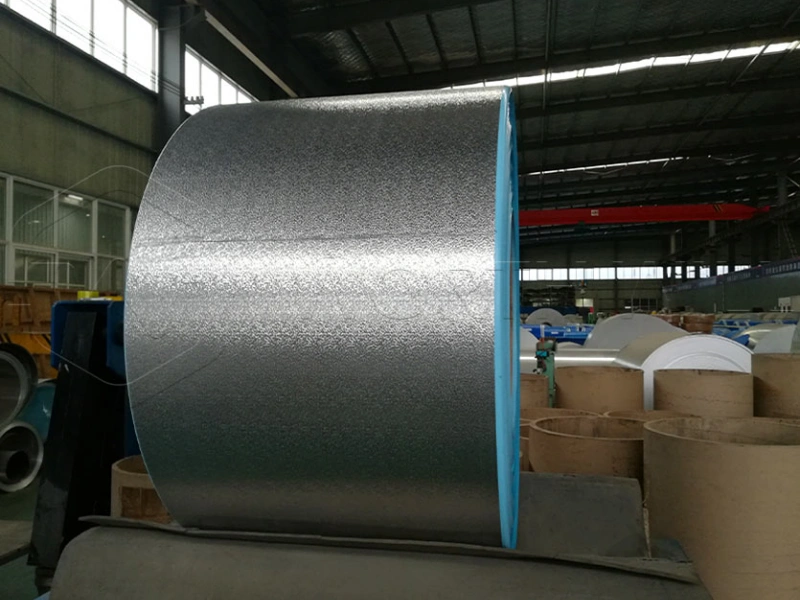

Aluminum Jacketing for Insulation and Cladding is the perfect solution for protecting thermal insulation systems on pipes, ducts, and industrial equipment. Made from high-quality aluminum alloys, this jacketing provides excellent corrosion resistance, durability, and a professional appearance.

Our products meet the highest international standards and are designed to perform in extreme environments, ensuring long-term protection.

Specification

| Product Description | Bare & Coated Aluminum Jacketing Coil |

|---|---|

| Standards | ASTM B209 / C1729 |

| Alloy | 3003, 3105, 5005, 6061, 6082 |

| Temper | H14, H16, H24 (Special tempers available on request) |

| Thickness | 0.3 mm – 1.5 mm |

| Width | 914 mm, 1000 mm, 1219 mm |

| Lengths | 100’ (30m), 200’ (60m), Jumbo Rolls, Custom lengths available |

Common Alloys: 3003 and More

Alloy 3003 is a popular choice for insulation jacketing due to its excellent formability and corrosion resistance. We also offer alloys like 3105, 5005, 6061, and 6082 for specific applications requiring different mechanical or chemical properties. Using the right aluminum alloy is key to the performance of your metal cladding.

Tempers H14 and H24: Balancing Flexibility and Strength

The H14 temper provides a good balance of flexibility and strength, making it easy to install the aluminum jacketing around pipes and fittings. The H24 temper offers increased mechanical strength. We supply these and other tempers to meet your installation and performance needs for pipe cladding.

Types of Aluminum Jacketing

- Hot Pipe Insulation Aluminum Cladding 3003 H14

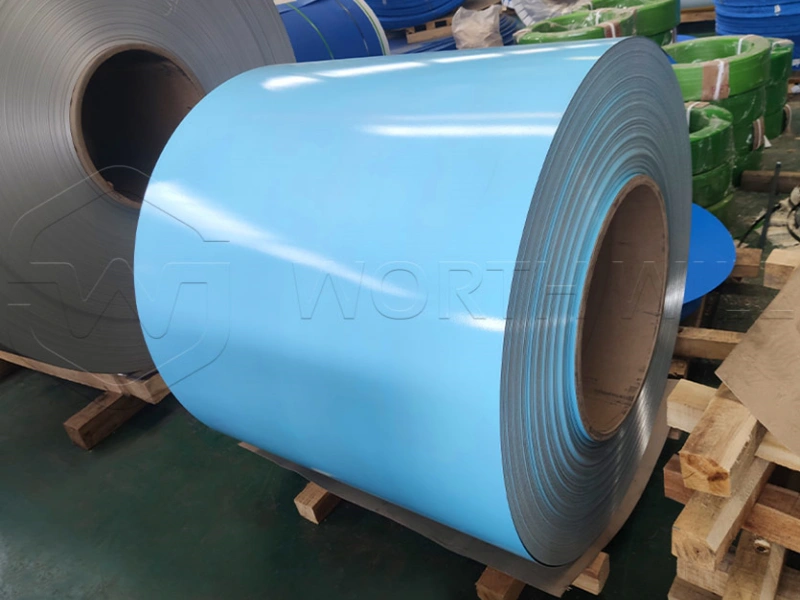

- Painted Aluminum Roll Jacketing

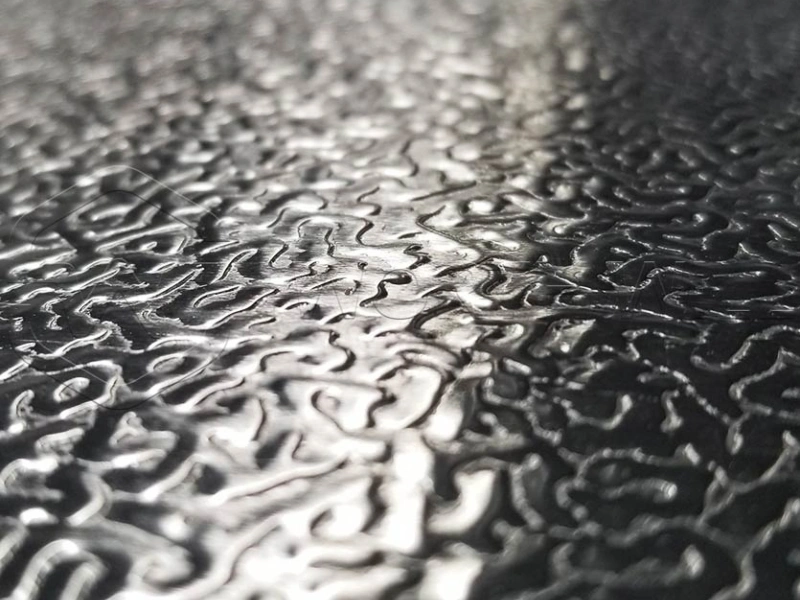

- Stucco Embossed Aluminum Jacketing Sheets and Coils

- Aluminum Jacketing for Pipe Insulation

- Aluminum Jacketing for Ductwork

Applications

Aluminum Jacketing is widely used in:

- Thermal insulation systems for industrial piping

- HVAC ductwork protection

- Equipment and tank cladding

- Petrochemical and power plants

- Marine and offshore insulation projects

Advantages of Aluminum Jacketing

- High corrosion resistance: perfect for humid and marine environments

- Lightweight: easy to handle and install

- Superior durability: long lifespan with minimal maintenance

- Professional appearance: improves the overall look of installations

- Customizable options: various thicknesses, widths, and finishes available

Packaging

All Aluminum Jacketing products are securely packed with strong wooden cases and plastic protections to prevent damage during shipping.

General Details

- Available finishes: Smooth, Stucco Embossed, Painted (White or Customized Colors)

- Accessories: Elbows, End Caps, Banding Systems

- Options: Moisture barriers for enhanced protection

Chemical Composition (Example for Alloy 3003)

| Element | Percentage |

|---|---|

| Aluminum | 96.7% |

| Manganese | 1.0% |

| Copper | 0.12% |

| Iron | 0.7% max |

(Other compositions available based on selected alloy)

Why Choose Us?

- Over 10 years of experience in aluminum manufacturing

- Production according to ASTM and ISO standards

- Strict quality control at every stage

- Factory-direct competitive prices

- Personalized service and technical support

- Fast global delivery

Related Searches

- Aluminum cladding for insulation

- Aluminum jacketing for pipes

- Painted aluminum for ductwork

- Aluminum rolls for thermal insulation

- Thermal insulation with aluminum

- Aluminum cladding coil supplier

- Aluminum Jacketing 3003 H14

FAQ

What is the best aluminum alloy for jacketing?

3003 H14 aluminum is most commonly used due to its excellent corrosion resistance and formability.

What thicknesses are available for Aluminum Jacketing?

We offer thicknesses ranging from 0.3 mm to 1.5 mm, with custom options available upon request.

Can Aluminum Jacketing be used in marine environments?

Yes, our Aluminum Jacketing is ideal for marine environments thanks to its superior corrosion resistance.

What finish is best for outdoor applications?

Stucco embossed finish is popular for outdoor use because it hides scratches and imperfections well.

Can I order customized sizes or lengths?

Yes! We can manufacture to your custom lengths and sizes in addition to standard dimensions.

Q: What alloy is best for coastal areas?

A: Alloy 3105 offers superior saltwater corrosion resistance.

Q: Can you supply custom lengths?

A: Yes, we can provide any length to meet your project requirements.

Q: What’s the lead time for orders?

A: Standard orders ship in 7-10 days; custom orders may take longer.

Q: Do you offer color matching?

A: Yes, we can match RAL colors for pre-painted products.