When selecting aluminum for a project, understanding its specific properties is crucial for success. Among the many aluminum tempers, H14 aluminum stands out as a widely used and versatile option, particularly in sheet and coil forms. Known for its excellent balance of strength and formability, combined with good corrosion resistance. H14 aluminum specifications make it an ideal choice for a diverse range of applications where moderate strength and ease of fabrication are desired.

Understanding these H14 aluminum specifications is key to leveraging its full potential in manufacturing, construction, and other industries.

H14 Aluminum Specifications

| Property | Description |

|---|---|

| Temper | H14 (half-hard) |

| Common Alloys | 1100-H14, 3003-H14, 3004-H14, 3105-H14 |

| Thickness Range | 0.2 mm to 6.0 mm (custom on request) |

| Width Range | 20 mm to 1500 mm |

| Tensile Strength | 120–185 MPa (depending on alloy) |

| Elongation (%) | Typically 1%–10% |

| Corrosion Resistance | Excellent in most environments |

| Finish Options | Mill finish, brushed, anodized, coated |

🧪 Mechanical Properties by Alloy

🔩 3003-H14 Aluminum Sheet

- Tensile Strength: 130–160 MPa

- Yield Strength: ≥ 120 MPa

- Elongation: 5%–10%

🔩 1100-H14 Aluminum Sheet

- Tensile Strength: 110–145 MPa

- Yield Strength: ≥ 95 MPa

- Elongation: 3%–7%

These values can vary depending on thickness and processing method. Always confirm with your supplier.

Specification: Alloy

It is important to clarify that H14 is a temper designation, not an alloy itself. The H14 temper can be applied to various non-heat-treatable aluminum alloys. The specific alloy combined with the H14 temper dictates the material’s precise mechanical properties, workability, and corrosion resistance. Some of the most common aluminum alloys found in the H14 temper include:

1100-H14 Aluminum

This is commercially pure aluminum (at least 99% aluminum). When in the H14 temper, 1100 offers:

- Excellent Formability: Very ductile and easy to form, bend, and draw without cracking.

- High Thermal and Electrical Conductivity: Making it suitable for electrical applications and heat exchangers.

- Superior Corrosion Resistance: Excellent resistance to atmospheric corrosion, making it durable in various environments.

- Low Strength: It is one of the softer aluminum alloys, so it’s used where strength is not the primary requirement.

- 3003-H14 Aluminum

- This is an aluminum-manganese alloy, where manganese is added to increase its strength. 3003-H14 is arguably the most common and widely used H14 aluminum specification due to its balanced properties:

- Good Strength: Significantly stronger than 1100-H14, providing better structural integrity for many applications.

- Excellent Workability: Retains good formability, allowing for easy deep drawing, spinning, and welding.

- Very Good Corrosion Resistance: Offers reliable protection against corrosion in general atmospheric conditions.

- General Purpose: Its combination of moderate strength, good formability, and corrosion resistance makes it ideal for a vast array of general fabrication needs.

- 5052-H14 Aluminum

- This is an aluminum-magnesium alloy, known for its higher strength among the non-heat-treatable alloys. When in the H14 temper, 5052 offers:

- Higher Strength: Considerably stronger than both 1100-H14 and 3003-H14.

- Excellent Corrosion Resistance in Marine Environments: Its magnesium content provides superior resistance to saltwater corrosion, making it ideal for marine and coastal applications.

- Good Formability: While stronger, it still possesses good forming characteristics.

The selection of the specific alloy (e.g., 1100, 3003, or 5052) for H14 aluminum largely depends on the required strength, environmental exposure, and specific fabrication methods.

Specification: Classification

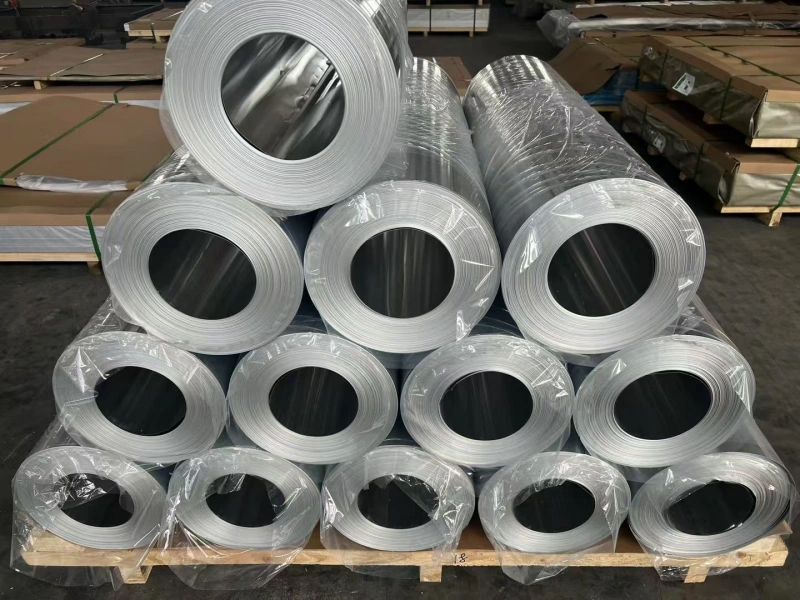

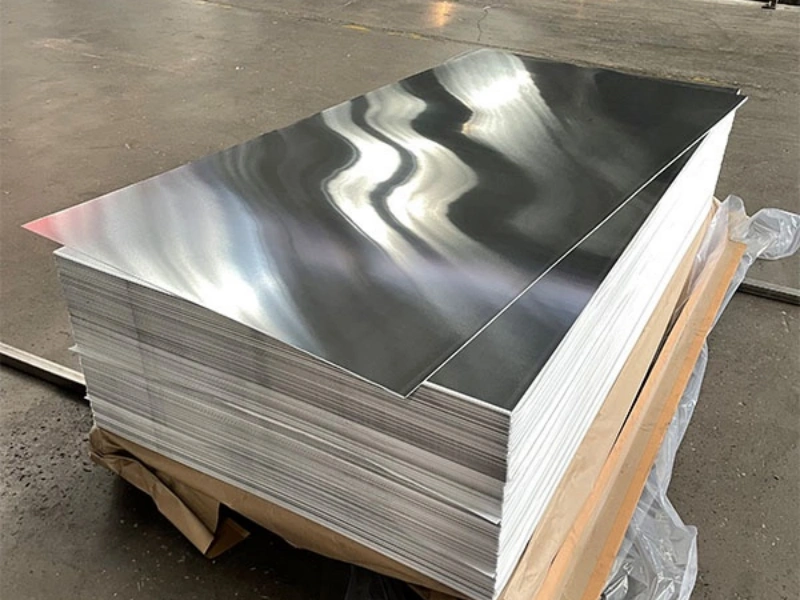

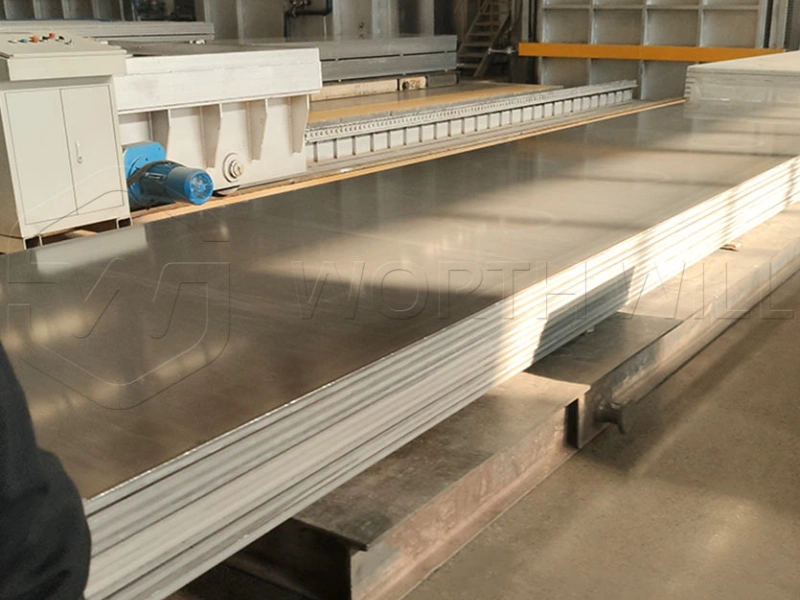

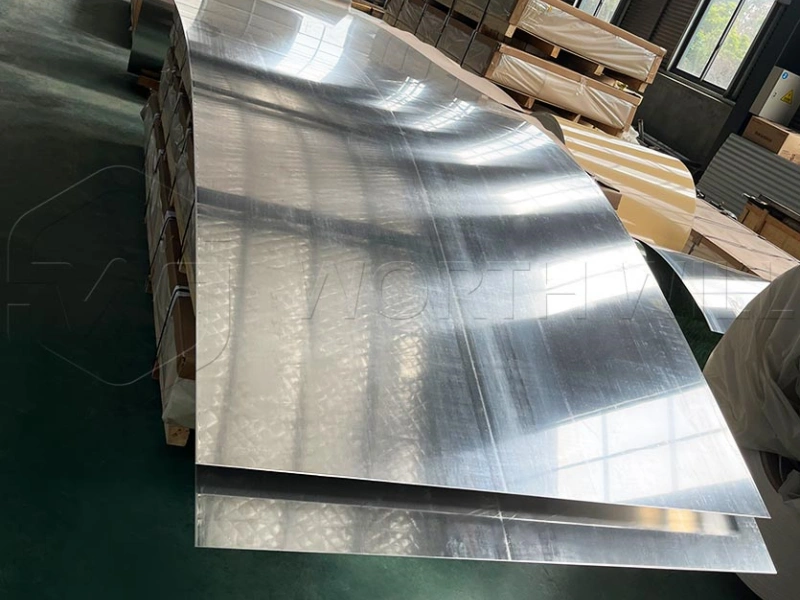

The classification of H14 aluminum primarily refers to the forms in which this temper is commercially available and used. Given its properties, H14 aluminum is most commonly produced and classified as:

- Sheet and Plate: This is the most prevalent form. H14 aluminum sheet is widely used in applications requiring flat or formed panels.

- Coil Stock: For continuous manufacturing processes, H14 aluminum is often supplied in large coils, allowing for efficient, high-volume production of components.

- Blanks and Circles: Pre-cut shapes from H14 sheet or coil, designed for specific manufacturing operations such as deep drawing or stamping.

Its “quarter-hard” state provides this optimal balance, making it a preferred choice over softer (O temper) or harder (H16, H18) tempers for many general-purpose applications.

Specification: Thickness

The thickness of H14 aluminum is a crucial specification, as it directly impacts the material’s weight, overall rigidity, and suitability for various applications. H14 aluminum is typically available in a wide range of thicknesses, primarily for sheet and coil products:

- Thin Gauges (e.g., 0.010 inches to 0.063 inches / 0.25 mm to 1.6 mm): These thinner sheets are highly formable and lightweight, commonly used for ductwork, flashing, general fabrication, and components where weight is a concern.

- Medium Gauges (e.g., 0.063 inches to 0.125 inches / 1.6 mm to 3.175 mm): These offer increased rigidity and strength, making them suitable for more robust panels, small tanks, and semi-structural applications.

- Thicker Plates (e.g., above 0.125 inches / 3.175 mm):

Key Properties of H14 Aluminum

Beyond its specific alloy and thickness, the H14 temper itself imparts several key properties that make this material highly valued:

- Moderate Strength: Offers improved strength over annealed (soft) aluminum without sacrificing significant ductility, making it durable for many applications.

- Excellent Formability and Workability: Its quarter-hard temper allows for good bending, shallow drawing, stamping, and welding characteristics.

- Good Corrosion Resistance: Inherits the excellent corrosion resistance from its base alloys (e.g., 1100, 3003, 5052), making it suitable for both indoor and outdoor use.

- Good Surface Finish: Often provides a smooth and clean surface, which can be easily painted, anodized, or left as is for aesthetic purposes.

- Non-Heat Treatable: Its strength is derived purely from cold working, meaning it cannot be further strengthened by heat treatment. This simplifies processing for many manufacturers.

Applications of H14 Aluminum

The balanced properties of H14 aluminum make it suitable for a vast array of applications across various industries:

- Building and Construction:

- Roofing, siding, and flashing

- Ductwork and ventilation systems

- General architectural trim and panels

- Automotive Industry:

- Non-structural body panels

- Interior components

- Heat shields and general fabrication

- Cookware and Food Service:

- Pots, pans, and other cooking utensils (especially 3003-H14 due to its excellent thermal conductivity and food safety)

- Food processing equipment

- Chemical and Petrochemical:

- Tanks and vessels for chemicals (due to good corrosion resistance)

- Piping and tubing

- General Fabrication and Manufacturing:

- Sign blanks and nameplates

- Appliance components

- Furniture parts

- Consumer electronics casings

- Electrical Applications (especially 1100-H14):

- Bus bars

- Heat sinks

- Marine Applications (especially 5052-H14):

- Boat parts and components exposed to saltwater

Why Choose H14 Aluminum?

The decision to use H14 aluminum is often driven by a need for material that is:

- Easy to Work With: Its good formability and weldability reduce manufacturing complexity and costs.

- Corrosion Resistant: Offers reliable performance in a variety of environments without needing extensive protective coatings.

- Cost-Effective: Often a more economical choice when high strength heat-treatable alloys are not required.

- Lightweight: Contributes to lighter overall product weight, important in industries like automotive and aerospace.

- Versatile: Its balanced properties make it adaptable to a wide range of product designs and functional requirements.

H14

The “H14” designation refers to the temper of the aluminum, which describes its mechanical properties, particularly its hardness and strength, achieved through strain hardening. This temper is applied to various non-heat-treatable aluminum alloys, meaning their strength is increased by cold working rather than by heat treatment.

The “H” indicates strain hardening, the “1” signifies that it has been strain hardened only, and the “4” indicates that it has been hardened to a quarter-hard temper. This means it has been cold worked to approximately one-quarter of the way to its maximum possible strength from its fully annealed (soft) state.

Comparison with Other Tempers

| Characteristic | H14 | H12 | H16 | H18 |

|---|---|---|---|---|

| Strength | Medium | Low | High | Very High |

| Formability | Good | Excellent | Fair | Poor |

| Cost | $$ | $ | $$$ | $$$$ |

| Common Uses | General purpose | Deep drawing | Structural | Specialty apps |

Frequently Asked Questions

1. Can H14 aluminum be welded?

Yes, all common alloys in H14 temper can be welded using standard aluminum welding techniques.

2. How does H14 compare to T6 temper?

H14 is cold-work hardened while T6 is solution heat treated. T6 offers higher strength but H14 is more formable and cost-effective.

3. What’s the maximum service temperature?

Typically up to 150°C (300°F) for continuous service, though this varies by alloy.