If you’re searching for a durable, lightweight, and modern solution, an aluminium roofing sheet is an excellent choice. This guide will help you understand why aluminium stands out and how to find the best aluminium roofing sheet for your needs, covering everything from design to thickness and alloys.

Classification

Aluminium roofing sheets are among the most popular roofing materials worldwide. They are lightweight, corrosion-resistant, durable, and easy to install. Based on surface finish, thickness, and alloy, aluminium sheets are classified into:

- Plain aluminium roofing sheets

- Corrugated aluminium roofing sheets

- Color-coated aluminium sheets

- Embossed aluminium roofing sheets

Thickness

The thickness of aluminium roofing sheets determines their durability and performance. Thicker sheets are stronger and last longer, while thinner sheets are more economical and lighter.

Table: Common Thickness Options

| Thickness (mm) | Typical Use Case | Durability Level |

|---|---|---|

| 0.25 – 0.35 | Temporary roofing, sheds, small huts | Light |

| 0.40 – 0.50 | Residential houses, small shops | Medium |

| 0.60 – 0.80 | Warehouses, schools, offices | Strong |

| 1.0 and above | Industrial, factories, long-span roofs | Extra Strong |

Alloy

Aluminium roofing sheets are available in different alloys. Each alloy has unique properties suited for specific environments.

Common Roofing Alloys

| Alloy | Features | Best Application |

|---|---|---|

| 1050 | High purity, lightweight | Low-cost roofing, rural housing |

| 3003 | Excellent corrosion resistance | Coastal and humid areas |

| 5052 | High strength, marine grade | Industrial and marine roofing |

| 8011 | Strong formability, cost-effective | Residential and commercial roofing |

Types

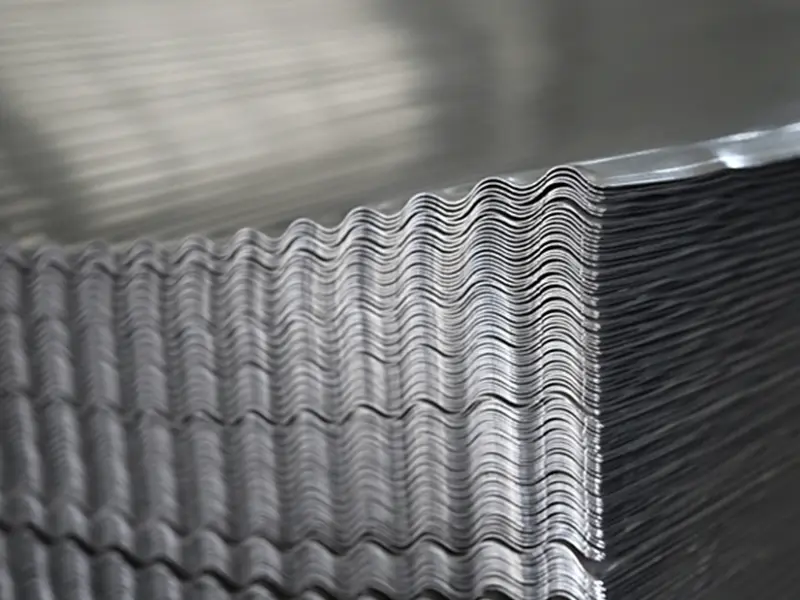

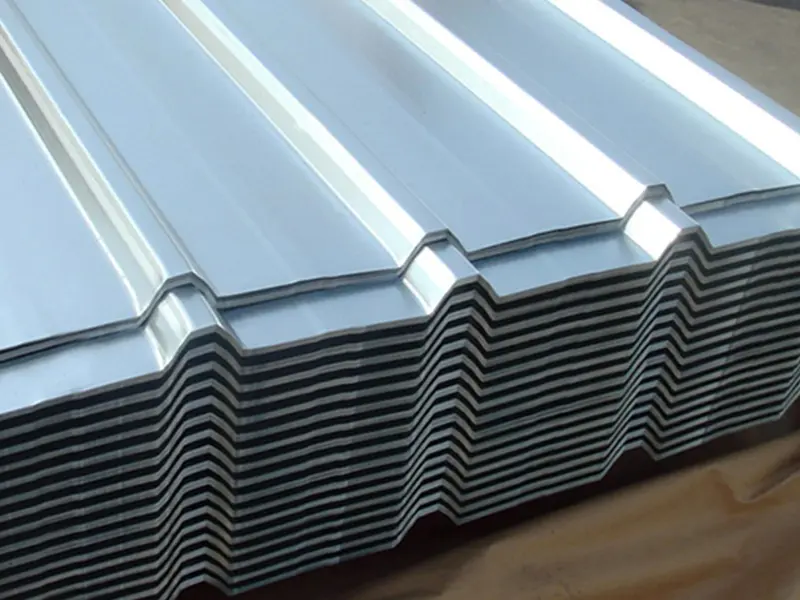

- Corrugated aluminium roofing sheet: Traditional style, strong and economical.

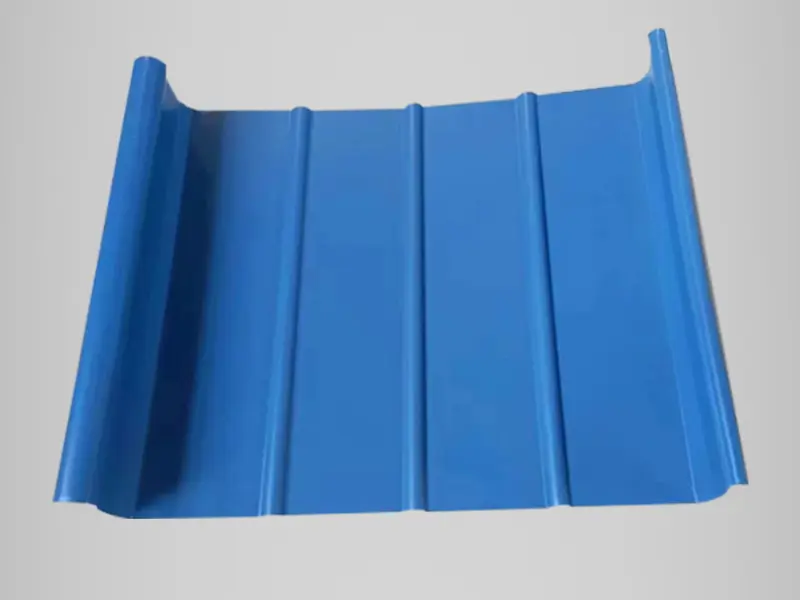

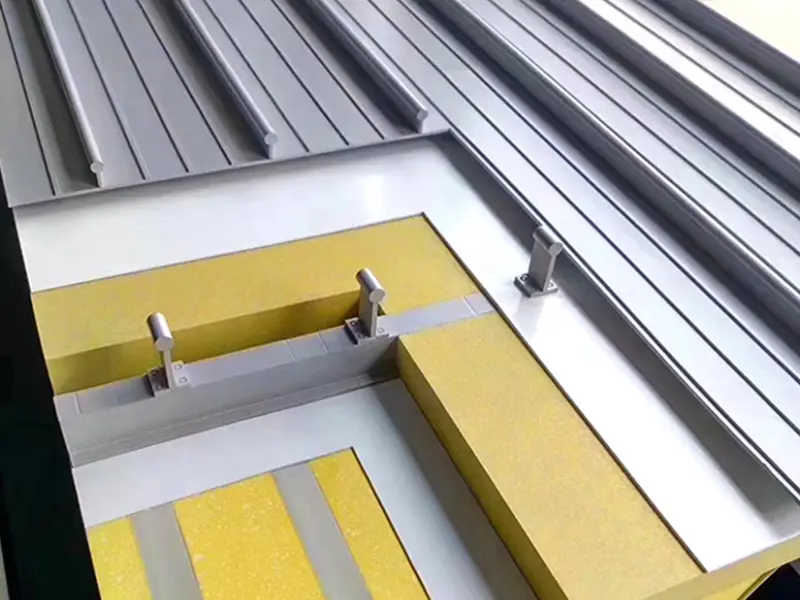

- Standing seam aluminium sheet: Modern design, watertight, long-lasting.

- Color-coated roofing sheet: Available in multiple colors for aesthetic projects.

- Embossed roofing sheet: Extra strength and scratch-resistant surface.

Aluminium Roofing Sheet Design

The design of aluminium roofing sheets varies according to architectural needs:

- Wave-shaped corrugated panels for classic roofs

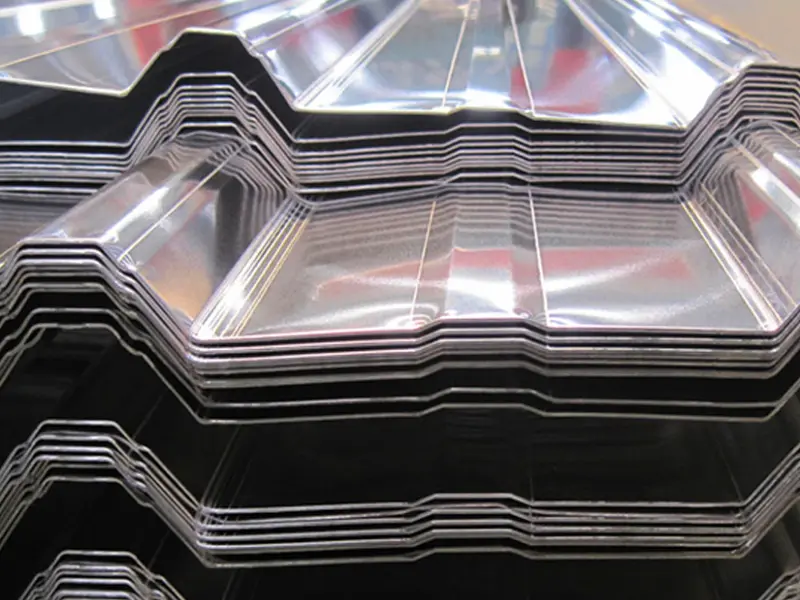

- Trapezoidal profiles for strong load-bearing roofs

- Tile pattern sheets for decorative applications

- Seamless panels for modern buildings

Aluminium Roofing Sheet Design & Best Types

The aluminium roofing sheet design is not just about aesthetics; it also affects performance. When looking for the Best Types Of Aluminium Roofing Sheets, consider the following:

- Corrugated Sheets: Cost-effective, easy to install, and classic. Best for budget-friendly projects.

- Trapezoidal Sheets: Offer superior strength and better water run-off, making them ideal for larger commercial or industrial buildings.

- Standing Seam Panels: The premium choice for modern architecture. Their concealed fasteners provide a sleek look and exceptional weatherproofing, ensuring a long lifespan.

- Pre-painted Aluminium Sheets: Available in a wide range of colors and finishes, offering aesthetic flexibility and additional protection against UV rays and weathering. These often use high-quality paint systems like PVDF or SMP.

How to Choose Aluminium Roofing Sheets

Selecting the best aluminium roofing sheet involves considering several factors to ensure it meets your project’s specific needs and budget.

- Project Type: Residential, commercial, industrial, or agricultural? This will guide your choice of profile and thickness.

- Local Climate: Consider factors like heavy rainfall, snow load, high winds, or coastal salt spray. This influences the required alloy, thickness, and profile.

- Budget: While aluminium might have a higher upfront cost than some materials, its longevity and low maintenance often result in lower lifetime costs.

- Aesthetics: The profile, color, and finish should complement the building’s design.

- Manufacturer Reputation: Choose a reputable factory or supplier known for quality and service.

- Warranty: Always check the warranty offered on the sheets and their finish.

Aluminium Roofing Sheets & Panels: Our Factory Advantage

As a leading factory for aluminium roofing sheets & panels, we specialize in producing high-quality materials designed for longevity and performance. Our state-of-the-art manufacturing processes ensure:

- Precision Rolling: Consistent thickness and profile accuracy.

- Quality Alloys: Only premium 3000 and 5000 series alloys are used.

- Customization: We can produce sheets to specific lengths, widths, and profiles to minimize waste and suit unique designs.

- Direct Supply: Buying directly from the factory ensures competitive pricing and reliable quality control for your aluminium roofing sheet needs.

Why Choose Aluminium for Your Roof?

Aluminium has become a top material for roofing, offering many advantages over traditional options. It’s a smart investment for both residential and commercial projects.

- Exceptional Durability: Aluminium does not rust or corrode, making it incredibly long-lasting, even in harsh weather conditions.

- Lightweight: It puts less stress on the building structure, which can reduce construction costs.

- Energy Efficient: Aluminium reflects sunlight, keeping buildings cooler in hot climates and potentially reducing air conditioning costs.

- Low Maintenance: Requires very little upkeep once installed.

- Environmentally Friendly: It is 100% recyclable, making it a sustainable choice.

- Versatile Design: Available in many profiles and colors to match any architectural style.

Packaging for Safe Delivery

Aluminium roofing sheets are packaged carefully to ensure safe delivery:

- Bundled with steel straps

- Plastic wrapping for moisture protection

- Wooden pallets for export shipping

FAQ: Your Questions Answered About Aluminium Roofing Sheets

Q1: Which company’s roofing sheet is best?

A1: The “best” company often depends on specific product lines and customer service in your region. Look for a factory or supplier with a strong reputation for using high-grade aluminium alloys, consistent quality control, comprehensive warranties, and good customer reviews. Our commitment as a specialized manufacturer is to provide the best aluminium roofing sheet quality directly to you.

Q2: Is aluminium sheet good for roofing?

A2: Absolutely! Aluminium sheet is an excellent choice for roofing. It’s incredibly durable, resistant to rust and corrosion, lightweight, energy-efficient, and fully recyclable. These properties make it one of the best types of aluminium roofing sheets for long-term performance and sustainability.

Q3: Which roofing sheet lasts longer?

A3: Among common roofing materials, a high-quality aluminium roofing sheet is among the longest-lasting options. With proper installation and maintenance, aluminium roofs can easily last 50 years or more, often outperforming many other materials like asphalt shingles or even some steel variants due to its superior corrosion resistance.

Q4: Which thickness roofing sheet is best?

A4: The best thickness roofing sheet depends on your project’s specific requirements, such as roof span, local wind loads, and expected snow loads. For most residential applications, a thickness between 0.5mm and 0.7mm (26-24 gauge) is usually sufficient. For industrial or heavy-duty use, thicker sheets (0.7mm to 1.0mm or more) might be required for enhanced strength and durability. Refer to our thickness table above for guidance.