This is where aluminum honeycomb panel types come in. These panels are a type of sandwich composite material. This unique structure gives the panels amazing properties.

They are much lighter than solid aluminum panels of the same stiffness. From high-speed trains to sleek building facades, these panels provide a smart solution.

Specification

| Item | Description |

|---|---|

| Classification | Aluminum Honeycomb Composite Panel |

| Thickness | 6 mm – 50 mm (custom sizes available) |

| Face Skin Thickness | 0.4 mm – 1.5 mm |

| Surface Finish (Sub-label) | PVDF, PE, Anodized, Brushed, Wood Grain, Marble |

| Core Alloy | 3003, 5052 |

| Panel Alloy | 1100, 3003, 5005 |

| Standard Width | 1220 mm / 1500 mm |

| Length | Up to 6000 mm or custom cut |

Common Types of Aluminum Honeycomb Panels

Aluminum honeycomb panels come in different types based on their surface treatment and core configuration. Below are the most widely used types:

PVDF Coated Honeycomb Panel

PVDF (polyvinylidene fluoride) coating is ideal for exterior use due to its high UV resistance and weather durability.

Applications:

- Exterior wall cladding

- Curtain walls

- High-rise facades

PE Coated Honeycomb Panel

PE (polyester) coating is suitable for indoor applications. It offers good color uniformity at a lower cost.

Applications:

- Interior walls

- Ceiling panels

- Partition walls

Anodized Aluminum Honeycomb Panel

Anodized surface provides extra corrosion resistance and a metallic look. Common in public buildings and clean environments.

Applications:

- Elevator interiors

- Public transport stations

- Clean rooms

Brushed Aluminum Honeycomb Panel

This panel has a brushed finish for a modern, matte look. Often used in interior design and furniture.

Applications:

- Decorative walls

- Cabinet surfaces

- Commercial interiors

Stone/Marble Veneer Honeycomb Panel

Real stone or marble is bonded to an aluminum honeycomb base to reduce weight without sacrificing luxury appearance.

Applications:

- Hotel lobbies

- Airport counters

- Luxury retail walls

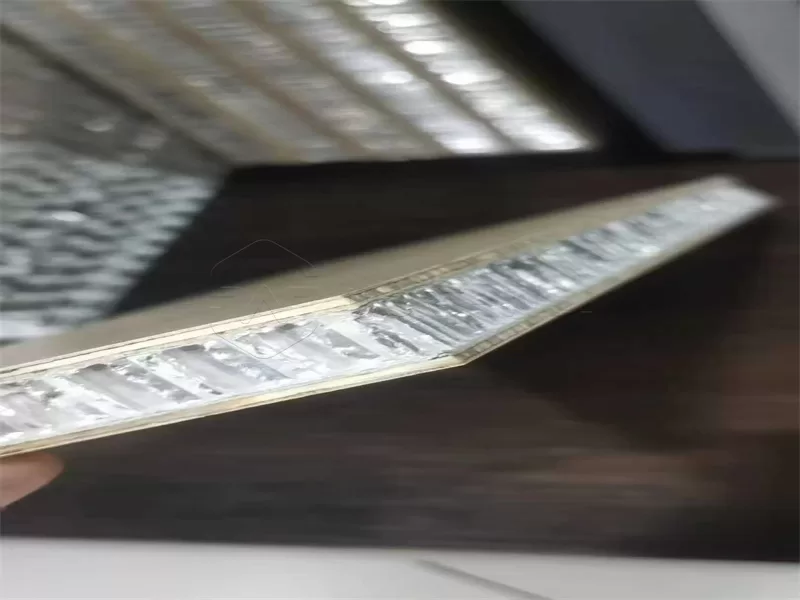

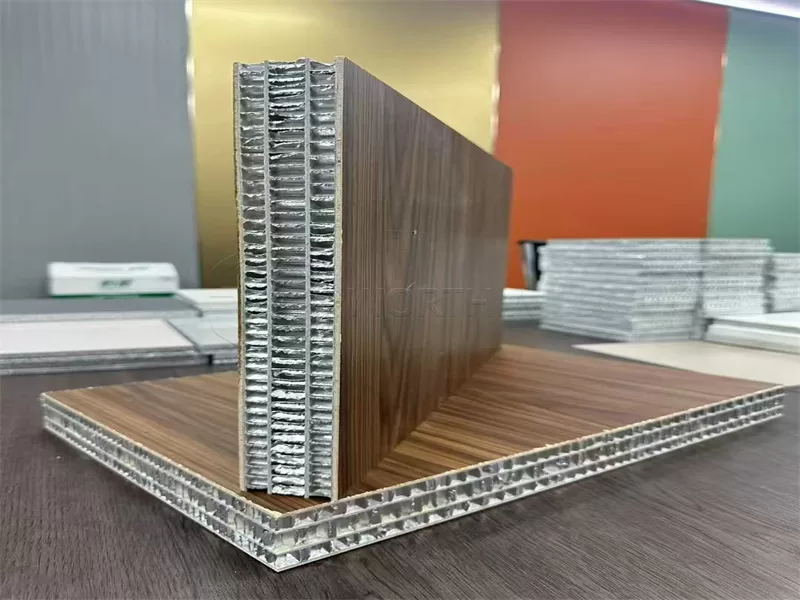

Wood Grain Aluminum Honeycomb Panel

This panel uses wood-look finishes on an aluminum surface, offering a warm aesthetic without the drawbacks of real wood.

Applications:

- Office interiors

- Conference rooms

- Hospitality design

Features and Benefits

All aluminum honeycomb panel types offer several key advantages:

- ✅ High strength-to-weight ratio

- ✅ Excellent flatness and dimensional stability

- ✅ Fire-resistant (with FR core options)

- ✅ Thermal insulation and soundproofing

- ✅ Corrosion and moisture resistance

- ✅ Easy to fabricate and install

These panels are ideal for long-term use in demanding environments.

Applications by Industry

Architecture and Construction

- • Exterior wall cladding

- • Roofing panels

- • Ceilings and partitions

- • Balcony and canopy covers

Transport and Automotive

- • Train and metro interior panels

- • Truck and trailer floors

- • Aerospace and marine partitions

- • Lightweight cargo structures

Furniture and Decoration

- • Workstations and desktops

- • Cabinet panels

- • Elevator interiors

- • Decorative cladding

Clean Rooms and Laboratories

- • Operating rooms

- • Pharmaceutical labs

- • Food processing areas

- • Data centers

Available Surface Options

We provide a variety of surface finishes to suit your design and functional needs:

| Finish Type | Features |

|---|---|

| PVDF Coated | Weather-resistant, UV protection, long-lasting color |

| PE Coated | Cost-effective, smooth gloss or matte for interiors |

| Anodized | Metallic sheen, anti-corrosion, fingerprint-resistant |

| Brushed | Elegant, modern, scratch-resistant surface |

| Wood Grain | Natural look, maintenance-free |

| Stone Veneer | Luxury appearance, lightweight alternative to real stone |

Custom finishes are also available upon request.

Why Choose Aluminum Honeycomb Panel Types?

Each type of aluminum honeycomb panel serves specific purposes and industries. Choosing the right one can help you:

- ✔ Reduce structure weight

- ✔ Improve fire safety

- ✔ Enhance appearance

- ✔ Lower long-term maintenance costs

- ✔ Speed up installation process

Our panels are designed to meet ISO, ASTM, and EN standards for performance, safety, and sustainability.

FAQs

Q: What’s the difference between PE and PVDF coated panels?

PE is suitable for interiors; PVDF is stronger and used for exteriors due to better UV resistance.

Q: Can you provide custom sizes and colors?

Yes. Panels can be customized in thickness, dimensions, color, and finish.

Q: Are aluminum honeycomb panels fireproof?

Yes, with fire-rated core materials, they meet Class A fire safety standards.

Q: Are they suitable for marine or coastal areas?

Yes, especially with anodized or PVDF finishes which resist salt spray and humidity.

Classification of Aluminum Honeycomb Panel Types

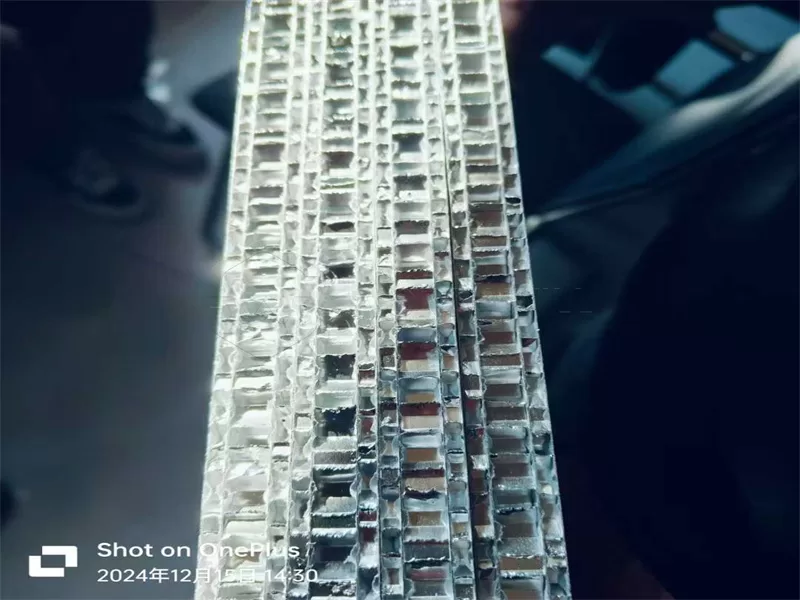

Classification by Core Structure

The heart of an aluminum honeycomb panel is its core.

- Standard Hexagonal Core: This is the most common type. The size of these hexagonal cells can vary (e.g., 6mm, 9mm, 12mm), affecting the panel’s properties. Smaller cells usually mean a stronger, more rigid panel.

- . It offers good strength and is cost-effective.

- Perforated Honeycomb Core: Some honeycomb cores have small holes (perforations) in the cell walls.

- Non-Perforated Honeycomb Core: These cores have solid cell walls, offering maximum structural integrity and preventing air or liquids from passing through.

Classification by Panel Thickness

The thickness of an aluminum honeycomb panel refers to the overall thickness of the assembled panel, including both skins and the core. This is a critical specification.

- Standard Thicknesses: Common panel thicknesses range from 6mm, 10mm, 15mm, 20mm, 25mm, to 30mm, and even up to 50mm or more for specialized applications.

- Impact on Performance: A thicker panel generally offers higher rigidity, greater spanning capabilities, and improved insulation properties. Thinner panels are lighter and more flexible. The choice of panel thickness depends directly on the structural requirements and the intended application.

Classification by Aluminum Alloy

The aluminum alloy used for both the skins and the core greatly influences the panel’s properties.

- Common Skin Alloys:

- AA3003 (3003 Series): This is a widely used aluminum alloy for the skins. It offers good strength, excellent formability, and is resistant to corrosion.

- AA5052 (5052 Series): This alloy contains magnesium, providing higher strength and superior corrosion resistance, especially in marine environments.

- Common Core Alloys:

- AA3003 (3003 Series): Also commonly used for the honeycomb core due to its good formability and strength.

- AA5052 (5052 Series): Used for cores in applications requiring higher strength and corrosion resistance.

- Properties of Alloys: Different aluminum alloy types offer varying levels of strength, flexibility, weldability, and resistance to environmental factors. Selecting the correct aluminum alloy ensures the aluminum honeycomb panel performs optimally in its intended environment.

Classification by Surface Finish

While not directly a “panel type” in terms of structure, the surface finish is crucial for the appearance and durability of aluminum honeycomb panels.

- PVDF Coating: Polyvinylidene Fluoride (PVDF) coatings are highly durable and resistant to weathering, UV radiation, and chemicals. This is a popular finish for exterior architectural applications, ensuring long-lasting color and gloss.

- PE Coating: Polyester (PE) coatings are more economical and suitable for interior applications where less extreme weather exposure is expected.

- Anodized Finish: Anodizing creates a protective oxide layer on the aluminum surface, enhancing corrosion resistance and allowing for various colors.

- Powder Coating: This finish provides a tough, durable, and often textured surface, available in a wide range of colors.

- Brushed/Mirror Finish: These are aesthetic finishes that highlight the natural look of aluminum.

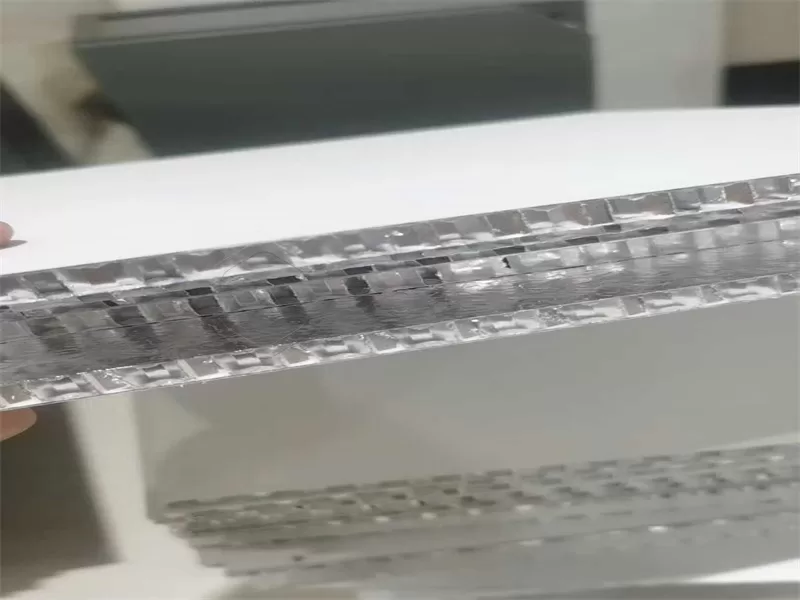

Manufacturing Process

The production of aluminum honeycomb panels involves several key steps:

- Core Production: Aluminum foil is typically bonded and expanded to form the hexagonal honeycomb core.

- Skin Preparation: Aluminum sheets (skins) are cleaned and pre-treated, often with a primer.

- Adhesive Application: A high-performance adhesive is applied to both sides of the honeycomb core.

- Assembly: The prepared skins are bonded to the core under heat and pressure.

- Curing: The assembled panel is then cured in an oven to ensure a strong bond.

- Finishing: Finally, the panels are cut to size and may undergo surface finishing processes like painting or anodizing.

This precise process ensures the integrity and performance of the final aluminum honeycomb panel.

How to Choose the Right Aluminum Honeycomb Panel

Selecting the correct aluminum honeycomb panel type for your project requires careful consideration of several factors:

- Application Requirements: Determine if the panel will be used indoors or outdoors.

- Structural Needs: Assess the load-bearing requirements, span capability, and desired rigidity to choose the appropriate panel thickness and core density.

- Aesthetic Considerations: Select the desired surface finish (PVDF, PE, anodized, etc.) and color to match the design.

- Environmental Factors: Consider exposure to moisture, chemicals, or extreme temperatures, which will influence the choice of aluminum alloy and coating.

- Budget: Balance performance requirements with cost.

What Are Aluminum Honeycomb Panels?

An aluminum honeycomb panel is an advanced composite material. It consists of three main parts:

- Top Skin: A thin sheet of aluminum on the outside.

- Bottom Skin: Another thin sheet of aluminum on the other side.

- Honeycomb Core: This core is also typically made from aluminum.

This “sandwich” design makes the panel very stiff and strong, even though it is very light. The honeycomb structure efficiently distributes stress, preventing the panel from bending or warping.