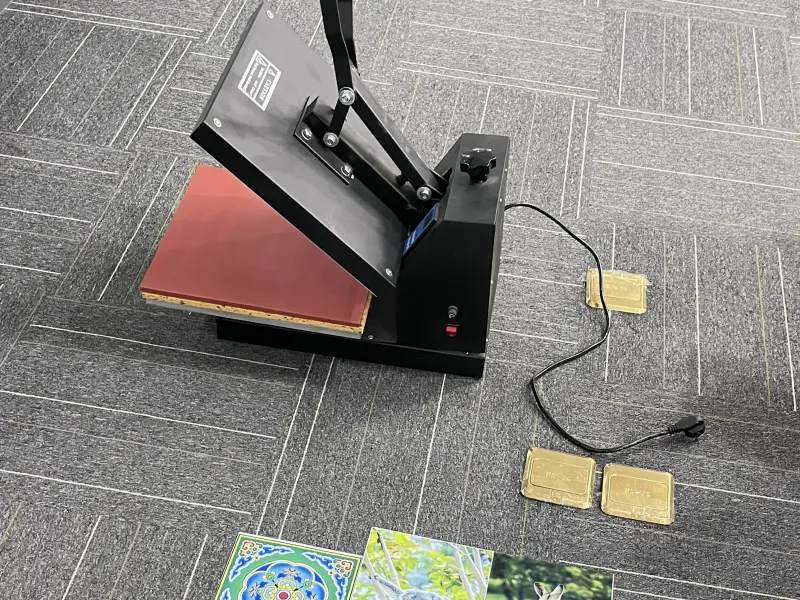

Tip 3: Master Your Heat Press Settings (Time, Temperature, Pressure)

The heat press is the heart of the sublimation printing process. Getting the time, temperature, and pressure exactly right is critical for a perfect transfer to your aluminum sublimation sheet. These settings can vary slightly depending on your specific heat press model, ink, paper, and the sublimation blank itself.

- Temperature: Most aluminum sublimation sheets require temperatures between 380°F (193°C) and 400°F (204°C). Too low, and the colors will be faded; too high, and colors can “burn” or become muddy.

- Time: The typical dwell time for metal prints ranges from 45 to 90 seconds. Shorter times can result in incomplete transfers, while longer times can cause image burning or ghosting.

- Pressure: Firm, even pressure is essential. Too little pressure can lead to uneven transfers, light spots, or ghosting. Too much pressure can sometimes warp thinner aluminum sheets or affect the coating.

- Testing is Key: If you’re using a new type of aluminum sublimation blank or a new heat press, always perform test prints on small scraps. Adjust settings incrementally until you achieve the desired vibrancy and clarity.

Precise heat press settings are non-negotiable for producing professional-quality sublimation aluminum prints.

Tip 4: Secure Your Transfer Paper Effectively

Even with perfect artwork and heat press settings, a shifting transfer paper can ruin your printing on aluminum sublimation sheet with “ghosting” – a blurry, duplicated image effect.

- Heat-Resistant Tape: Always use high-quality heat-resistant tape to secure your printed sublimation paper to the aluminum sublimation blank. Apply tape to at least two (preferably four) sides of the paper, ensuring it’s taut against the blank.

- Minimize Movement: Once taped, try not to move the blank and paper assembly more than necessary before placing it in the heat press. Any slight shift can cause ghosting.

- Butcher Paper/Blowout Paper: Place a sheet of clean butcher paper or non-stick parchment paper between the heat platen and your sublimation assembly. Also, place one underneath. This serves two purposes:

- It protects your heat press from stray ink that might bleed through the sublimation paper.

- It helps absorb any moisture or excess ink, further preventing ghosting and ensuring a clean transfer to the sublimation aluminum sheet.

- Thermal Pad (Optional): Some users find a thin thermal pad (silicone or felt) on the bottom platen can help distribute heat and pressure more evenly, leading to better overall metal prints.

Properly securing your transfer ensures that the image is transferred precisely where it should be, without unwanted blurs.

Tip 5: Proper Cooling and Handling Post-Press

The work isn’t over once the timer goes off. How you handle your aluminum sublimation sheet immediately after pressing is crucial for the final quality.

- “Hot Peel” vs. “Cool Peel”: For aluminum sublimation sheets, a “hot peel” is almost always recommended. This means removing the sublimation paper immediately after lifting the heat press platen. This helps prevent the ink from re-gassing and causing ghosting as the blank cools.

- Cooling Down: After peeling, allow the sublimation blank to cool completely before handling it excessively or attempting any further processing (like framing or mounting). The coating is still somewhat pliable when hot and can be easily scratched or damaged.

- Flat Cooling: Place the hot metal print on a flat, heat-resistant surface to cool. Avoid placing it on uneven surfaces or propping it up, as this can sometimes lead to warping, especially with thinner sheets.

- Inspect and Admire: Once cooled, you can fully inspect your perfect custom metal print! Look for any imperfections, check color accuracy, and enjoy the sharp, vibrant results.

By following these post-press handling tips, you protect your hard work and ensure the longevity and beauty of your sublimation aluminum sheet creation.

Why Perfect Printing Matters: Applications of High-Quality Aluminum Sublimation

Achieving perfect prints on aluminum sublimation sheets isn’t just about technical skill; it’s about the impact and longevity of your creations. High-quality metal prints offer numerous advantages and applications:

- Professional Photography Displays: Showcasing stunning photos with vibrant colors and exceptional detail.

- Fine Art Reproductions: Creating durable and museum-quality copies of original artworks.

- Corporate Awards and Plaques: Crafting prestigious and lasting recognition pieces.

- High-End Interior Decor: Producing modern and sleek wall art for homes and offices.

- Retail Signage and POP Displays: Manufacturing eye-catching and durable signs that enhance brand image.

- Personalized Gifts: Offering unique, cherished items like photo gifts, keychains, and ornaments that last.

- Outdoor Signage (with appropriate coating): Creating weather-resistant and fade-proof informational or decorative signs.

Each application benefits immensely from the clarity, vibrancy, and durability that only perfect sublimation printing on aluminum can provide.

Common Types and Specifications of Aluminum Sublimation Sheets

Understanding the varieties of aluminum sublimation sheets can further help you select the right blank for your perfect print.

| Feature | Description | Common Specifications | Notes on Quality & Printing |

|---|---|---|---|

| Material | High-grade aluminum alloy, specially coated for sublimation. | Alloys: 5005, 6061 (ensure flatness and coating adhesion) | A good alloy is essential for a flat, even print surface. |

| Coating Type | The polymer layer that accepts the ink. | White Gloss: Most common, vivid colors. White Matte: Reduced glare. Brushed Metal: Unique metallic sheen. | Affects final look and feel. Gloss is generally most vibrant. |

| Thickness | The gauge of the aluminum, impacting rigidity and feel. | 0.5 mm (0.02 in): Lightweight, flexible. | Can warp if not cooled properly. |

| 0.7 mm (0.028 in): Standard, good balance of durability. | Versatile for many applications. | ||

| 1.1 mm (0.043 in): Heavy-duty, premium feel, maximum rigidity. | Less prone to warping, ideal for larger metal prints. | ||

| Sizes | Available dimensions for various projects. | Standard photo sizes (e.g., 4″x6″, 8″x10″, 11″x14″), large panels (e.g., 20″x30″, 24″x36″), custom cuts. | Choose size to match artwork; larger prints require larger heat presses. |

| Protective Film | Clear plastic film on the coated surface. | Always present on quality blanks. | Must be removed before pressing for perfect results. |

| Packaging | How sheets are protected during transit. | Interleaving paper/foam, sturdy cartons, edge protectors. | Critical to prevent scratches and damage to sublimation blanks. |

Why Use Aluminum Sublimation Sheets?

Aluminum sublimation sheets are specially coated panels designed for high-definition printing. They are widely used because they are:

- Scratch-resistant and durable

- Lightweight yet strong

- Available in different finishes (glossy, matte, pearl, brushed, white, silver)

- Perfect for indoor and outdoor use

Applications include:

Industrial tags and labels

Photo panels

Wall art and décor

Signage and nameplates

Personalized gifts