As a leading factory specializing in blue anodized aluminum sheet, we combine advanced technology with strict quality control to deliver products that meet global standards. Our sheets are known for their consistent color, excellent corrosion resistance, and long-lasting performance.

Classification of Blue Anodized Aluminum Sheets

Blue anodized sheets are available in multiple grades and surface types.

| Classification | Description |

|---|---|

| Brushed Anodized Aluminum | Matte finish with fine lines |

| Polished Anodized Aluminum | Glossy surface for decorative use |

| Embossed Anodized Aluminum | Textured for anti-slip and visual effect |

| Colored Anodized Aluminum | Multiple shades including blue, red, gold |

Thickness Options

Thickness impacts strength, weight, and usage.

| Thickness (mm) | Common Application |

|---|---|

| 0.3 – 0.5 | Labels, signs, lightweight panels |

| 0.6 – 1.0 | Decorative panels, appliance covers |

| 1.2 – 2.0 | Automotive, industrial parts |

| 2.5 – 5.0 | Structural, heavy-duty applications |

Alloy Grades for Blue Anodized Aluminum Sheet

Different alloys provide different strength and corrosion resistance levels.

| Alloy | Features | Applications |

|---|---|---|

| 1050 | High purity, soft, easy to anodize | Signs, nameplates, decoration |

| 3003 | Good corrosion resistance | Roofing, interior decoration |

| 5052 | High strength, marine grade | Automotive, marine equipment |

| 6061 | Excellent machinability, strong | Aerospace, industrial machinery |

Types of Blue Anodized Aluminum Sheets

- Plain anodized sheets – simple, protective coating

- Decorative blue anodized sheets – used for panels and interiors

- Hard-anodized sheets – extra durability for industrial use

- Custom patterned anodized sheets – branding and design applications

Why Choose Our Factory for Blue Anodized Aluminum Sheets?

Unlike many suppliers, our company provides direct factory service with long-term production experience.

Our advantages:

- Fast & Accurate Production: Modern equipment ensures stable quality.

- Reliable Quality: Every sheet passes strict inspection before delivery.

- Reasonable Price: Direct factory sales reduce middle costs.

- Experienced Team: 20+ years of aluminum production.

- Trusted by Customers Worldwide: Long cooperation with global partners.

- Flexible Customization: Sizes, thickness, and surface treatment tailored to your project.

Compared with other factories:

- We provide shorter lead time.

- We guarantee consistent surface color with anodizing.

- We offer after-sales service and long-term support.

Factory Overview

Our anodizing production line has the capacity to produce tons of blue anodized aluminum sheets every month. With advanced coating technology, we ensure color uniformity, scratch resistance, and durability.

Key factory strengths:

- ISO-certified production process

- High-quality anodizing tanks and rollers

- Professional QC team

- Fast delivery for both small and bulk orders

Packaging of Blue Anodized Aluminum Sheets

To ensure safe transportation, our sheets are packed as follows:

- Protective film on surface

- Kraft paper or plastic wrapping

- Wooden pallets or boxes for export

- Steel straps for secure shipment

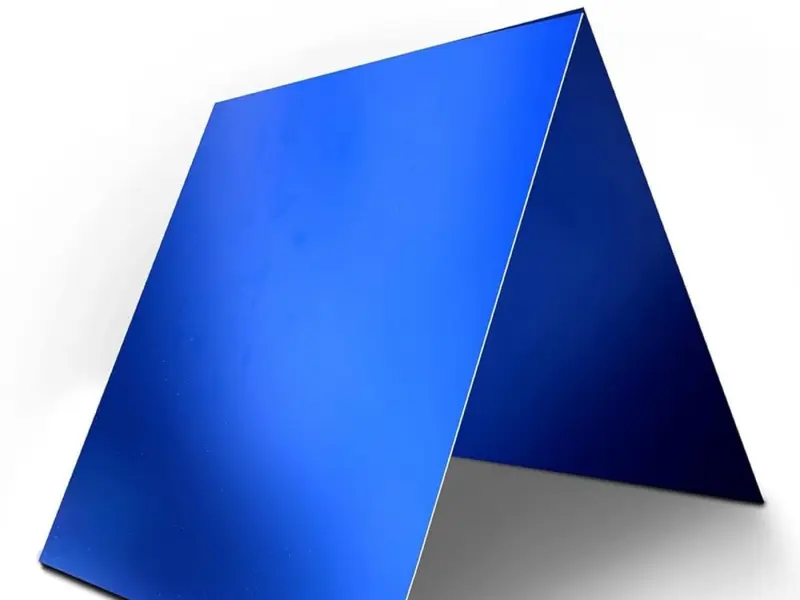

What Is Blue Anodized Aluminum Sheet?

Blue anodized aluminum sheet is an aluminum sheet that has been treated with an anodizing process to create a protective oxide layer and a decorative blue finish. This process improves corrosion resistance, surface hardness, and appearance.

It is widely used in:

- Architectural decoration

- Electronic enclosures

- Signage and nameplates

- Automotive parts

- Interior and exterior design

Applications of Blue Anodized Aluminum Sheet

Blue anodized aluminum is chosen for both functional and decorative purposes.

- Building decoration – walls, ceilings, panels

- Electronics – mobile phone cases, laptops, speaker covers

- Transportation – automotive panels, marine parts

- Signage and advertising – display boards, logos, traffic signs

- Furniture – cabinets, kitchen decoration, interior design

Why Choose Our Blue Anodized Aluminum Sheet?

1. Trusted Manufacturing Expertise

- 20+ years of experience in anodized aluminum production

- ISO 9001 certified factory with annual capacity of 50,000 tons

- Long-term partnerships with clients in 30+ countries

2. Precision & Efficiency

- Quick response within 2 hours for quotations

- 15-day average production time (faster than industry average)

- Accurate thickness tolerance (±0.02mm) and color consistency

3. Competitive Advantages

- Direct factory pricing (15-20% lower than traders)

- Custom sizes and shades of blue available

- Eco-friendly anodizing process (RoHS compliant)

FAQ – Frequently Asked Questions

Q1: What is anodized aluminum sheet used for?

A: It is used for decoration, corrosion resistance, and protective surfaces in multiple industries.

Q2: What is the difference between anodized aluminum and painted aluminum?

A: Anodized aluminum is more durable and wear-resistant, with color locked into the surface layer. Painted aluminum can peel or fade over time.

Q3: Can you customize thickness and size?

A: Yes, we provide custom sizes from 0.3 mm to 5.0 mm thickness and various widths/lengths.

Q4: Why choose blue anodized aluminum over natural anodized aluminum?

A: Blue anodized aluminum offers a stylish, modern look while keeping the same corrosion resistance.

Q5: How long does the anodized color last?

A: With proper use, anodized color remains stable for 15–20 years without fading.