In various industries, from manufacturing to construction, protecting surfaces during production, transportation, and installation is crucial. White protective film is an essential material that offers temporary protection for surfaces, ensuring they remain clean, scratch-free, and in optimal condition. If your business involves handling delicate materials or finished products, investing in white protective film can save you time, money, and effort by preventing damage during these critical phases.

Key Benefits

1. Surface Protection

The primary purpose of white protective film is to safeguard surfaces from scratches, scuffs, dust, and contaminants. Whether you’re working with metals, plastics, glass, or other materials, this film ensures that the surface remains intact and blemish-free throughout production, storage, or transportation.

2. Cost-Effective Damage Prevention

Repairing or replacing damaged surfaces can be costly and time-consuming. White protective film offers a cost-effective solution by preventing damage before it occurs. By minimizing the risk of surface defects, your business can save on repair costs and avoid delays in production or delivery.

3. Easy Application and Removal

White protective film is designed for easy application and removal. It adheres securely to surfaces, providing reliable protection. Yet it can be removed without leaving sticky residue or damaging the material underneath. This ease of use makes it a practical choice for a wide range of applications.

4. Versatility Across Industries

White protective film has uses in many industries, including manufacturing, construction, automotive, electronics, and more. Its versatility makes it suitable for protecting everything from metal sheets and glass panels to finished products like appliances, furniture, and fixtures.

5. Enhanced Aesthetics and Cleanliness

The white color of the film provides a clean, professional appearance while protecting the surface. It can also help keep products looking pristine by preventing dirt and dust from accumulating during handling or transportation. This is especially important for products that will be delivered to customers or installed in visible areas.

Common Applications

1. Metal Fabrication and Manufacturing

In the metal fabrication industry, white protective film has uses to protect metal sheets, coils, and finished parts from scratches, fingerprints, and contaminants during production and handling. The film helps ensure that the final product is delivered to customers in perfect condition.

2. Construction and Renovation Projects

During construction and renovation projects, white protective film has application to surfaces. Such as windows, doors, countertops, and floors to prevent damage from tools, debris, and foot traffic. It offers temporary protection that can be easily removed once the work is complete.

3. Appliance and Electronics Protection

Manufacturers of appliances and electronics use white protective film to safeguard surfaces like stainless steel, glass, and plastic during assembly, packaging, and transportation. This helps prevent scratches and ensures that products arrive at their destination looking brand new.

4. Automotive Industry

In the automotive industry, protective film is to protect painted surfaces, glass, and interior components during manufacturing and shipping. It helps maintain the quality and appearance of vehicles until they are ready for sale or delivery.

5. Furniture and Fixtures

For businesses involved in the production or installation of furniture and fixtures, protective film can protect surfaces from damage during handling and installation. This ensures that products remain in perfect condition and ready for use in homes or commercial spaces.

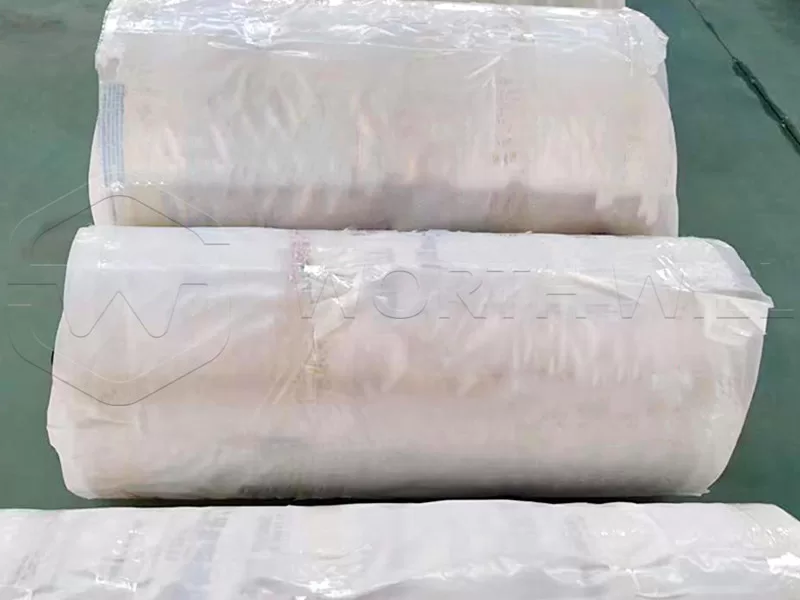

What is White Protective Film?

White protective film is a type of adhesive film made from durable polyethylene or similar materials. It is to surfaces to provide a temporary protective layer that shields against scratches, dirt, moisture, and other potential damage. The film is typically white in color. It offers a clean appearance that can easily be removed without leaving residue once the protection is no longer needed.

Considerations When Choosing White Protective Film

1. Surface Compatibility

Not all protective films are suitable for every surface. When choosing protective film for your business, consider the materials you need to protect. Ensure that the film is compatible with the surface to prevent issues such as adhesion problems or difficulty in removal.

2. Adhesion Strength

Different applications may require different levels of adhesion. For example, a stronger adhesive may be necessary for rough surfaces, while a lighter adhesive may be preferable for delicate surfaces. Select a film with the right adhesion strength for your specific needs.

3. Thickness and Durability

The thickness of the film can affect its durability and protective capabilities. Thicker films offer more robust protection but may be more challenging to apply and remove. Thinner films are easier to handle but may provide less resistance to heavy wear and tear. Choose the right balance of thickness and durability for your application.

4. Removal and Residue

One of the key benefits of protective film is its ability to be removed without leaving residue. Be sure to choose a high-quality film that ensures clean removal, especially if the protected surfaces are visible or critical to the final product’s appearance.

Conclusion

White protection film is an essential tool for businesses that need to protect surfaces during production, transportation, and installation. Its ability to prevent damage, reduce costs, and maintain the quality of your products makes it a valuable investment for any industry. By choosing the right film for your specific needs, you can ensure that your materials and products remain in pristine condition throughout every stage of the process.

If you’re considering adding white protective films to your business operations, contact us today to explore our range of options. Our team can help you find the perfect solution to meet your protection needs, ensuring your surfaces stay safe and your products stay top-notch.