Unlock a world of vibrant color and lasting quality with sublimation aluminum sheet. These specially coated aluminum blanks are revolutionizing how we create high-definition images, artwork, and signage. If you’re looking for a durable, eye-catching, and versatile medium for your designs, sublimation aluminum offers an unparalleled solution.

Specifications

Our aluminum sublimation sheets come in various finishes and thicknesses to meet your printing needs:

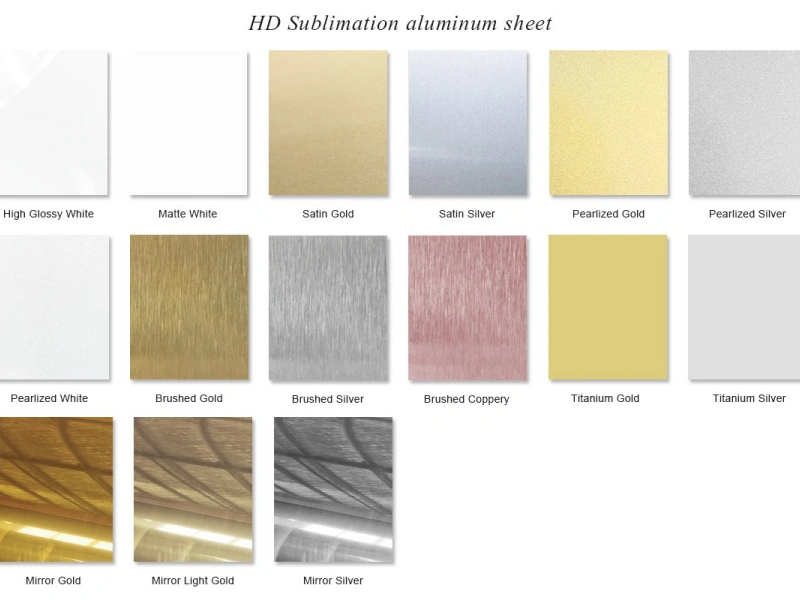

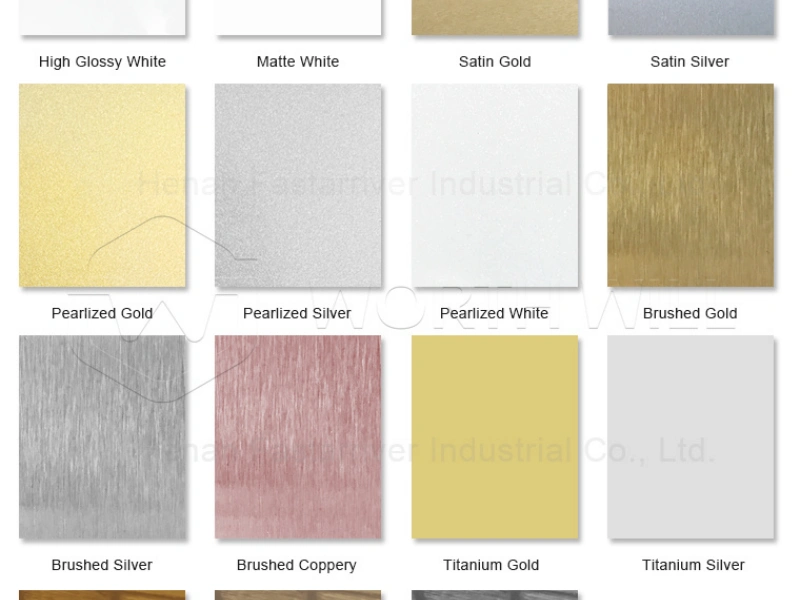

- Available Finishes:

- White Gloss

- White Matte

- Brushed Silver

- Clear Gloss

- Gold Finish (on request)

- Common Thickness Options:

- 0.3mm, 0.5mm, 0.7mm, 1.0mm

- Custom thickness available

- Standard Sheet Sizes:

- 4″x8″, 8″x10″, A4, A3

- Full sheets: 600mm x 1200mm, 1220mm x 2440mm

- Custom sizes available

- Alloy: 1050 / 1060 / 3003 (soft temper, easy for cutting and pressing)

Can You Sublimate on Aluminum Sheets?

✅ Yes! Our sheets feature a polyester coating that bonds with sublimation inks at 400°F (204°C) for 45-60 seconds.

Pro Tip: Always use high-quality sublimation ink and Teflon sheet protection.

Sublimation Temperature for Aluminum

| Step | Temperature | Time |

|---|---|---|

| Preheat | 350°F (177°C) | 30 sec |

| Pressing | 400°F (204°C) | 45-60 sec |

| Cool Down | Room temp | 2 min |

⚠️ Warning: Exceeding 425°F (218°C) may damage the coating.

Key Specifications of Sublimation Aluminum Sheets

Understanding the properties of sublimation aluminum sheets helps in selecting the right product for your project.

Classification

Sublimation aluminum sheets are typically classified by their intended use and surface finish. Common classifications include:

- Standard Gloss: The most popular choice, offering brilliant colors and a reflective surface.

- Matte Finish: Provides a non-glare look, ideal for reducing reflections.

- Brushed Finish: Features a textured, brushed metallic appearance through which the image subtly shines.

- White Base: Ensures true color representation.

- Clear/Silver Base: Allows the natural aluminum color to show through in unprinted areas, creating a metallic effect.

Thickness

The thickness of sublimation aluminum sheets varies, with common options designed for different applications:

- 0.5mm (0.020 inches): Lightweight, often used for smaller decorative items, jewelry, or thin signage.

- 0.8mm (0.032 inches): A popular all-around thickness, offering good rigidity for photo panels, awards, and general signage.

- 1.0mm (0.040 inches) and thicker: Used for more robust applications, large signs, or where greater rigidity is required.

The specific thickness you choose will depend on the final product’s size, rigidity requirements, and desired feel.

Specialized Coatings and Finishes

The magic of sublimation aluminum lies in its specialized coating. This polyester layer is engineered to bond permanently with sublimation dyes. Beyond this functional coating, sublimation aluminum sheets are available with various aesthetic finishes, such as:

- Gloss White: A bright, reflective white surface that makes colors pop.

- Matte White: A non-reflective white, offering a softer, more artistic look.

- Gloss Clear (Silver): A clear coating over the raw aluminum, allowing the metallic sheen to be part of the image.

- Brushed Silver: A clear coating over brushed aluminum, giving a unique texture and metallic depth, perfect for sublimation blank brushed silver aluminum sheets.

- Gloss Gold/Brushed Gold: Similar to silver options but with a gold tone.

Alloy

The aluminum alloy used for sublimation sheets is typically chosen for its flatness, smooth surface, and compatibility with the coating process. Common alloys include 1100, 3003, or 5052 series aluminum. These alloys provide a stable base for the specialized coating and ensure the finished product’s durability.

Aluminum Sublimation Sheet Prices

Sample Price Table (2024 Market Rates):

| Size | Qty 50 | Qty 500 |

|---|---|---|

| 4″x8″ | $2.99/ea | $1.89/ea |

| 8″x12″ | $4.50/ea | $3.25/ea |

| 12″x18″ | $7.80/ea | $5.40/ea |

💡 *Bulk discounts available for 1,000+ units*

Can You Sublimate on Aluminum Sheets? Yes, Absolutely!

Yes, you can absolutely sublimate on aluminum sheets! In fact, aluminum sublimation is one of the most popular and effective ways to create stunning, vibrant, and incredibly durable prints. The key is to use sublimation aluminum blanks which have a specific polyester coating designed to receive the ink. Without this special coating, the sublimation process will not work on bare aluminum.

How Does Sublimation Work on Aluminum Sheets?

The process involves converting solid sublimation inks into a gaseous state using heat and pressure. These gases then permeate the polyester coating on the aluminum sheet and solidify, becoming a permanent part of the material. This results in a print that is not merely on the surface, but infused into the coating, offering superior durability.

What Temperature Do You Sublimate Aluminum Sheets?

The ideal temperature to sublimate aluminum sheets typically ranges from 385°F to 400°F (196°C to 204°C). The dwell time, or how long the heat is applied, usually falls between 45 to 90 seconds.

- Temperature: Aim for consistent heat across the entire surface.

- Time: Shorter times usually mean less ink penetration, while longer times can lead to color fading or dullness (over-pressing).

- Pressure: Medium to firm pressure is usually required to ensure good contact between the transfer paper and the sublimation blank.

It’s crucial to consult the specific instructions provided by your sublimation aluminum sheet manufacturer, as slight variations can occur based on coating type and thickness. Always perform a test print if unsure.

What is a Sublimation Aluminum Sheet?

A sublimation aluminum sheet is a high-quality aluminum panel specifically designed for the dye-sublimation printing process. Unlike standard aluminum, these sheets are coated with a specialized polyester layer that can absorb sublimation inks when heated. This unique coating is what allows for the transfer of a digital image directly into the aluminum, creating a permanent, scratch-resistant, and incredibly vibrant print. These sheets are often referred to as sublimation blanks because they are ready to receive your custom design.

What is the Price of Aluminium Sublimation Sheet?

The price of aluminium sublimation sheet varies significantly based on several factors:

- Size: Larger sheets are naturally more expensive.

- Thickness: Thicker sheets generally cost more due to increased material.

- Finish: Specialty finishes like brushed silver or gold might be priced higher than standard gloss white.

- Quantity: Bulk purchases often lead to lower per-sheet costs.

- Brand/Manufacturer: Reputable brands might have slightly higher prices but often offer consistent quality.

Generally, small 4″x8″ aluminum sublimation blanks might cost a few dollars each, while larger custom-sized sheets can range from tens to hundreds of dollars. It’s best to check with suppliers for current pricing and bulk discounts.

How to Make a Sublimation Metal Sheet (Printing Process)

When we talk about “making” a sublimation metal sheet in this context, we’re referring to the process of applying your design to a sublimation blank. You don’t manufacture the blank yourself; you transfer your image onto it. Here’s a simplified guide:

- Design Your Image: Create or select your image using graphic design software. Ensure it’s high resolution and remember to mirror (flip horizontally) your design before printing.

- Print Your Design: Use a sublimation printer loaded with sublimation ink and print your mirrored design onto sublimation transfer paper.

- Prepare the Blank: Peel off any protective film from your sublimation aluminum blank. Clean the surface thoroughly to remove dust or fingerprints.

- Position the Print: Securely tape the printed transfer paper, image-side down, onto the coated side of the aluminum sublimation sheet using heat-resistant tape.

- Heat Press: Place the assembly into a heat press.

- Lay a piece of butcher paper or parchment paper on the bottom platen.

- Place the aluminum sheet (with the transfer paper on top) onto the platen.

- Cover with another piece of butcher paper on top to protect the heat press from ink bleed.

- Press: Close the heat press at the recommended temperature and time (e.g., 385-400°F for 45-90 seconds) with medium pressure.

- Cool and Reveal: Once the time is up, carefully remove the aluminum sheet from the press (it will be very hot!). Allow it to cool slightly, then carefully peel off the transfer paper to reveal your vibrant, permanent print.

Sublimation Blank Brushed Silver Aluminum Sheets

Sublimation blank brushed silver aluminum sheets offer a distinct aesthetic. The brushed texture of the aluminum shows through in any unprinted areas, adding a sophisticated, modern, and industrial feel to your images. This finish is perfect for black and white photography, industrial designs, or contemporary art where the metallic undertone enhances the visual appeal. When sublimating on brushed silver, unprinted white areas will appear as the brushed silver of the blank, creating unique visual depth.

4″x8″ Aluminum Sublimation Blank

The 4″x8″ aluminum sublimation blank is a popular and versatile size for many projects. It’s ideal for:

- Small photo prints and desk plaques

- Custom signage for offices or homes

- Decorative tiles

- Personalized gifts and awards

- Craft projects

- Test prints before moving to larger items.

Its compact size makes it easy to handle and press, while still offering enough surface area for meaningful designs.

Applications

The durability, vibrant output, and unique aesthetic of sublimation aluminum sheets make them suitable for a wide array of applications:

- Photography: Creating high-definition, gallery-quality metal photo prints that are scratch-resistant and waterproof.

- Art Reproduction: Producing vivid and lasting reproductions of digital art, illustrations, and paintings.

- Signage: Durable indoor and outdoor signs for businesses, directional signs, and informational plaques.

- Awards and Trophies: Custom awards, plaques, and recognition pieces with stunning detail.

- Decorative Panels: Wall decor, kitchen backsplashes, and decorative inserts for furniture.

- Personalized Gifts: Custom coasters, keychains, luggage tags, and unique memorabilia.

- Architectural Features: Custom panels for interior design, elevator wraps, or decorative accents.

- Memorials: Durable and weather-resistant grave markers or memorial plaques.

- Industrial Labels: High-durability labels for machinery, equipment, and asset tags.

Tips for Best Sublimation Results

- High-Resolution Images: Always start with high-quality, high-resolution images for sharp, clear prints.

- Cleanliness: Ensure your sublimation blank and heat press are free of dust, lint, or debris.

- Ventilation: Work in a well-ventilated area as some fumes may be released during pressing.

- Protective Layers: Use butcher paper above and below the blank to protect your heat press from ink migration.

- Test, Test, Test: If it’s a new material or a large project, always do a small test print to fine-tune your time, temperature, and pressure settings.

Packaging

FAQ Section

Q: How long do sublimated aluminum prints last outdoors?

A: 3-5 years with UV laminate protection.

Q: Can you sublimate both sides?

A: Yes, using double-sided coated sheets.

Q: What printer works best?

A: Epson F170/Sawgrass SG500+ recommended.