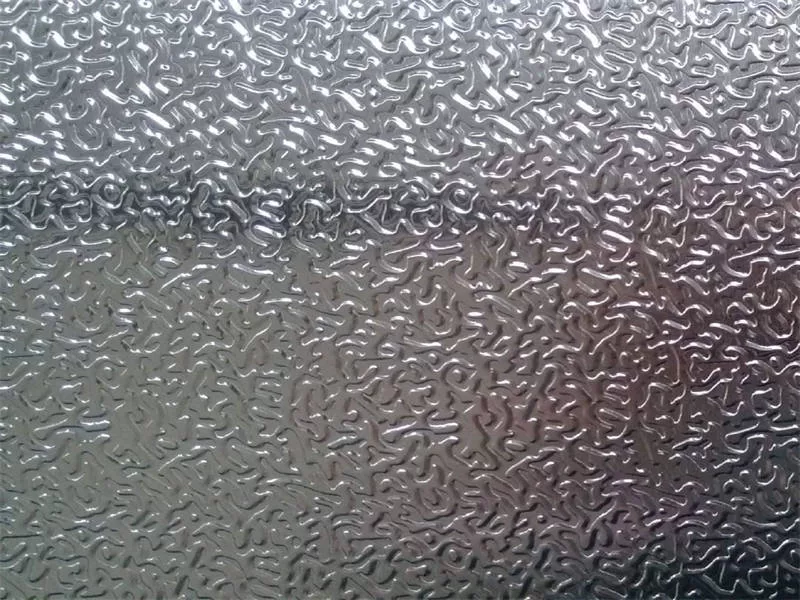

Are you looking for a versatile and durable metal solution? Aluminum stucco embossed sheet is an excellent choice for a wide range of applications. These unique aluminum sheets offer both functional benefits and an appealing aesthetic.

Specifications: Aluminum Stucco Embossed Sheet

Here’s a table outlining common specifications for aluminum stucco embossed sheets:

| Specification Category | Description / Common Values |

|---|---|

| Classification | Aluminum Stucco Embossed Sheet, Aluminum Coil, Aluminum Plate |

| Thickness | 0.4 mm – 3.2 mm (0.016 inches – 0.125 inches) Common: 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm |

| Alloy | 1050, 1060, 1100, 3003, 3004, 3005, 5005, 5052 (Each alloy offers different properties like corrosion resistance, formability, and strength) |

| Temper | O (Annealed), H12, H14, H16, H18, H22, H24, H26, H32 (Determines hardness and ductility) |

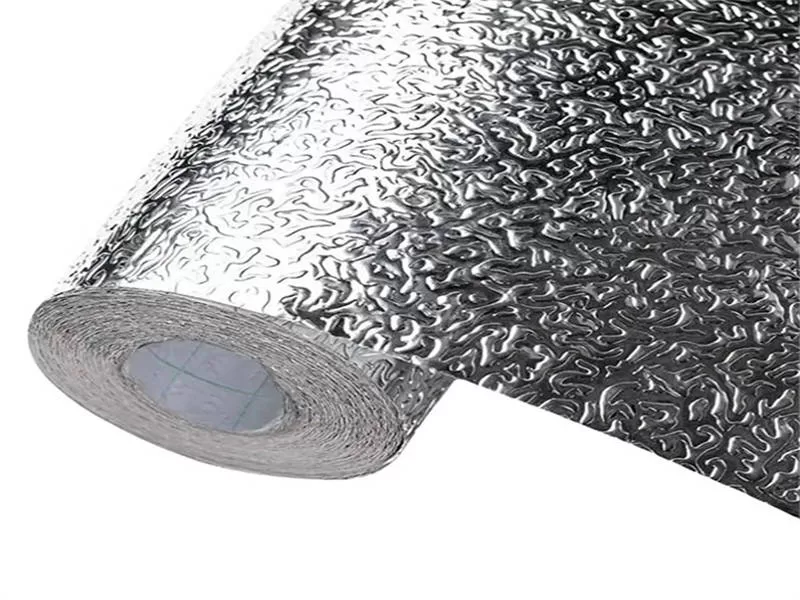

| Width | Commonly 1000mm, 1200mm, 1220mm, 1250mm, 1500mm (Custom widths available) |

| Length | Coil (Continuous), or Cut-to-length sheets (e.g., 2000mm, 2440mm, 2500mm, 3000mm, 6000mm) |

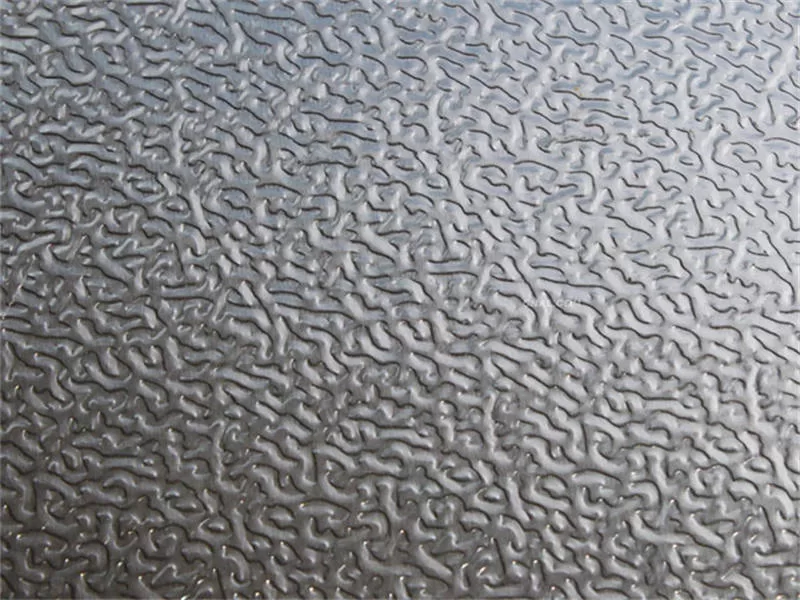

| Surface Finish | Stucco Embossed (one side or both sides) |

| Packaging | Standard export wooden pallets, seaworthy wooden cases, or coils with paper interleaving and protective film. Secure strapping to prevent damage during transit. |

Advantages of Using Stucco Embossed Aluminum Sheets

Aluminum stucco embossed sheets offer several distinct advantages:

- Enhanced Aesthetics: The unique stucco pattern provides an attractive finish that can hide minor imperfections and add a premium look.

- Reduced Glare: The textured surface diffuses light, significantly reducing glare and reflections, which is beneficial in brightly lit environments.

- Increased Rigidity and Strength: The embossing process stiffens the aluminum sheet, making it more resistant to bending and warping compared to a flat sheet of the same thickness.

- Improved Grip (Anti-Slip): While not a primary anti-slip material like diamond plate, the textured surface can offer a slight improvement in grip, making it safer for certain applications.

- Corrosion Resistance: As with all aluminum products, stucco embossed aluminum inherits aluminum’s natural resistance to rust and corrosion, making it suitable for both indoor and outdoor use.

- Lightweight: Aluminum is inherently lightweight, which simplifies transportation, handling, and installation, and reduces structural load.

- Durability: These sheets are very durable and can withstand significant wear and tear, ensuring a long lifespan.

- Easy to Clean: The surface is relatively easy to clean and maintain.

Application Areas for Aluminum Stucco Embossed Sheet

The versatility of aluminum stucco embossed sheet makes it ideal for numerous applications across various industries. Its combination of aesthetic appeal and functional benefits makes it a popular choice.

- Refrigeration and HVAC:

- Interior linings for refrigerators, freezers, and cold storage rooms.

- Ductwork and insulation jacketing in heating, ventilation, and air conditioning systems.

- Building and Construction:

- Decorative wall panels and ceiling tiles.

- Architectural cladding and fascias.

- Trailer and RV siding.

- Insulation barriers and vapor retarders.

- Transportation:

- Interior and exterior panels for buses, trains, and recreational vehicles.

- Toolbox construction.

- Industrial Uses:

- Equipment covers and protective casings.

- Work surfaces and workbench tops.

- Soundproofing panels.

- Consumer Goods:

- Appliance backings and interiors.

- Decorative elements in furniture.

Why Choose Stucco Embossed Aluminum for Your Next Project?

When considering a material for your next project, aluminum stucco embossed sheet offers an unbeatable combination of beauty, strength, and functionality. Its unique texture, lightweight nature, and excellent corrosion resistance make it a smart investment for applications ranging from industrial insulation to decorative architectural features. By choosing stucco embossed aluminum, you are opting for a reliable, durable, and aesthetically pleasing solution that stands the test of time.

Consider the distinct advantages and wide range of uses that aluminum stucco embossed sheets provide. Whether you need a material for insulation, a decorative finish, or a durable protective layer, these sheets offer a robust and attractive option.

FAQ

What is Stucco Embossed Aluminum?

Stucco embossed aluminum refers to an aluminum sheet that has been mechanically textured to create a distinct, non-directional pattern. This pattern resembles the finish of traditional stucco, giving it a unique visual appeal. The embossing process not only adds to the aesthetic but also enhances the sheet’s properties.

What is a Stucco Aluminium Sheet?

A stucco aluminum sheet is a flat-rolled aluminum product with a uniformly textured surface pattern. These sheets are commonly used for:

Signage and decorative elements

Building facades and cladding

Interior wall panels

Ceiling systems

Elevator interiors

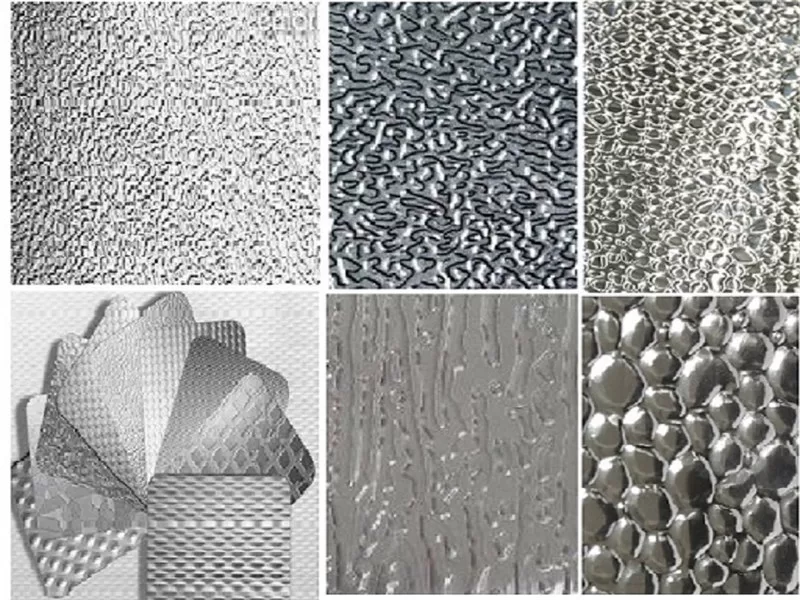

What is Embossed Aluminium?

Embossed aluminum refers to aluminum sheets with raised or indented patterns. The stucco pattern is one of the most popular designs, but other types include:

- Diamond embossed

- Leather grain embossed

- Checkered plate

Benefits of Embossed Aluminum

Improved Grip – Reduces slipping in flooring applications.

Enhanced Aesthetics – Adds visual appeal to surfaces.

Better Durability – The texture helps hide scratches and wear.

How Thick is a Stucco Aluminium Sheet?

Stucco embossed aluminum sheets come in various thicknesses depending on their use:

| Application | Recommended Thickness |

|---|---|

| Decorative Wall Panels | 0.5mm – 1.5mm |

| Roofing & Cladding | 1.5mm – 3mm |

| Industrial Flooring | 3mm – 6mm |

Thicker sheets (above 3mm) are used for heavy-duty applications, while thinner sheets are suitable for lightweight designs.

Why Choose Stucco Embossed Aluminum?

Stucco embossed aluminum is a top choice for many industries because:

- Weather-resistant – Performs well in harsh climates.

- Cost-effective – Cheaper than real stucco with longer lifespan.

- Versatile – Can be painted or coated for custom looks.

Key Industries Using Stucco Embossed Aluminum

Construction – Siding, roofing, and partitions.

Marine – Boat interiors and dock components.

Automotive – Truck body panels and RV exteriors.

Interior Design – Feature walls and decorative panels.

Technical Specifications

| Parameter | Typical Value |

|---|---|

| Tensile Strength | 100-310 MPa |

| Elongation | 10-25% |

| Surface Hardness | 60-90 HB |

| Temperature Resistance | -50°C to 150°C |

Installation Guidelines

- Surface Preparation: Clean substrate

- Cutting: Use fine-tooth blades

- Fastening: Appropriate rivets or clips

- Joint Treatment: Matching sealants

- Cleaning: Post-installation wipe down

Cost Considerations

| Factor | Price Impact |

|---|---|

| Alloy type | +15-25% for 5000/6000 series |

| Thickness | +10% per 0.5mm increase |

| Color finish | +20-35% for custom colors |

| Order quantity | Volume discounts available |

Maintenance Recommendations

- Regular Cleaning: Every 6-12 months

- Method: Soft brush with mild detergent

- Avoid: Abrasive pads or acidic cleaners

- Inspection: Check fasteners annually

Industry Trends

- Eco-Friendly: Increased recycled content

- Digital Embossing: Precise pattern control

- Composite Panels: Aluminum stucco with insulation

- Antimicrobial: Copper-infused surfaces