Anodized aluminum is widely known for its durability, corrosion resistance, and sleek appearance. However, some projects may require additional protection or a specific color finish, which can be achieved through powder coating. Powder coating over anodized aluminum is a popular solution for enhancing both the aesthetics and longevity of aluminum products. But is it the right choice for your application?

What is Powder Coating?

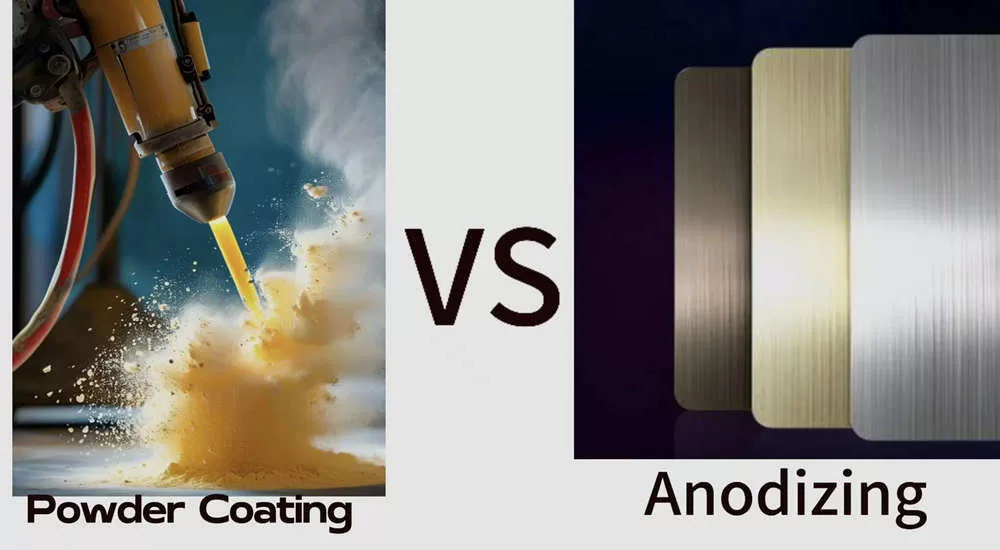

Powder coating is a dry finishing process where a powdered pigment is applied to a metal surface using electrostatic spray deposition. The powder is then cured under heat, which melts the particles and forms a smooth, durable finish. Powder coating offers a wide range of color options, textures, and finishes, making it a highly versatile method for metal finishing.

What is Anodized Aluminum?

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of aluminum. This layer protects the aluminum from corrosion, wear, and oxidation, while providing a smooth, metallic finish. Anodized aluminum is commonly used in architectural, automotive, and consumer products due to its durability and attractive appearance.

Why Powder Coat Over Anodized Aluminum?

Powder coating anodized aluminum provides several advantages that can enhance the performance and appearance of the material.

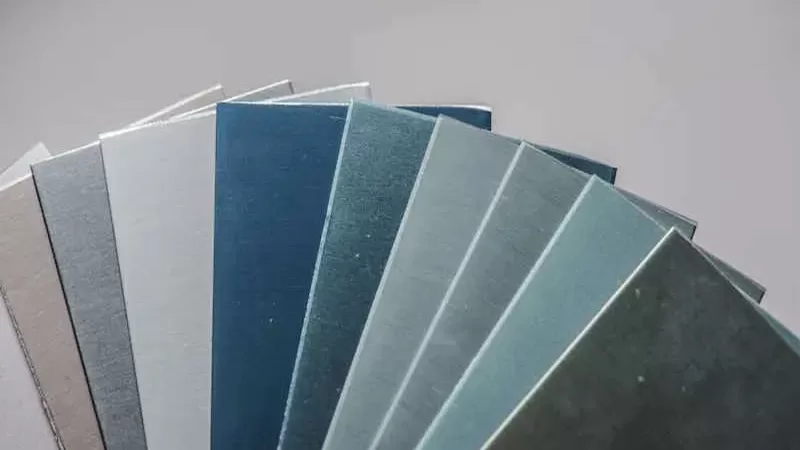

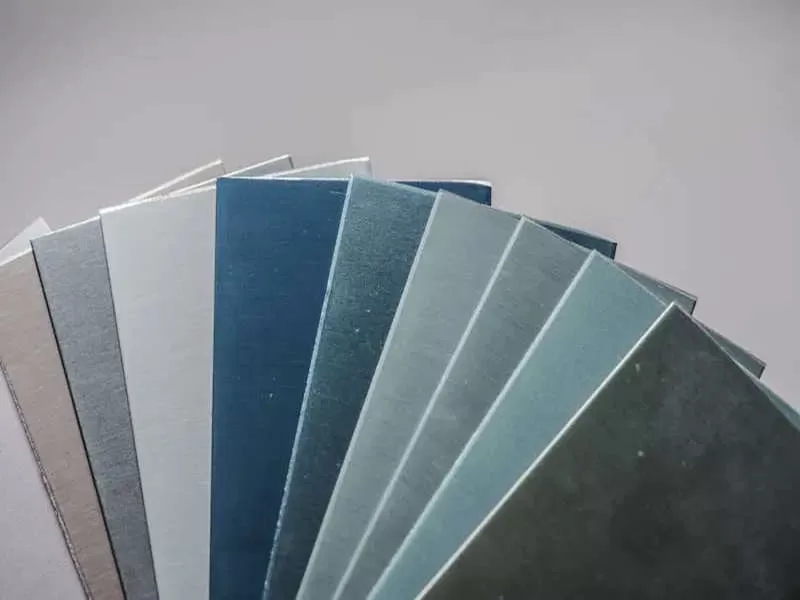

- Enhanced Aesthetics While anodized aluminum offers a sleek, metallic finish, powder coating allows for a wide range of colors and finishes that anodizing alone cannot provide. Whether you want a glossy, matte, or textured surface, powder coating adds a unique visual appeal to anodized aluminum. This is ideal for projects that require a specific look or branding.

- Additional Corrosion Resistance Anodizing already provides excellent corrosion resistance, but powder coating adds an additional protective layer. This double-layer protection is especially useful in harsh environments, such as coastal areas or industrial settings, where aluminum may be exposed to saltwater, chemicals, or extreme weather conditions.

- Increased Durability Powder coating creates a thicker and more impact-resistant layer compared to paint, helping anodized aluminum better withstand dents, scratches, and abrasions. This makes powder-coated anodized aluminum a durable option for high-traffic areas or applications where the material may be subject to rough handling.

- UV and Weather Protection The combination of anodizing and powder coating provides enhanced protection against UV radiation and weathering. While anodized aluminum is already resistant to fading and chalking from sun exposure, powder coating further increases the material’s ability to resist UV damage, ensuring that the color and finish remain vibrant over time.

- Customization Options One of the major benefits of powder coating over anodized aluminum is the ability to customize the finish to match your project’s exact needs. Powder coatings can be formulated to provide specific textures, such as rough, smooth, or wrinkle finishes, and can even replicate the look of anodized surfaces while offering different colors.

Challenges of Powder Coating Over Anodized Aluminum

While powder coating over anodized aluminum offers many benefits, there are also some challenges to consider:

- Surface Preparation Proper surface preparation is essential to ensure good adhesion between the powder coating and the anodized aluminum. If the anodized layer is too smooth, the powder coating may not adhere properly, leading to peeling or flaking. The surface may need to be lightly sanded or etched to create enough texture for the powder to bond effectively.

- Increased Thickness Powder coating adds an extra layer to the anodized aluminum, which can increase the overall thickness of the material. For applications where tight tolerances are required, such as in precision-machined parts, this increased thickness may cause issues with fit or function.

- Cost Considerations Anodizing and powder coating are both cost-effective finishing processes on their own, but combining them adds to the overall cost. For some projects, the added durability and aesthetic benefits may outweigh the extra expense, but it’s important to evaluate whether both processes are necessary for your application.

- Potential for Color Mismatch If you’re trying to match the color of the powder coating with the underlying anodized layer, it can be challenging to achieve an exact match. This is especially true if the anodized finish is clear or has a unique hue. However, with the proper formulation and testing, color consistency can be achieved.

Best Practices for Powder Coating Over Anodized Aluminum

To ensure a successful powder coating application over anodized aluminum, here are some best practices to follow:

- Surface Preparation

Lightly sand or etch the anodized surface to promote better adhesion of the powder coating. Avoid over-sanding, as this could damage the anodized layer. - Use High-Quality Powders

Choose high-quality powder coatings specifically designed for aluminum substrates. Some powder coatings are formulated for better adhesion to anodized surfaces, providing better results and durability. - Apply Even Coating

Ensure an even and consistent application of powder to avoid uneven surfaces or color variations. Use proper spraying techniques and control the thickness of the powder to prevent issues with fit or function. - Curing Process

Follow the manufacturer’s guidelines for curing temperatures and times to ensure the powder coating properly bonds to the anodized aluminum. Proper curing is critical for achieving a smooth and durable finish.

Applications for Powder Coated Anodized Aluminum

Powder coating over anodized aluminum is used in various industries, including:

- Architectural: For window frames, curtain walls, and exterior facades that require a specific color and enhanced weather resistance.

- Automotive: For custom parts, trim, and accessories that require additional protection and a custom finish.

- Marine: For boat fittings and hardware that are exposed to harsh saltwater environments.

- Consumer Products: For appliances, furniture, and electronics where aesthetics and durability are important.

Conclusion

Powder coating over anodized aluminum is a smart choice for projects that require additional protection, durability, and aesthetic customization. While there are some challenges, such as surface preparation and cost considerations, the benefits of improved corrosion resistance, durability, and design flexibility make this combination an ideal solution for many applications. By following best practices and selecting the right materials, you can achieve a high-quality, long-lasting finish that meets the demands of your project.