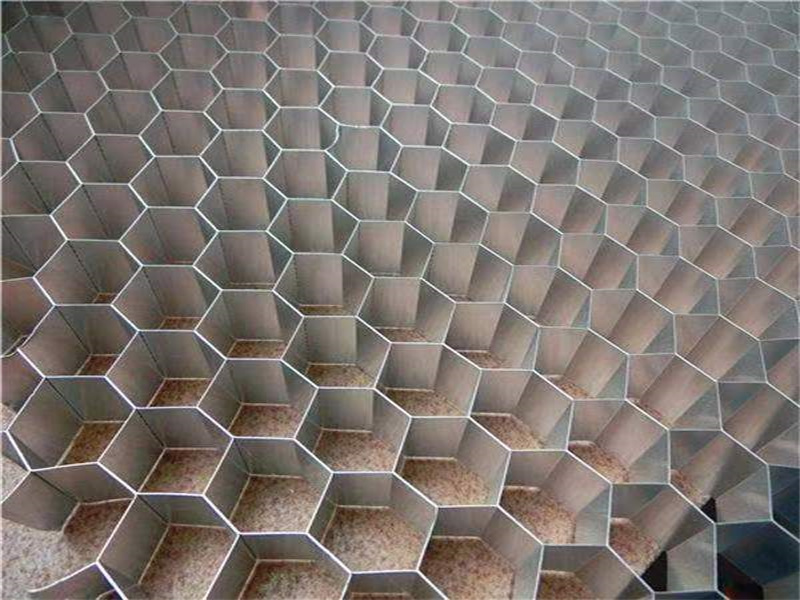

Aluminum is one of the most versatile materials used across industries due to its lightweight, corrosion resistance, and recyclability. From architecture to automotive manufacturing, aluminum products come in various forms such as coated aluminum, sheets, coils, foils, and plates, jaceting, honeycomb panels, sublimation sheets, wall panels, each designed for specific applications.

The most common aluminum product applications, including specifications, alloy types, and product classifications.

Specifications Table:

| Specification | Description |

|---|---|

| Classification | Sheet, Coil, Foil, Plate, Bar, Extrusion |

| Thickness | 0.05 mm – 100 mm |

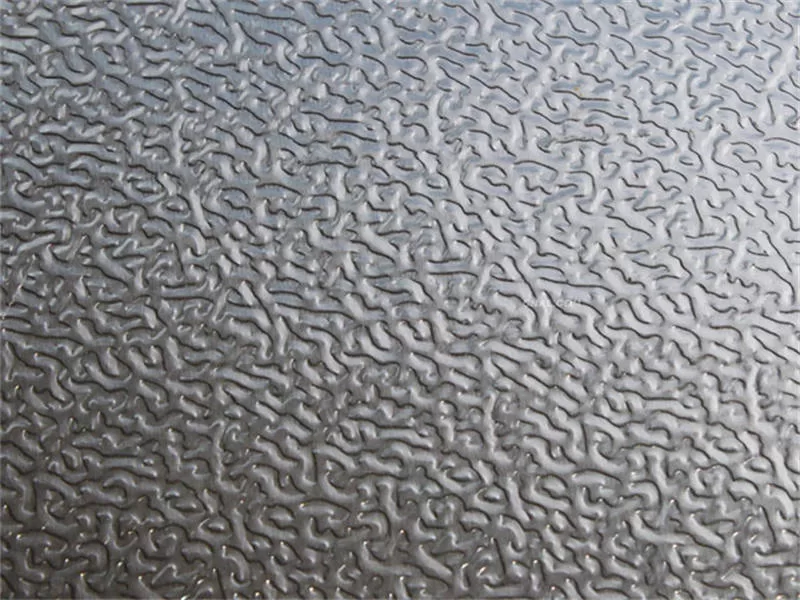

| Surface Finish | Mill Finish, Embossed, Brushed, Anodized |

| Alloy Types | 1100, 3003, 5052, 6061, 8011 |

| Packaging | Wooden pallets, waterproof wrapping, customizable packaging |

Applications:

- “Aluminum sheet used in construction wall panel”

- “Embossed aluminum coil for HVAC systems”

- “Aluminum foil for flexible food packaging”

Types of Aluminum Products:

| Product Type | Typical Alloys | Thickness Range | Application Areas |

|---|---|---|---|

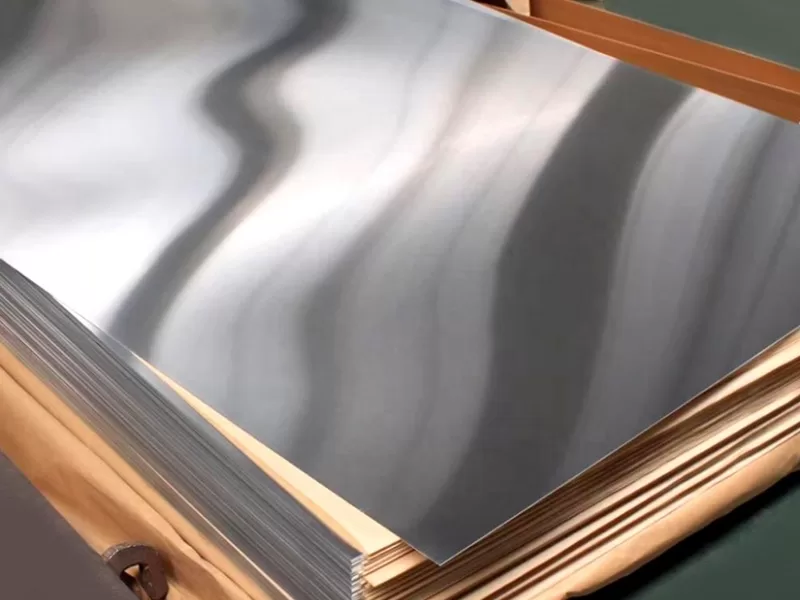

| Aluminum Sheet | 1100, 5052 | 0.2mm – 6mm | Roofing, facades, transportation |

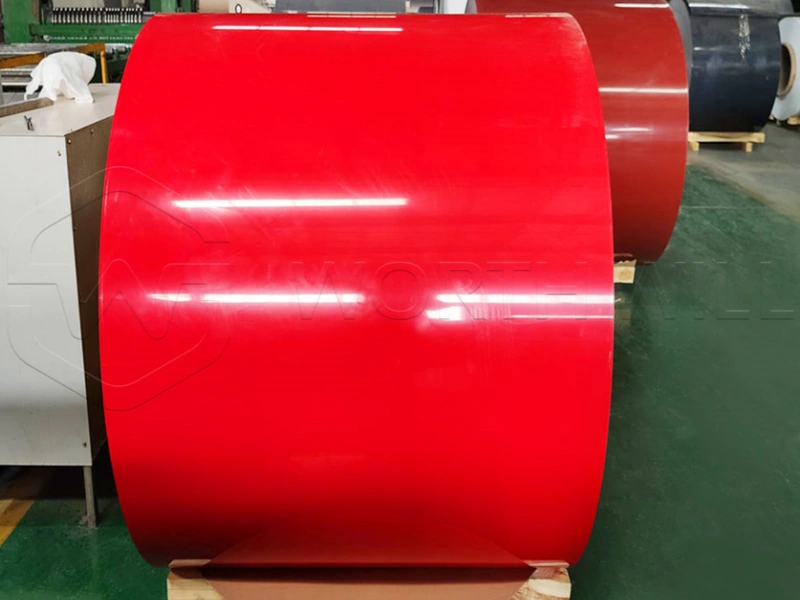

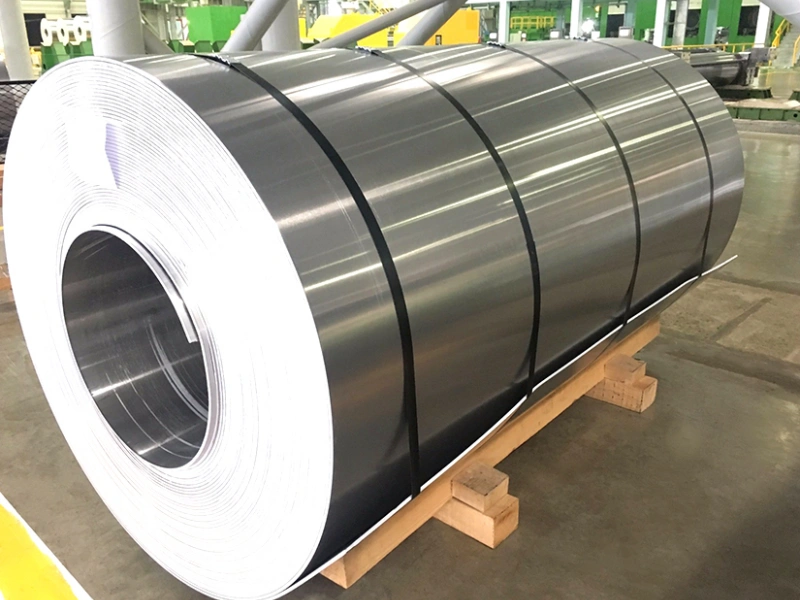

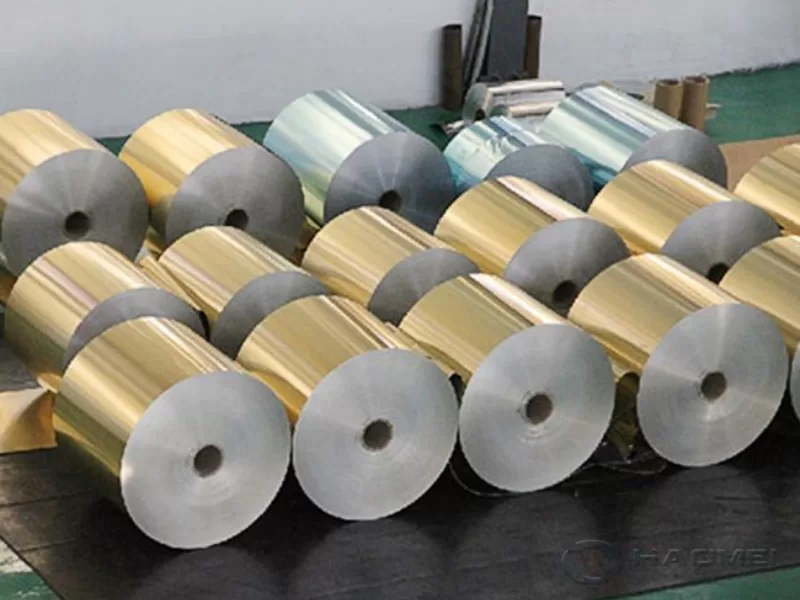

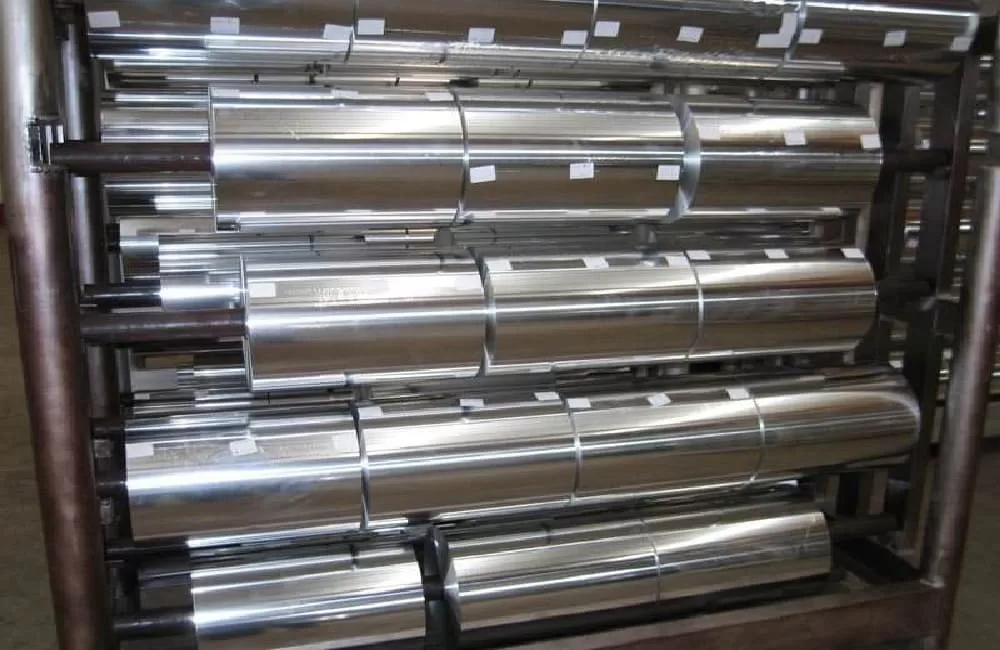

| Aluminum Coil | 3003, 8011 | 0.1mm – 3mm | Insulation, cladding, gutters |

| Aluminum Foil | 8011, 1235 | 0.006mm – 0.2mm | Packaging, household use, pharma |

| Aluminum Plate | 6061, 7075 | 6mm – 100mm | Aerospace, marine, tooling |

| Aluminum Circle/Disc | 1050, 3003 | 0.3mm – 4mm | Cookware, lighting, signage |

| Aluminum Extrusion | 6063, 6061 | Custom profiles | Windows, doors, heat sinks |

Why Aluminum Is Widely Used

Aluminum’s combination of strength and light weight makes it ideal for high-performance applications. Key advantages include:

- Corrosion resistance (great for marine and outdoor use)

- High strength-to-weight ratio

- Thermal and electrical conductivity

- Easy formability and weldability

- Recyclability (eco-friendly manufacturing)

Top Applications of Aluminum Products

1. Construction Industry

Aluminum is widely used in:

- Building facades

- Curtain walls

- Ceilings and partitions

- Windows and doors

- Roofing sheets and composite panels

2. Transportation

Aluminum’s lightweight nature reduces vehicle weight and improves fuel efficiency.

- Car bodies and panels

- Truck trailers and tanks

- Railway coaches

- Shipbuilding (marine grade plates)

3. Packaging

Aluminum foil and sheets are ideal for:

- Food containers

- Pharmaceutical blister packs

- Beverage cans

- Flexible packaging laminates

4. HVAC and Insulation

- Aluminum jacketing for ducts and pipes

- Foil-faced insulation panels

- Embossed aluminum for anti-slip and appearance

5. Electrical and Electronics

- Conductive strips and foils

- Heat sinks and casings

- Lighting reflectors and parts

6. Cookware & Household Use

- Non-stick aluminum discs and circles

- Foil rolls for kitchen and grill use

- Custom laser printable aluminum sheets

Frequently Asked Questions (FAQs)

What alloys are best for marine applications?

Marine-grade alloys like 5052 and 5083 offer excellent corrosion resistance for seawater environments.

Which aluminum product is best for roofing?

Embossed aluminum coils (3003 or 8011) are commonly used for roofing due to their formability and durability.

Can I use aluminum products for custom signage?

Yes, sublimation aluminum sheets and ACP panels are ideal for custom signs, billboards, and displays.

Packaging Options

We offer:

- Plastic wrapping + wooden pallet

- Waterproof kraft paper + corner protection

- Customized logos or labels on request

Conclusion

Aluminum products have countless applications, from construction and automotive to packaging and electronics. Choosing the right aluminum alloy, thickness, and finish is essential for maximizing performance and cost-efficiency.

For quality aluminum sheets, coils, foils, and custom applications — contact Worthwill Aluminum today!

📧 Email: jane@wwaluminum.com

📱 WhatsApp: +86 15736973771