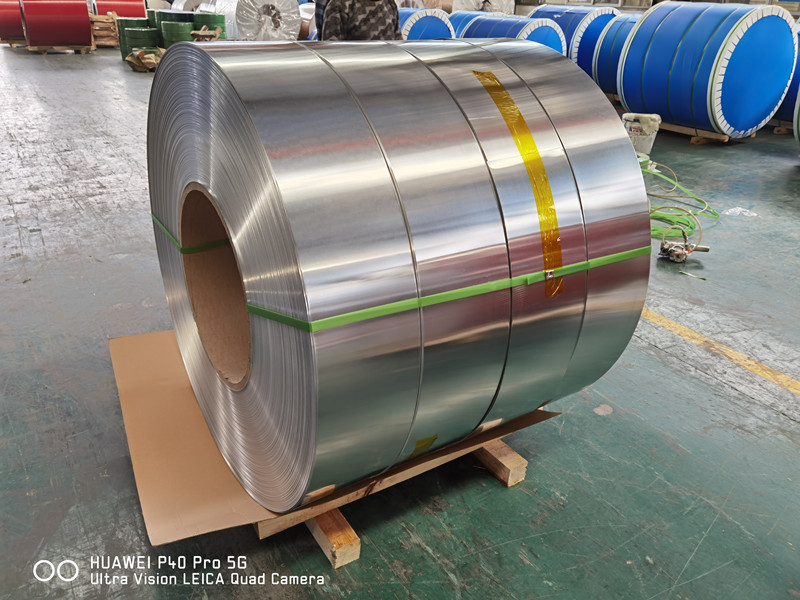

Mill finish aluminum coils are a versatile material used in a wide range of industries and applications. Their natural, uncoated surface makes them suitable for various operations, from manufacturing and construction to transportation and electronics. Understanding the different types of mill finish aluminum coils can help you select the right material for your specific needs. Here’s a look at the types of mill finish aluminum coils and their applications.

1. 1000 Series Mill Finish Aluminum Coil

- Pure Aluminum Content: The 1000 series aluminum coils are made of at least 99% pure aluminum. This series includes popular alloys like 1050, 1060, and 1100, known for their excellent corrosion resistance and good formability.

- Applications: Due to their high purity, 1000 series coils are often used in chemical equipment, heat exchangers, and food processing industries where corrosion resistance is essential. They are also used in signage and reflective surfaces.

2. 3000 Series Mill Finish Aluminum Coil

- Manganese Alloyed: The 3000 series contains manganese as the primary alloying element, with alloys like 3003 and 3105 being common. These coils offer a good balance of strength and corrosion resistance while maintaining excellent formability.

- Applications: 3000 series coils are commonly used in the production of roofing materials, siding, and HVAC systems. They are also used in the manufacturing of beverage cans and cooking utensils.

3. 5000 Series Mill Finish Aluminum Coil

- Magnesium Alloyed: The 5000 series, such as 5052 and 5083, is alloyed with magnesium, providing higher strength and better corrosion resistance, particularly in marine environments. These coils also offer good weldability and moderate formability.

- Applications: 5000 series aluminum coils are ideal for marine applications, fuel tanks, and pressure vessels. They are also used in transportation, including automotive and aerospace industries, where strength and corrosion resistance are crucial.

4. 6000 Series Mill Finish Aluminum Coil

- Silicon and Magnesium Alloyed: The 6000 series, including alloys like 6061 and 6082, is known for its versatility. These coils combine good mechanical properties with excellent corrosion resistance and workability.

- Applications: 6000 series coils are widely used in structural applications, including building frames, bridges, and pipelines. They are also used in the manufacturing of machinery, automotive parts, and heavy-duty structures.

5. 8000 Series Mill Finish Aluminum Coil

- Specialized Alloys: The 8000 series includes specialized alloys that are not as commonly used as other series. One example is 8011, which is primarily used in packaging, particularly for aluminum foil production.

- Applications: 8000 series coils are used in specific applications where unique properties are required, such as packaging, electrical applications, and certain industrial uses.

6. Custom Alloy Mill Finish Aluminum Coil

- Tailored Solutions: In addition to the standard series, custom alloys can be developed to meet specific operational needs. These custom alloys may offer enhanced performance in terms of strength, corrosion resistance, or thermal conductivity.

- Applications: Custom alloy coils are used in specialized industries where standard alloys may not meet the required specifications. This includes advanced manufacturing, aerospace, and high-performance automotive applications.

7. Surface Finishes and Treatments

- Uncoated Surface: Mill finish aluminum coils have an uncoated surface, which can be left as-is or further treated depending on the application. The natural finish is often preferred for its raw, industrial look or as a base for further processing.

- Anodizing and Painting: While mill finish is the starting point, these coils can be anodized, painted, or coated for enhanced aesthetics and protection, depending on the specific requirements of the operation.

Conclusion

Mill finish aluminum coils offer a range of options suitable for different operations across various industries. From the high purity of the 1000 series to the strength of the 5000 and 6000 series, each type of mill finish aluminum coil provides unique benefits that cater to specific applications. Understanding the differences in alloy composition and properties is crucial for selecting the right material for your project, ensuring optimal performance and cost-effectiveness. Whether you’re in construction, manufacturing, or transportation, there’s a mill finish aluminum coil that can meet your operational needs.