Aluminum Sheet

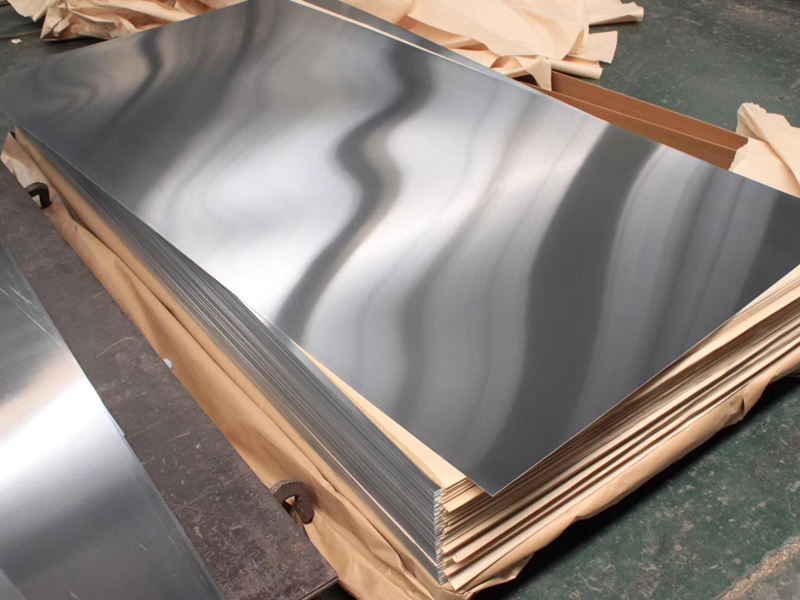

Aluminum sheet is an aluminum product which rolled and processed from aluminum ingots. Whether light-duty or heavy-duty, they have an excellent strength-to-weight ratio and natural corrosion resistance. Aluminium sheet/plate has a wide range of use. It’s very suitable for applications in aerospace, aircraft manufacturing, beverage packaging, cryogenic storage applications, siding, gutters and roofs. It also refers to rectangular aluminum plate.

| Item | Aluminum Sheet |

| Alloy | 1, 3, 5, 6, 7, 8 series |

| Temper | Q-H112 |

| Thickness | 0.2-6mm |

| Width | 200-2650mm |

| Length | 500-16000mm |

| Application | Power battery shell, mobile phone shell, etc. |

| MQQ | 2-4 tons |

Applications

- Lighting

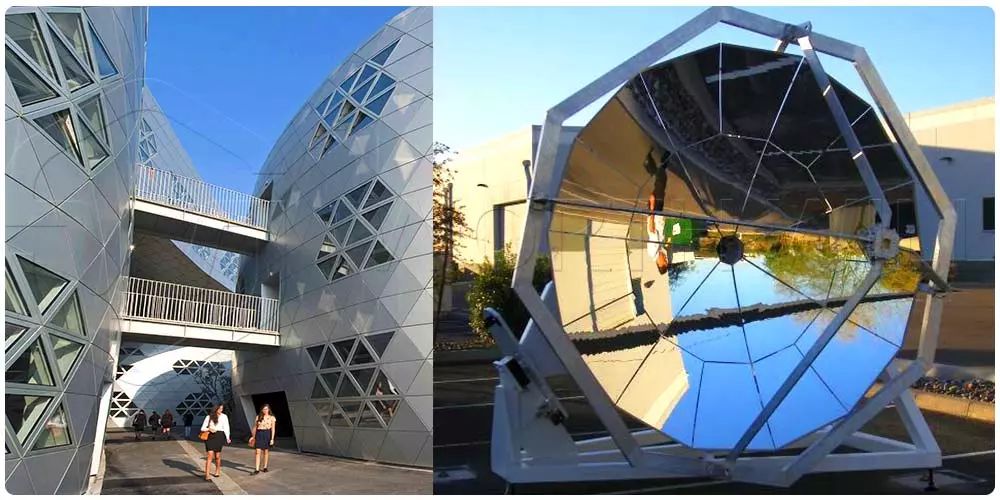

- Solar reflector

- Building appearance

- Interior decoration: ceiling, wall, etc.

- Furniture, cabinets

- Elevator

- Signs, nameplates, bags

- Car interior and exterior decoration

- Interior decorations: such as picture frames

- Household appliances: refrigerators, microwave ovens, audio equipment, etc.

Advantages

- Corrosion resistant

- Anti rust

- High strength

- Superior rigid

- Good ductility

- Recyclable

- Eco-friendly

Types

1. By Alloy Series

| Alloy | Key Properties | Common Uses |

|---|---|---|

| 1xxx (1050, 1100) | ≥99% pure Al, excellent corrosion resistance | Food packaging, chemical tanks |

| 3xxx (3003, 3004) | Manganese-added, moderate strength | Gutters, roofing, signage |

| 5xxx (5052, 5083) | Magnesium-added, marine-grade | Boat hulls, offshore platforms |

| 6xxx (6061, 6063) | Heat-treatable, strong | Structural frames, automotive parts |

| 7xxx (7075) | Zinc-added, aerospace strength | Aircraft components |

2. By Thickness

| Category | Thickness Range | Typical Applications |

|---|---|---|

| Foil | 0.006–0.2 mm | Packaging, insulation |

| Thin Sheet | 0.2–6.0 mm | Automotive panels, electronics |

| Plate | >6.0 mm | Shipbuilding, military armor |

3. By Surface Finish

A. Mill Finish

Natural uncoated surface

Used for industrial applications (e.g., machinery parts)

B. Coated Finishes

| Type | Description | Advantages |

|---|---|---|

| Anodized | Electrochemical oxide layer | Scratch-resistant, colors available |

| PVDF Painted | Polyvinylidene fluoride coating | UV-resistant for architecture |

| Embossed | Textured patterns (diamond/stucco) | Anti-slip flooring |

C. Specialty Finishes

Brushed: Decorative appeal (appliances)

Mirror Polished: Reflective surfaces (lighting)

4. By Temper (Hardness)

| Temper | Description | Example Uses |

|---|---|---|

| O (Annealed) | Soft, formable | Deep-drawn cookware |

| H12/H14 | Work-hardened | HVAC ducts |

| T6 | Solution heat-treated | Structural components |

5. Specialty Aluminum Sheets

Perforated Sheets: Filtration, architectural screens

Composite Panels (Alucobond): Aluminum skin + PE core for cladding

Tread Plate: Diamond pattern for walkways

Other Special Sheets

According to the surface treatment, we divide aluminum sheets from our company into four types.

- Brushed aluminum: Brushed aluminium have an unique finish. By mechanical sanding, brushed aluminum appears soft and distinctive fine lines patterns. As a building decoration material. Typically, it’s suitable for indoor signage, though is equally weather resistant.

- Polish aluminum: In order to make the surface like a mirror. The production process of coated mirror aluminum includes rolling and polishing. The sheet has high light reflectivity. There are many kinds of color in the mirror finish aluminum such as gold, gold tea etc.

- Checkered aluminum plate: Aluminum checkered plate is a high-cost modern material. It’s widely used in furniture, such as air conditioners, refrigerators, carriages, platforms, decorative strips etc.

- Embossed aluminium: Embossed aluminum is a type of aluminum product which appears sheet or coil shape. We also call it stucco embossed sheet or coil. It’s a kind of aluminum product which form a variety of decorative pattern on the surface after rolling process on the basis.

Packing

Firstly, paper of film the aluminum plate to ensure that the surface of the aluminum plate is intact and free of scratches. Secondly, export standard wooden boxes and brackets for packaging. At last, we can also packing according to customer other packaging requirements.

Aluminum sheet vs aluminum plate

Although these two products have different names, they are essentially the same. The only difference between them is the thickness. This distinction allows alu sheet to be used for lighter-duty applications, while aluminum plate is reserved for heavier-duty applications that require a thicker cut.

3003 aluminum sheet

3003 aluminum sheet is a very hot aluminum product. The alloy contains Mn as its major alloying element. 3003 aluminium is an alloy with very good corrosion resistance and moderate. It’s not heat treatable and develops strengthening from cold working only. It also has good machine-ability and welding. 3003 sheet alloy commonly used in chemical equipment, pipeline system and in general sheet metal work.

Aluminum sheets for sale

WORTHWILL is a foreign trade company which professional in producing aluminium sheet. We not only do foreign markets, but also domestic markets. In general, we have some regular aluminium sheets in stock.

In any case, as an exporter selling aluminum sheets, we must guarantee the quality of our products. Satisfy customers at the same time.

Aluminum sheet prices

Many factors can affect the price of aluminium sheet, such as raw materials, sea freight and so on. We suggest that if you want to know more exact prices, you can contact our sales staff. In addition, we have own factory, which can provide you the most competitive price under the premise of ensuring product quality.

Aluminum sheet supplier

Established in 2014, our factory has rich experience. We are a foreign trade company which specializing in the production and supply of aluminum products. Aluminum products include aluminium sheets, aluminum coils, aluminum circles and so on. Our foreign customers are very satisfied with our products. As an emerging foreign trade company, we are aim to provide foreign customers with high-quality products, suitable prices and comprehensive services. If you want to know more about us, welcome to consult us.

How To Choose Aluminum Sheet for Your Projects?

- Strength Needs:

- 5052 for marine environments

- 6061-T6 for high-stress structures

- Corrosion Resistance:

- 5xxx > 6xxx > 1xxx > 3xxx in saltwater

- Cost Efficiency:

- 3003 is budget-friendly for roofing

- 7075 is premium for aerospace

Our advantage

- Provide free samples for your reference

- Reply to your message within 12 hours

- Professionals answer your questions

- Passionate business team

- Perfect after-sales service system

- Support OEM and ODM

FAQ

Q: What’s the best alloy for outdoor use?

A: 5052-H32 – balances strength and corrosion resistance.

Q: Can aluminum sheets be welded?

A: Yes, but alloys matter:

Easy to weld: 1xxx, 3xxx, 5xxx

Require expertise: 6xxx, 7xxx

Q: How does 6061 compare to 3003?

A:

| Property | 6061 | 3003 |

|---|---|---|

| Strength | High | Medium |

| Corrosion Resistance | Good | Better |

| Cost | Higher | Lower |

Q: What’s the minimum bending radius?

A: Typically 1x sheet thickness for 90° bends (e.g., 1mm sheet = 1mm radius).

FAQ

How much does a sheet of aluminum cost?

Where to buy aluminium sheets?

Where can I buy aluminium sheets?

What is the difference between aluminum plate and alu sheet?

What is sheet aluminum used for?

How to buy aluminum?