Printed aluminium sheets represent a versatile and innovative material that combines the inherent strengths of aluminum with endless design possibilities. These sheets are transforming industries from signage and architecture to packaging and consumer goods, offering durable, lightweight, and visually striking solutions. If you’re looking for a material that stands out, look good, and stands up to the elements, printed aluminum sheets might be your perfect choice.

Specifications

| Property | Details |

|---|---|

| Alloy Options | 1100, 3003, 5052, 6061 |

| Thickness Range | 0.3 mm – 2.0 mm |

| Sheet Sizes | 600×600 mm, 1220×2440 mm, custom sizes |

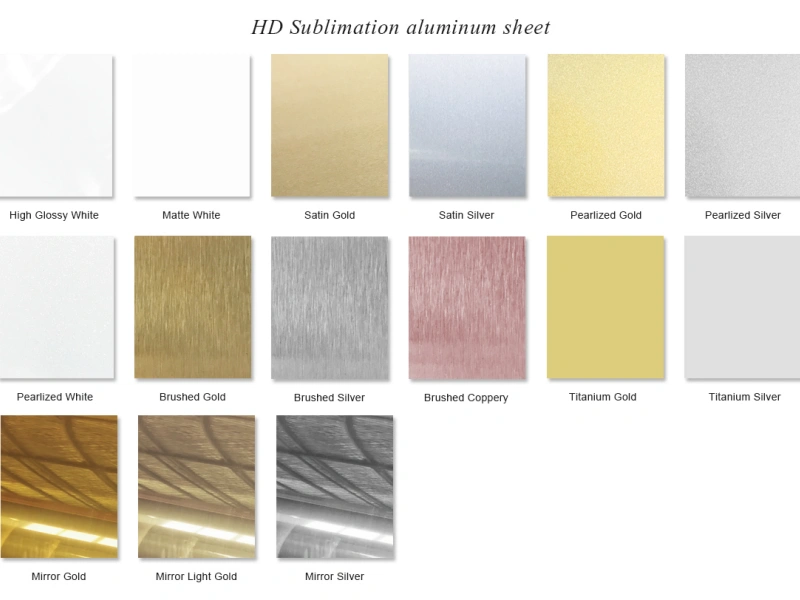

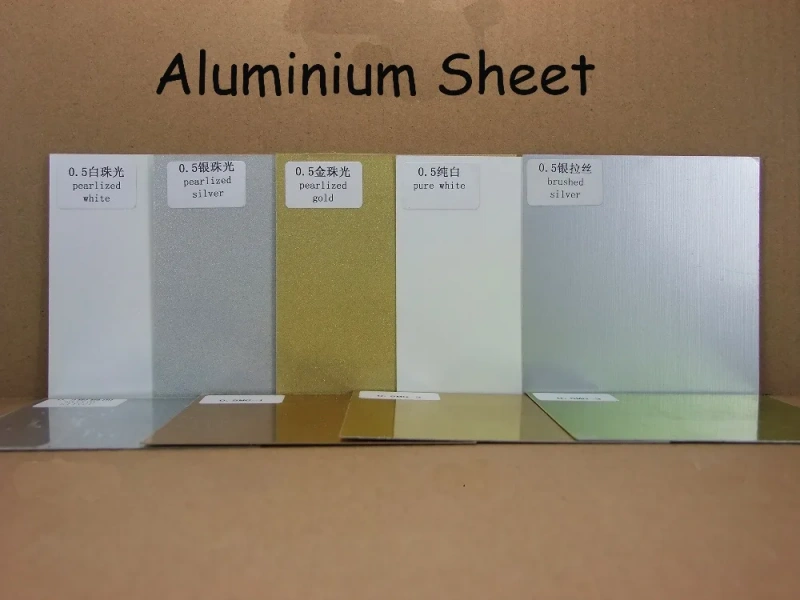

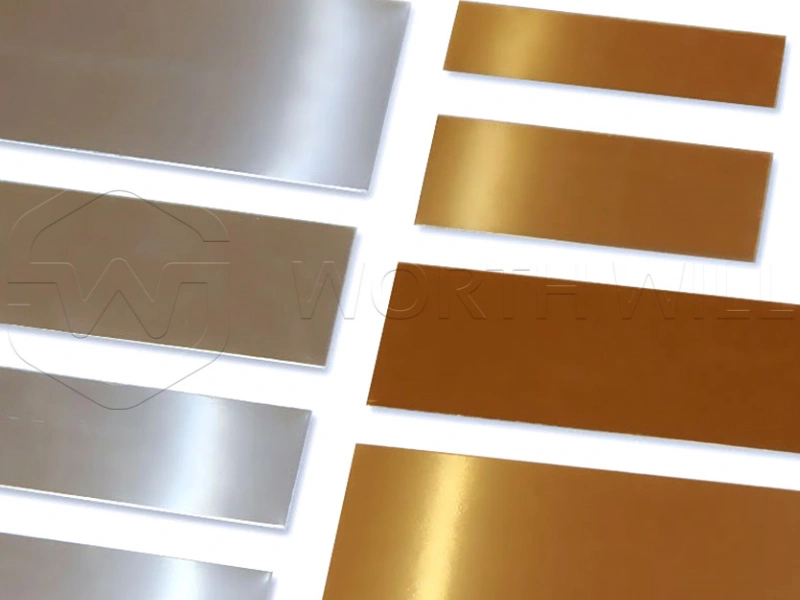

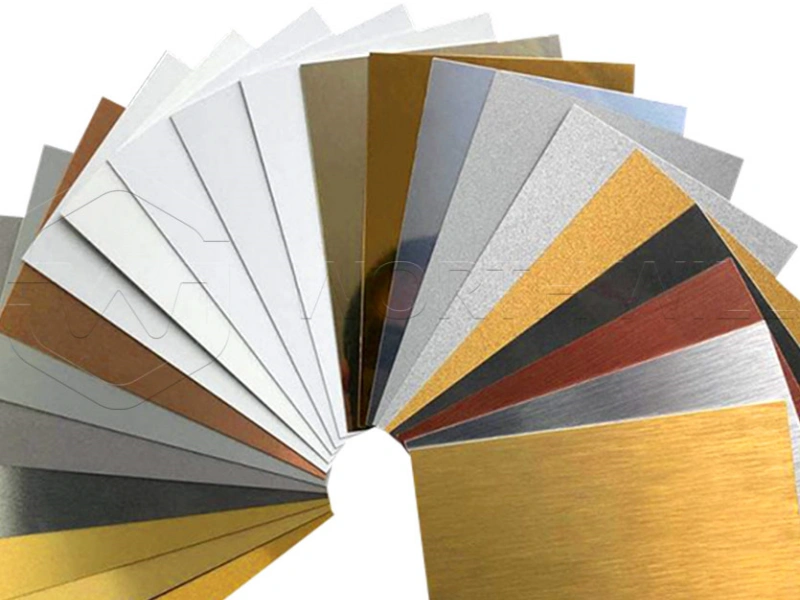

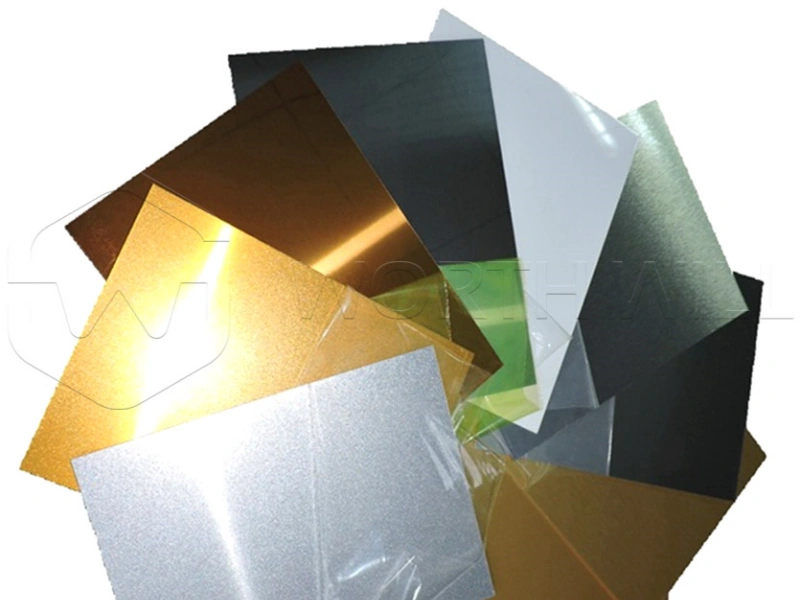

| Finish Options | Glossy, matte, brushed, mirror |

| Printing Method | UV printing, sublimation, screen printing |

| Color Options | CMYK full color, custom logos, textures |

| Protective Film | Available for both sides |

We can also supply sublimation-ready aluminium sheets or pre-coated white aluminum panels for DIY printing projects.

🎨 Types of Printed Aluminium Sheets We Offer

UV Printed Aluminum Sheets

- Direct print on aluminum using UV-curable ink

- Excellent for outdoor signs and nameplates

Sublimation Printed Aluminum

- Image transferred using heat and pressure

- Ideal for photo panels, plaques, personalized gifts

Screen Printed Aluminum

- Cost-effective for large volumes

- Suitable for branding, serial numbers, and logos

Brushed or Mirror Printed Sheets

- Decorative appearance

- Great for luxury signage or furniture panels

In this comprehensive guide, we’ll delve into the specifications, advantages, production processes, and applications of this remarkable material.

Key Specifications of Printed Aluminum Sheets

Understanding the technical aspects is crucial when selecting the right printed aluminum sheets for your project.

Classification

The classification of printed aluminum sheets can be viewed through several lenses, primarily focusing on the printing method, the intended application, and the final surface finish:

- By Printing Method:

- Digital Printing: Allows for high-resolution images, complex graphics, and variable data. Ideal for short runs and custom designs.

- Screen Printing: Best for bold colors, thicker ink layers, and simpler designs, often used for industrial labeling or signs with limited color palettes.

- Offset Printing: Typically used for high-volume production, offering excellent print quality and registration, common in packaging.

- By Application: Decorative panels, signage boards, architectural cladding, packaging components, or electronic casings.

- By Surface Finish: Glossy, matte, satin, or textured, each offering a different aesthetic and functional characteristic (e.g., anti-glare).

Thickness

The thickness of printed aluminum sheets is a critical specification that impacts their rigidity, durability, weight, and suitability for different applications. It is typically measured in millimeters (mm) or gauges.

- Thin Gauges (e.g., 0.2mm – 0.5mm): Often used for packaging (like can bodies, caps), flexible signage, or decorative trims where high flexibility is needed.

- Medium Gauges (e.g., 0.5mm – 2.0mm): Common for general signage, decorative wall panels, exhibition displays, and lightweight architectural applications, offering a good balance of rigidity and formability.

- Thick Gauges (e.g., 2.0mm and above): Utilized for structural signage, robust architectural facades, or industrial components that require significant strength and resistance to bending.

Choosing the appropriate thickness ensures the finished product meets the necessary performance and aesthetic requirements.

Alloy

The alloy of aluminium used profoundly influences the properties of the final printed aluminum sheets, including their formability, corrosion resistance, and suitability for printing.

- 1xxx Series (e.g., 1050, 1100): These are commercially pure aluminum alloys. They offer excellent corrosion resistance and formability, making them ideal for applications requiring deep drawing or intricate shaping, though they are softer.

- 3xxx Series (e.g., 3003, 3105): These alloys contain manganese, which enhances their strength without significantly compromising formability or corrosion resistance. They are widely used for general purposes, including architectural panels and coil-coated products, providing a good balance for printed aluminum sheets.

- 5xxx Series (e.g., 5005): Containing magnesium, these alloys offer higher strength and excellent corrosion resistance, especially in marine environments. They are a good choice when superior durability and resistance to saltwater or harsh outdoor conditions are required for printed aluminum sheets.

The right alloy ensures the sheet can withstand the printing process and perform optimally in its intended environment.

What are the Advantages of Printed Aluminum Sheets?

The benefits of using printed aluminum sheets are numerous, making them a preferred material in many industries:

- Exceptional Aesthetics: They offer vibrant colors, sharp details, and the ability to reproduce complex graphics, photographs, and custom designs, allowing for unparalleled visual impact.

- Durability and Longevity: Aluminum is naturally corrosion-resistant. When combined with high-quality printing and protective coatings, these sheets become highly resistant to scratches, abrasion, UV radiation, moisture, and extreme temperatures, ensuring the design lasts for years.

- Lightweight: Despite their strength, printed aluminum sheets are significantly lighter than many other materials, simplifying handling, installation, and reducing structural load. This also leads to lower transportation costs.

- Corrosion Resistance: Aluminum does not rust, making these sheets ideal for both indoor and outdoor applications, even in harsh or humid environments.

- Recyclability: Aluminum is 100% recyclable without loss of quality, making printed aluminum sheets an environmentally friendly choice and contributing to sustainable practices.

- Versatility: They can be cut, formed, and fabricated into various shapes and sizes after printing, offering flexibility in design and application.

- Customization: The ability to print custom designs means they can perfectly match specific branding, artistic visions, or functional requirements.

What are the Disadvantages of Printed Aluminium Sheets?

While offering many benefits, it’s also important to consider potential drawbacks:

- Initial Cost

- Scratch Sensitivity (without proper coating)

- UV Fading (low-quality prints/coatings)

- Limited Post-Print Forming

How are Printed Aluminum Sheets Made?

The production of printed aluminum sheets involves a meticulous multi-step process to ensure quality and durability:

- Surface Preparation

- Base Coat Application (Optional but Common)

- Printing Process:

- Digital Printing

- Screen Printing

- Offset Printing:

- Ink Curing/Drying

- Protective Top Coat Application

- Final Curing

- Cutting and Fabrication

What is the Difference Between Pre-painted and Printed Aluminum Sheets?

While both pre-painted and printed aluminum sheets involve applying a coating to aluminum, their primary purpose and the complexity of the applied design differ significantly:

- Pre-painted Aluminum Sheets: These sheets are typically produced in a continuous coil-coating process.

- Printed Aluminum Sheets: The focus is on visual communication, branding, intricate aesthetics, or simulating complex materials.

In essence, pre-painted aluminum offers a base color; printed aluminum sheets offer a canvas for detailed artistic and informational expression.

Applications of Printed Aluminium Sheets

The versatility and appealing characteristics of printed aluminum sheets make them suitable for a vast array of applications:

- Signage: Indoor and outdoor signs, advertising boards, directional signs, shop fronts.

- Architectural Cladding: Decorative wall panels, ceiling tiles, facade elements for modern buildings.

- Interior Design: Feature walls, kitchen splashbacks, decorative screens, furniture inserts.

- Packaging: High-end product packaging, specialty cans, bottle caps, cosmetic containers.

- Art and Photography: Direct printing of artwork and photographic reproductions for galleries and homes.

- Consumer Electronics: Front panels for appliances, casings for gadgets, control panels.

- Point-of-Sale Displays: Durable and visually appealing displays for retail environments.

- Transportation: Interior panels for trains, buses, and marine applications.

- Whiteboards and Notice Boards: With a special dry-erase coating, they can serve as functional display surfaces.

- Promotional Items: Custom-designed coasters, keychains, and other branded merchandise.

Conclusion

Printed aluminum sheets are a testament to how modern manufacturing and design can converge to create superior materials. They offer an unparalleled combination of aesthetic flexibility, allowing for vibrant and custom designs, coupled with the inherent durability, lightweight nature, and corrosion resistance of aluminum. Whether for eye-catching signage, sophisticated architectural elements, or premium packaging, these sheets provide a high-performance solution that looks good and lasts. Investing in high-quality printed aluminum sheets ensures your project benefits from a material that is not only visually striking but also robust, sustainable, and built to endure.