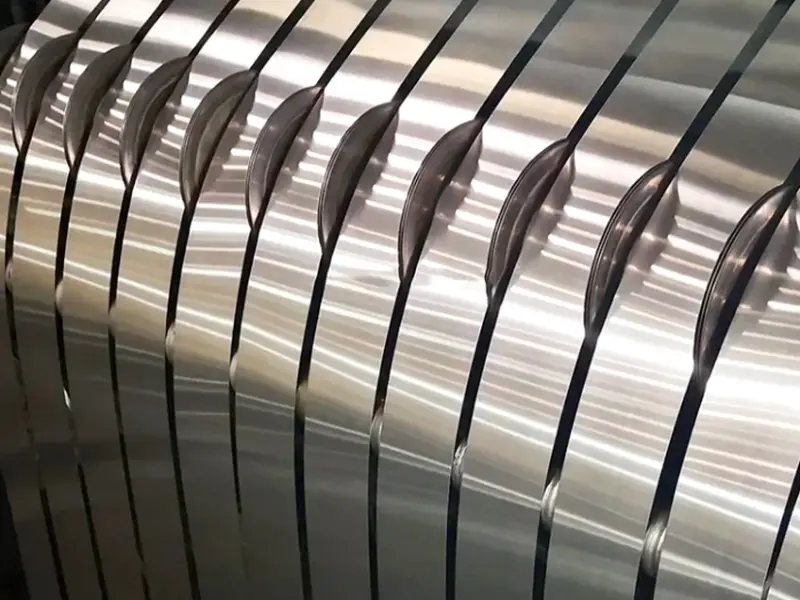

— Worthwill Aluminum Factory

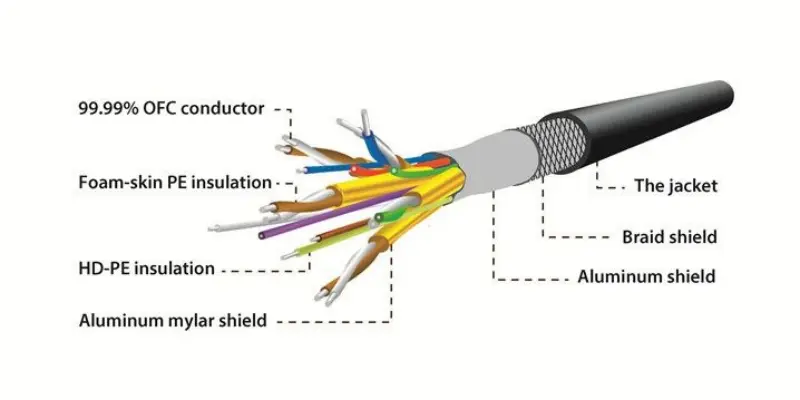

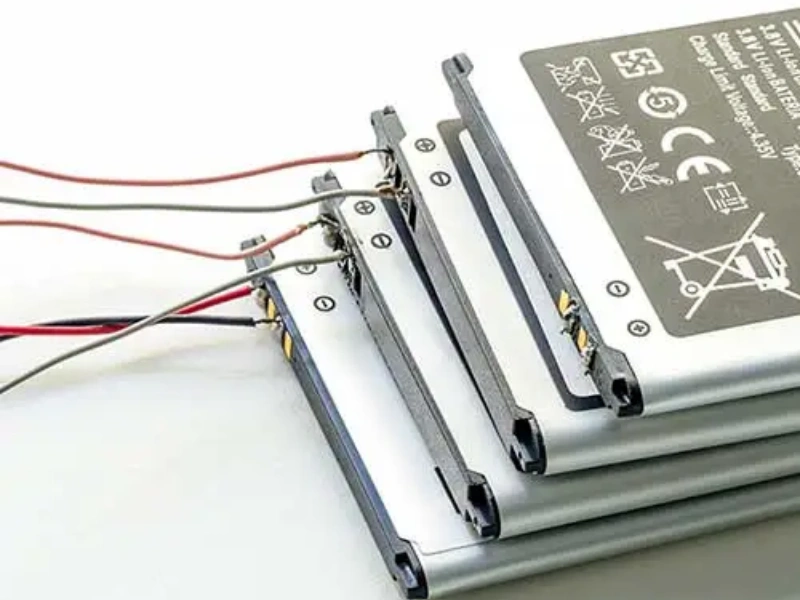

Worthwill Aluminum provides Aluminum Strip and Foil for Cable and data cables, ensuring stable performance and long service life. Aluminum is a key material used in the electrical and communication cable industry.

Its advantages include excellent electrical conductivity, lightweight, flexibility, and corrosion resistance.

Aluminum Strip for Power Cable

Aluminum strip is commonly used as a wrapping and shielding layer in power cables.

It protects the cable core from moisture, corrosion, and electromagnetic interference.

| Product | Alloy | Thickness (mm) | Width (mm) | Application |

|---|---|---|---|---|

| Aluminum Strip for Power Cable | 1060, 1100, 3003, 5052 | 0.10–3.00 | 20–800 | Wrapping layer for power and control cables |

| Coated Aluminum Strip | 8011 + PE/PVC | 0.10–0.50 | 50–600 | Insulation and moisture-proof layer |

| Aluminum Tape for Cable | 1060, 3003 | 0.15–0.25 | 30–500 | Shielding and connection layer |

These strips are soft, easy to form, and can be supplied with film coating or adhesive according to the customer’s design.

Aluminum Foil for Communication Cable

Aluminum foil is an ideal material for shielding signal cables, reducing signal loss and preventing electromagnetic interference (EMI).

| Product | Alloy | Thickness (mm) | Width (mm) | Use |

|---|---|---|---|---|

| Aluminum Foil for Cable Shielding | 8011, 1235 | 0.006–0.05 | 50–600 | Data and signal cable shielding |

| Laminated Aluminum Foil | 8011 + PET/PE | 0.01–0.05 | 50–600 | Telephone and network cable |

| Bonded Aluminum Foil | 1145, 1235 | 0.008–0.04 | 60–800 | Audio, video, coaxial cable shielding |

Worthwill Aluminum uses precise rolling and lamination to ensure uniform thickness, high adhesion strength, and excellent surface quality.

Advantages of Aluminum Cable Material

- High conductivity: 60–62% IACS

- Lightweight: Only 1/3 the weight of copper

- Corrosion resistant: Naturally forms a protective oxide layer

- Good thermal conductivity: Ideal for heat dissipation

- Recyclable and eco-friendly: 100% recyclable without performance loss

These advantages make aluminum strips and foils a cost-effective alternative to copper in modern cable manufacturing.

Common Alloys and Tempers

| Alloy | Temper | Features | Typical Use |

|---|---|---|---|

| 1060 | O / H14 / H18 | High purity, good conductivity | Power cable strip |

| 1100 | O / H16 | Excellent corrosion resistance | Shielding foil |

| 3003 | H24 | Better strength and formability | Coated aluminum strip |

| 5052 | H32 / H34 | High strength and corrosion resistance | Heavy-duty cable jacket |

| 8011 | O | Soft, suitable for lamination | Foil for data cable |

| 1235 | O | High flexibility | Shielding foil for communication cables |

Manufacturing Process at Worthwill Aluminum

- Raw Material Casting → Using high-purity aluminum ingots

- Hot Rolling & Cold Rolling → Controlled thickness and surface finish

- Annealing → Adjusting hardness and ductility

- Surface Treatment → Degreasing, coating, or lamination

- Slitting & Packaging → Custom sizes with moisture-proof packaging

Worthwill Aluminum ensures stable conductivity, tight tolerance (±0.01 mm), and smooth edges for all cable-grade strips and foils.

Applications of Aluminum for Cable

- Power transmission and distribution cables

- Control and instrumentation cables

- Communication and telephone cables

- Audio and video cables

- Coaxial cables

- Network and data transmission cables

These aluminum materials have wide applications in both industrial and residential electrical systems, offering long-lasting protection and efficient performance.

Why Choose Worthwill Aluminum

- Factory direct supply with stable quality and fast delivery

- Custom thickness, width, and coating available

- International export experience to Europe, South America, and Asia

- Strict quality control under ISO standards

Worthwill Aluminum is committed to providing durable, high-conductivity, and cost-effective aluminum materials for the global cable industry.

Aluminum Strip and Foil for Cable

Aluminum strip and foil are essential components in the power and communication cable industry.

With advanced rolling equipment and rich experience, Worthwill Aluminum offers complete cable aluminum solutions that meet international standards for conductivity, strength, and protection.

If you need aluminum strips or foils for cable, contact Worthwill Aluminum for reliable factory prices and fast technical support.