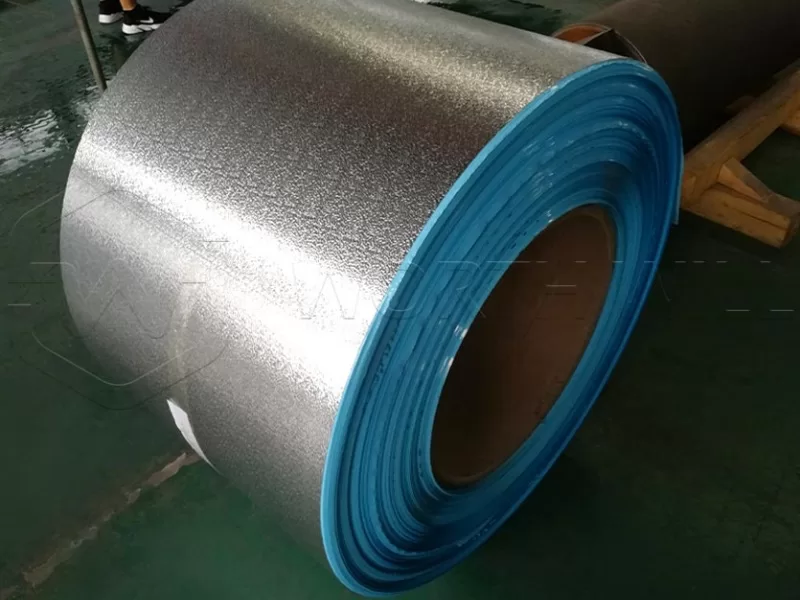

Plain PSMB ( plain aluminium jacketing with PSMB) is a flat steel sheet coated with a layer of protective paint. It offers good corrosion resistance, clean appearance, and easy formability.

Specifications

| Parameter | Details |

|---|---|

| Base Material | Aluminum 1100, 3003, or 5052 |

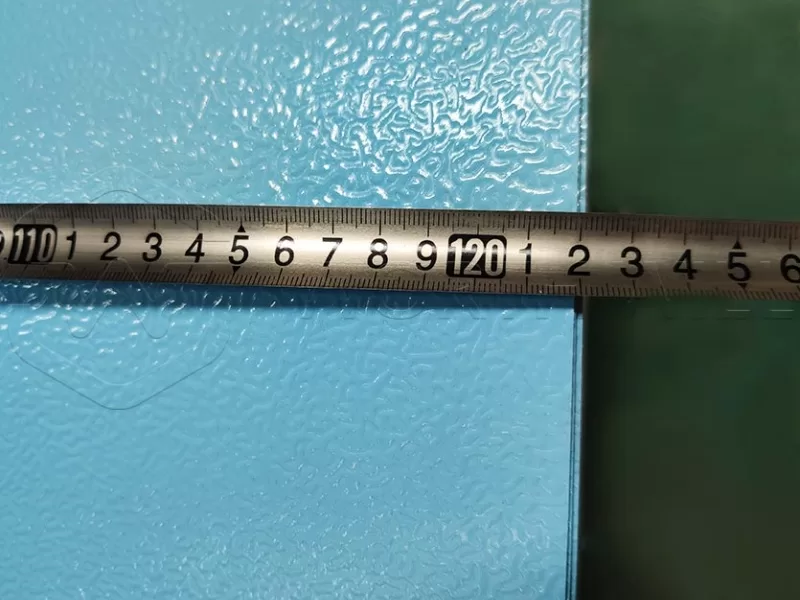

| Thickness | 0.2mm – 1.0mm |

| PSMB Layer | 50-100 micron Polysurlyn film |

| Width | 1000mm – 1500mm (customizable) |

| Temper | H14, H16, H18, O |

| Surface Finish | Mill finish or coated |

Key Features

100% Waterproof – Impermeable moisture barrier

Temperature Resistance – Stable from -40°C to 150°C

Easy Installation – Can be welded or mechanically fastened

Chemical Resistance – Withstands oils and mild acids

Types

1. Standard Plain PSMB

- For general moisture protection

- Common thickness: 0.5mm

2. Fire-Rated Plain PSMB

- Meets building fire codes

- Used in commercial construction

3. Insulated Plain PSMB

- With additional foam backing

- For thermal and acoustic insulation

Applications

Construction Industry

- Roof underlayment

- Wall vapor barriers

- Foundation waterproofing

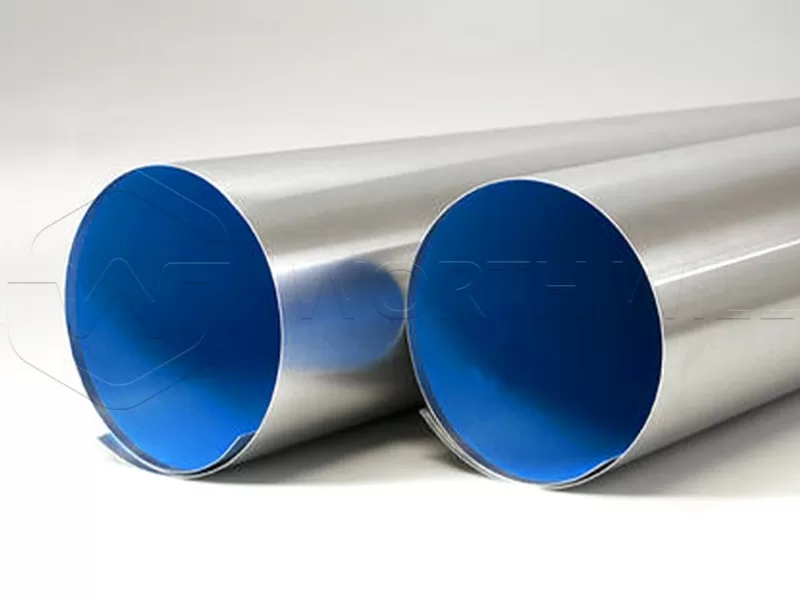

Industrial Uses

- Chemical tank linings

- Pipe insulation jackets

- Equipment enclosures

Transportation

- RV and trailer roofing

- Marine compartment lining

Why Choose Plain PSMB Over Traditional Materials?

| Feature | Plain PSMB | Traditional Moisture Barriers |

|---|---|---|

| Lifespan | 20+ years | 5-10 years |

| Installation | Easy single-layer application | Multiple layers required |

| Maintenance | Virtually none | Regular inspections needed |

| Cost | Higher initial cost | Lower initial but higher lifetime cost |

Installation Guide

- Surface Preparation

- Clean and dry substrate

- Remove sharp protrusions

- Application Methods

- Adhesive bonding (for walls)

- Mechanical fastening (for roofs)

- Heat welding (for seams)

- Sealing

- Use PSMB-compatible sealant

- Overlap edges by at least 50mm

Frequently Asked Questions

Q: Can PSMB be painted?

A: Yes, with compatible epoxy or polyurethane paints after proper surface preparation.

Q: How does it compare to PVC membranes?

A: PSMB offers better UV resistance and higher temperature tolerance.

Q: What’s the expected service life?

A: 20-25 years in normal conditions, 15+ years in harsh environments.

Q: Is it environmentally friendly?

A: Yes, aluminum is fully recyclable and PSMB contains no heavy metals.

Maintenance Tips

- Annual Inspection: Check for physical damage

- Cleaning: Mild detergent and soft brush

- Repairs: Patch with same material and sealant

Packaging Options

- Standard: Wooden crates with moisture-proof wrapping

- Export: Seaworthy containers with desiccants

- Custom: Pre-cut kits with installation manual

Ordering Information

Minimum Order Quantities:

- 100m² for standard products

- 500m² for custom specifications

Lead Times:

- 7 days for stock items

- 14-21 days for custom orders

Why Our Plain PSMB?

Factory-direct pricing

Technical support available

Quality certifications (ISO 9001, ASTM)

Custom fabrication services

What is Plain PSMB?

PSMB (Polysurlyn Moisture Barrier) is a specialized aluminum sheet laminated with a moisture-resistant polymer film. This innovative material combines:

Aluminum’s durability – Corrosion and UV resistance

PSMB’s protection – Complete waterproof barrier

Versatile applications – From construction to industrial uses

Conclusion

Plain PSMB represents the next generation of moisture protection, combining aluminum’s strength with advanced polymer technology. Whether for construction projects or industrial applications, it delivers unmatched performance and longevity.

Packaging

To protect the product during shipping:

- Protective film: Applied to surface to avoid scratches

- Waterproof paper and steel wrapping: Prevents moisture damage

- Wooden pallets or steel frame packaging: Ensures safe handling

Why Choose Our Plain PSMB?

Wide range of coatings and colors

Over 10 years of manufacturing experience

Reliable supply chain and competitive price

Fast response and after-sales service