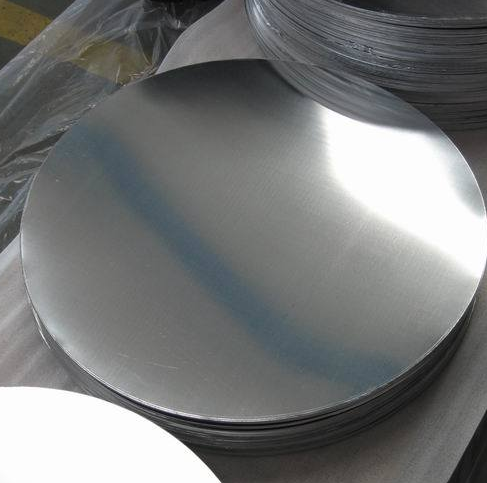

Knowledge of Aluminum Circle

Aluminum circles are widely used in electronics, daily chemicals, medicine, culture and education, automotive applications, electrical appliances, heat preservation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other industries. Such as kitchen utensils, titanium, pressure cooker, water heater, etc., is a deep-processing product with a large amount of aluminum alloy strip.

The properties of aluminum discs make them ideal for use in many markets, including the cookware, automotive and lighting industries, with the following performance advantages:

Aluminum circle for stretching: It’s processed by continuous stamping equipment. Our company stamps directly on aluminum coils, which has the advantage of fast processing cycle. At the same time, the stamping process is completed automatically, so the surface finish is better. Currently, we have 200mm The stamping die between -800mm can be stamped to produce various tensile and aluminum disc materials for containers. The above products are all hot-rolled series, which have the advantages of high elongation and good anodizing effect. This type of aluminum wafer is mainly used in various kitchen utensils, cooking utensils, containers, etc. The minimum order quantity of this type of product must reach more than 1 ton.

Aluminum discs for traffic signs: At the same time, our company also has aluminum disc cutting equipment. This equipment is mainly used for the production of traffic signs for traffic signs and sign companies. It adopts H14 semi-hard state. The processing procedure is that the aluminum plate is cut by the disc cutting equipment after shearing. This equipment has the advantages of high processing precision and adjustable diameter. There is no clear requirement for the minimum order quantity of this type of product.

Characteristics of aluminum discs

1. High strength and good form-ability and corrosion resistance.

2. Customize available include wide diameter of the wafer, and special shapes and sizes.

3. Excellent reflectivity and good polishing effect.

4. Good drawing and spinning quality.

5. Good anode quality, suitable for hard anodizing and enamel.

6. Clean surface and smooth edges, hot-rolled quality, grain refinement and no ring-fitting lines after deep drawing.

7. Excellent pearl color anodizing.

8. Firm packaging