Wood Aluminum

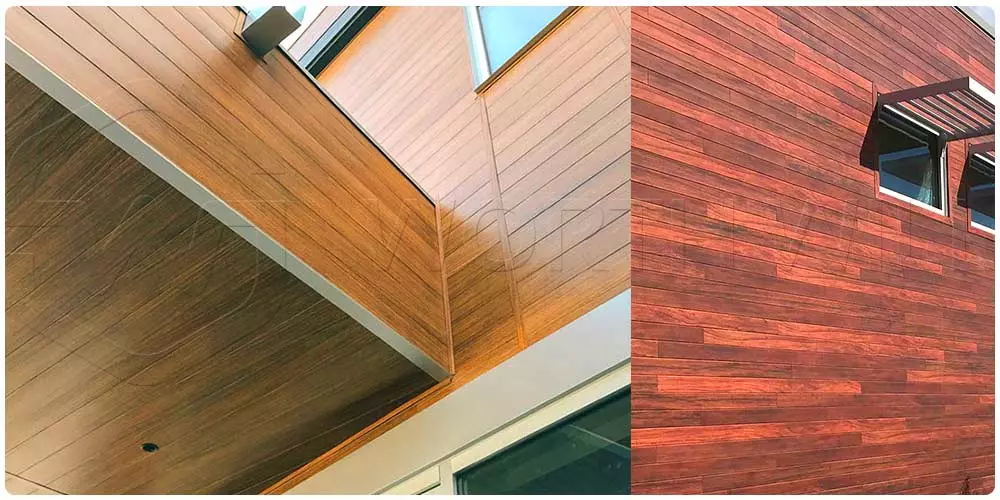

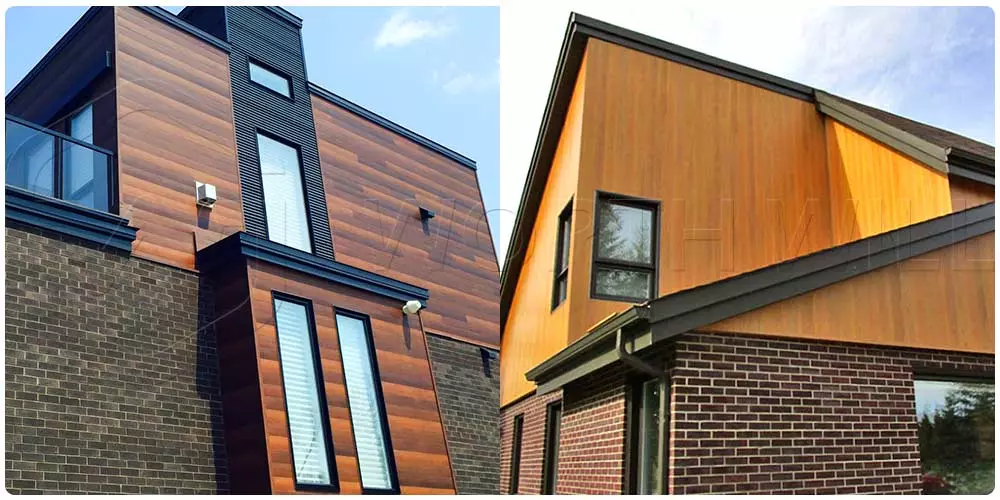

Wood aluminum belongs to color coated aluminum. The patterns on the surface of wood grain aluminum sheet are imitation wood grain. Imitation wooden aluminum sheet, with various colors and patterns, are enough emulation wood feeling and fresh natural beauty.

| Product: | Wooden Aluminum |

| Coating thickness | Above 25 microns |

| Alloy : | 1060, 1100, 3003, 3004, etc. |

| Temper: | H24, etc. |

| Width: | 30-1350mm (or as per requirments) |

| Delivery: | Within 30 days |

| MOQ: | 2-4 tons |

Advantages

- Excellent decoration performance

- Good weather resistance

- Excellent color and

- Gloss retention and

- Durability

- Good consistency

- Uniform film thickness

Application

Wood grain aluminum sheet is widely used for interior decoration, ceiling plate, wallboard, roofing, aluminum square, furniture, all kinds of exterior and interior wall decoration.

Specification

Item: Imitation wooden aluminum sheet/coil

Alloy: 1060/1100/3003/3004 or as per customer’s requests

Temper: H24 etc.

Coating thickness: Above 25 microns

Base aluminum size: 0.25-1.35mm x 30-1350mm x C

Capacity/month: 500 Tons

Imitation wood grain aluminum sheet

The imitation wood grain aluminum sheet has light weight, exquisite, rich wood grain pattern, strong hardness, durable, fireproof, moisture-proof, high plasticity, simple installation and saving construction costs, which can meet the needs of different architectural decoration.

The price of wood aluminum sheet

The sheet and coil have the same price. The price of wood aluminum sheet is depend on the price of aluminum ingot and paint. We use the best aluminum ingot as material, and the famous paint in our country. We will give you a competitive price on the premise of ensuring quality. If you order in bulk, we also can provide you a discount.

With roll coating

Roll coating uses a rotating roller as the carrier of the coating. Roll coating is suitable for flat coating, widely used for coating metal plate, plywood, cloth and paper, especially for metal coil coating. It can replace the brush coating method, which will improve the coating efficiency.

The advantages of roll coating

- High-speed automatic operation, fast coating speed, high production efficiency, and up to 244m/min.

- No paint mist and splashing. The coating efficiency is close to 100%.

- Roll coating is suitable for both low and high viscosity coatings, and the process can control the thickness of the paint film more accurately and uniform.

- It can paint the front and back at the same time.

Coated color aluminium sheet coating

There are two types of coated aluminum sheet include PE and PVDF.

PE: The polyester coating formed by repeatedly baking the surface of the aluminum plate, then can form a continuous solid film. That is firmly attached and has protective and decorative properties.

PVDF: Fluorocarbon coatings mainly refer to coatings of vinylidene fluoride homopolymer, or copolymers of vinylidene fluoride, and other small amounts of fluorine-containing vinyl monomers.

Same: 1. Both plain topcoats and metallic paints are available

- Both double-coated

Distinguish: 1. PE is generally used indoors. The other is generally used outdoors.

- PE has a warranty of 15-20 years. PVDF has a 10-year warranty.

- PE only has single coating and double coating. PVDF includes double coating and triple coating.

- PE is mostly used for coil. PVDF is mostly used for sheet.

The coating process line

- Put the plain coils in the decoiling machine and let it trough the Material storage tower. (To prevent turn off the whole processing line when we change new coil)

- Pre-processing. Firstly through the alkaline water tank to degrease the coil, secondly use the tap water to clean, then the acid to neutralize the remnant alkali, at last completely clean with pure water.

- (The temperature is 210-230 degree Celsius)

- Add the chromium to passivate the coil and enhance the adhesive strength.

- Coat the bottom of the coils with clear varnish or white and gray paint.

- Drying.

- Use air cooling system or water cooling system to cool them down.

- Drying again. (Water cooling system)

- According to customers’ requirement to make second coating.

- Drying

- Cooling.

- Covering the surface of coils with plastic film.

- Packaging with inner paper tube about 15-20mm in thickness.

- Sending them to the storage.

Wood grain aluminum sheet factory

We have our own factory, and it’s located in Henan, China. Our factory has advanced and complete machine, such as slitting machine, embossing machine, brushing machine and cutting machine. We use the best roller coating process. The production capacity of Worthwill is 1-8 series and aluminum sheet, aluminum plate, aluminum circles/disk, aluminum strip, aluminum coil, aluminum foil, aluminum tread plate and so on.

Wood grain aluminum surface manufacturer and exporter

While we also have mature business team and we serviced for domestic and foreign customers. We have many years of export experience and Worthwill is dedicated to provide you quality products with competitive price and quick after-sales services. We strive to develop as an excellent company of scale, industrialization, professionalization, internationalization with prime brand.

Our service

- Provide free samples for your reference

- Reply to your message within 12 hours

- Professionals answer your questions

- Passionate business team

- Perfect after-sales service system

FAQ

Why choose us?

- Advanced equipment: Our factory uses the latest production equipment, and regularly checks the condition of the machine, in order to produce the best products.

- Own factory, reasonable price: We adopt the best aluminum material, and our own factory that we can provide you the factory price. On the premise of ensuring quality, we will give the competitive price.

- Wealth experience: Our factory is located in the industrial Our company has been established many years. We have excellent and experienced business team and skilled worker.

- Customized products: We have many models for you to choose.You can also send our your sample to us, we will produce the products which satisfy your requirement.

- Exporting dozens of countries: Nowadays, aluminum productsdevelop brightly in the national market. Our products has exported to many countries as South Africa, Mexico, Bolivia etc.

- Offering free sample: To ensure our products’ quality and satisfy customers’ requirement, our company provides free sample for your reference.

Why people choose aluminum furniture?

After aluminum furniture is processed, the appearance and effect are same as wooden furniture, so what is the difference between aluminum furniture and traditional wooden furniture and why people choose aluminum furniture?

Aluminum furniture vs wooden furniture:

- Aluminum is a natural metal does not contain formaldehyde.But wooden furniture, no matter how good the material is, can’t avoid formaldehyde.

- Aluminum furniturewith many advantages like fireproof, waterproof, anti-corrosion, moth-proof and mildew-proof.Compared with wooden furniture, the comparison is really incomparable.

- Aluminum furniture is recyclable and contains a certain appreciation space. Although wooden furniture can also be recycled, the price difference between the two is absolutely huge.