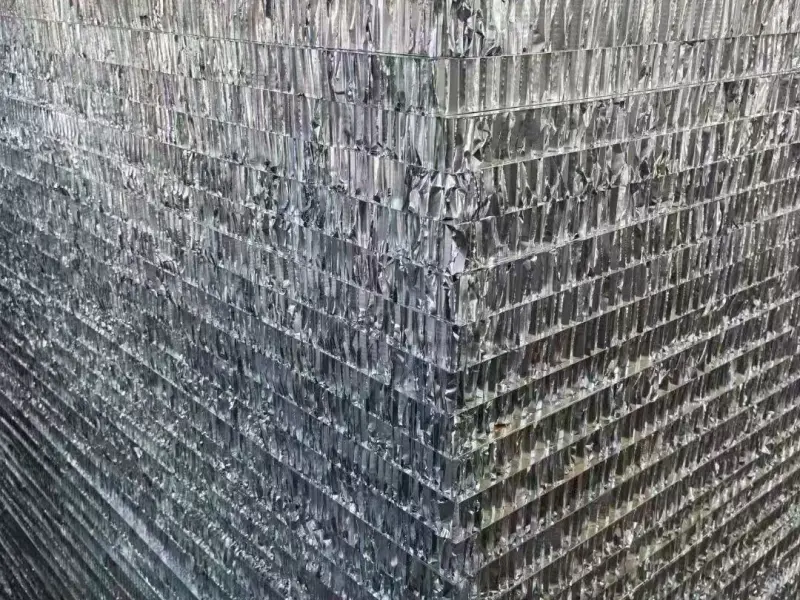

What Are Aluminum Honeycomb Core Panels?

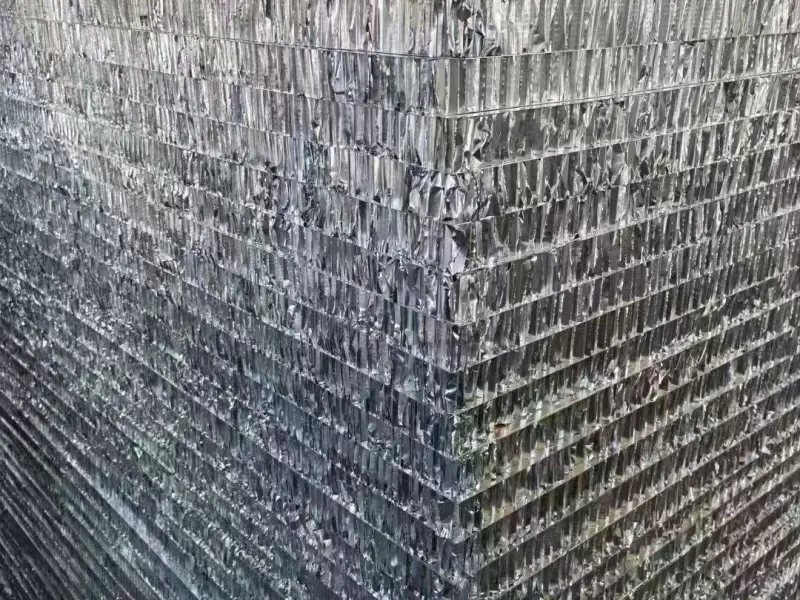

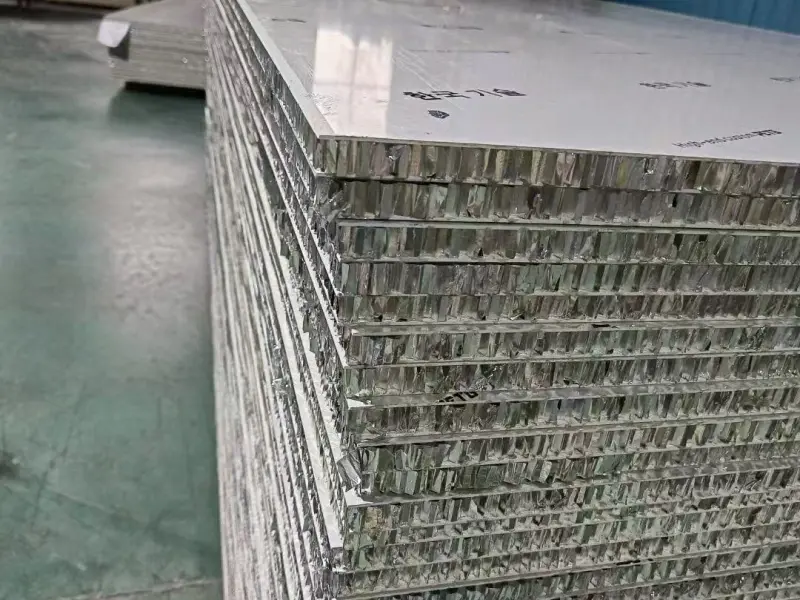

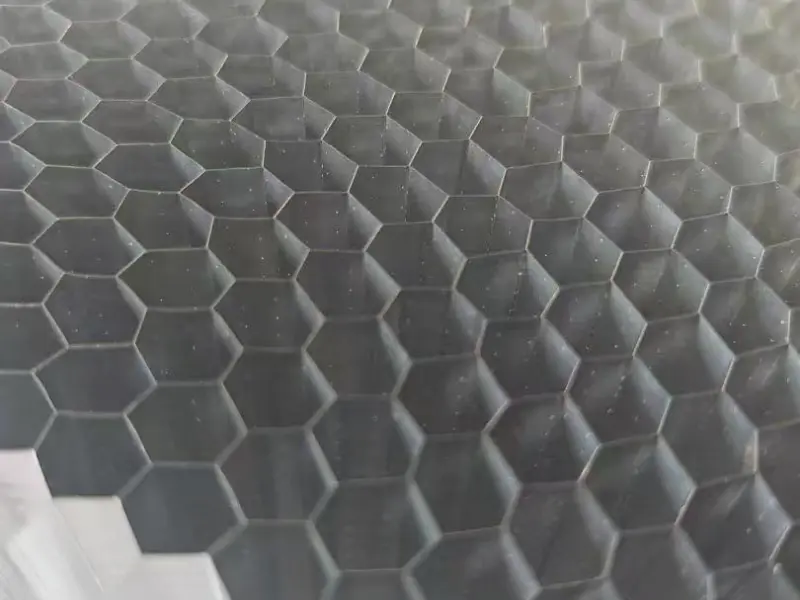

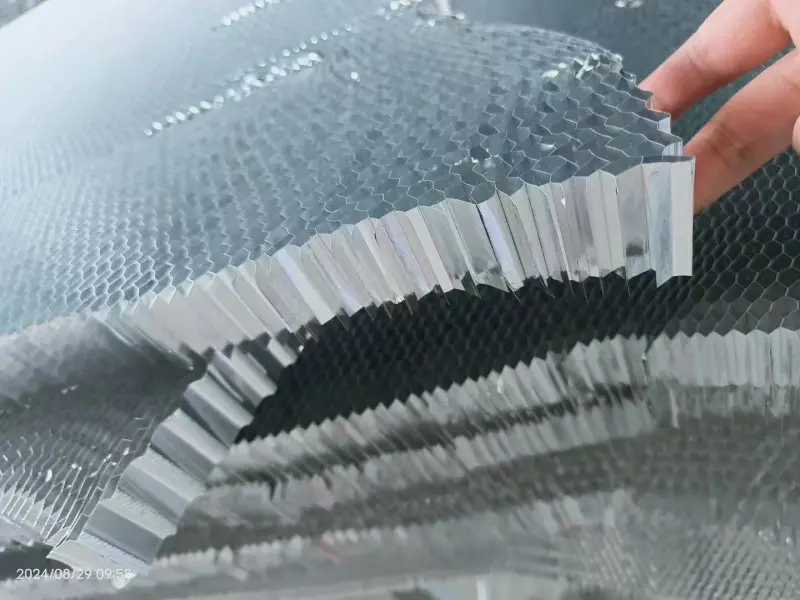

Aluminum honeycomb core panels are composite materials consisting of two thin aluminum sheets bonded to an aluminum honeycomb core. This innovative structure creates an exceptionally strong yet lightweight panel that offers superior performance compared to traditional solid panels. The hexagonal honeycomb pattern provides excellent strength-to-weight ratio, making these panels ideal for various applications where weight reduction is crucial without compromising structural integrity.

Types and specifications

Below is a clear table showing common numeric types and specifications. These typical values help you compare panels quickly.

| Type code | Core thickness (mm) | Cell size (mm) | Core density (kg/m3) | Total panel thickness (mm) | Typical face material | Approx. weight (kg/m2) |

|---|---|---|---|---|---|---|

| AHCP-10 | 6 | 3 | 50 | 8 | Aluminum 0.5 mm | 1.8 |

| AHCP-20 | 12 | 6 | 60 | 14 | Aluminum 1.0 mm | 3.2 |

| AHCP-30 | 25 | 9 | 70 | 26 | Aluminum 1.5 mm | 5.5 |

| AHCP-40 | 40 | 12 | 80 | 41 | Aluminum 2.0 mm | 8.2 |

| AHCP-60 | 60 | 16 | 90 | 62 | Composite / Aluminum 2.0 mm | 11.5 |

Notes:

- Core density and cell size affect strength, stiffness, and weight.

- Face material can be aluminum, stainless steel, fiberglass, or composite.

- Values are typical ranges; always check manufacturer data for exact figures.

Key Advantages of Aluminum Honeycomb Panels

Exceptional Strength and Lightweight Properties

The unique honeycomb structure delivers outstanding mechanical properties:

- High compressive strength despite minimal weight

- Excellent stiffness-to-weight ratio

- Superior impact resistance

- Outstanding load-bearing capacity

Durability and Longevity

These panels are built to last:

- Corrosion-resistant aluminum construction

- Weather-resistant for outdoor applications

- Minimal maintenance requirements

- Long service life in various environments

Versatility and Customization

Aluminum honeycomb panels offer:

- Multiple thickness options

- Various surface finishes

- Custom sizes and shapes

- Different core densities

Technical Specifications and Types

| Type | Panel Thickness (mm) | Core Size (mm) | Density (kg/m³) | Face Sheet Thickness (mm) | Typical Applications |

|---|---|---|---|---|---|

| Standard Grade | 10-50 | 6-10 | 5-9 | 0.5-1.0 | Partitions, ceilings |

| Structural Grade | 15-100 | 4-8 | 7-12 | 1.0-2.0 | Load-bearing structures |

| Fire Resistant | 10-60 | 6-10 | 6-10 | 0.8-1.5 | Public buildings, transport |

| Ultra-Light | 6-30 | 8-12 | 4-7 | 0.3-0.8 | Signage, displays |

| Architectural | 8-80 | 6-12 | 5-11 | 0.8-2.0 | Facades, cladding |

Applications Across Industries

Construction and Architecture

- Building facades and curtain walls

- Interior partitions and ceilings

- Elevator cladding and interiors

- Flooring systems

- Roofing solutions

Transportation Industry

- Aircraft interiors and components

- Railway carriage panels

- Marine vessel construction

- Truck and trailer bodies

- Automotive applications

Industrial and Commercial Uses

- Clean room partitions

- Machine guards and covers

- Exhibition stands and displays

- Signage and advertising boards

- Furniture and interior design

Manufacturing Process

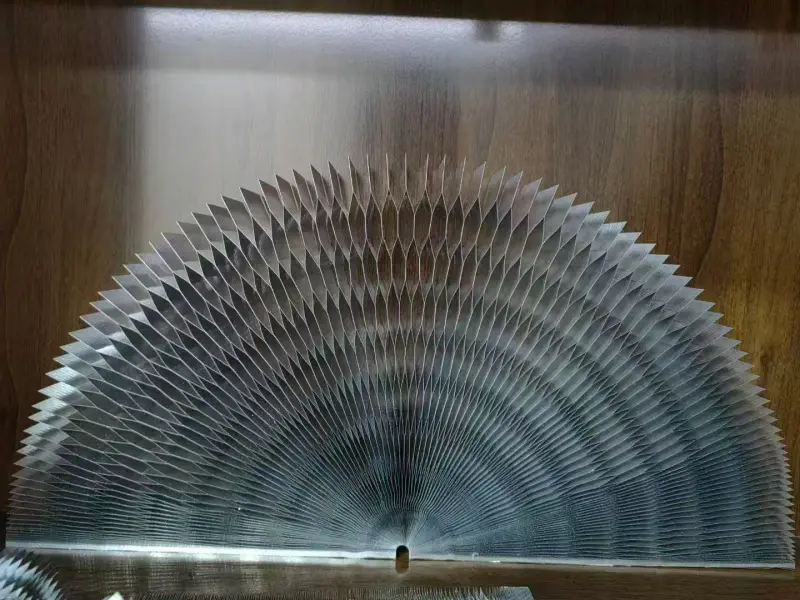

The production of aluminum honeycomb core panels involves:

- Aluminum sheet preparation and cleaning

- Honeycomb core expansion and shaping

- Adhesive application between layers

- Press curing under controlled conditions

- Quality inspection and testing

- Custom finishing and cutting

Installation and Maintenance

Easy Installation Features

- Lightweight for easy handling

- Simple cutting and shaping on-site

- Various joining methods available

- Minimal supporting structure required

Maintenance Requirements

- Regular cleaning with mild detergents

- Periodic inspection for damage

- Easy repair of minor damages

- Long-lasting performance with minimal upkeep

Environmental Benefits

Sustainability Features

- 100% recyclable aluminum materials

- Energy-efficient production process

- Reduced transportation energy due to lightweight

- Long lifespan reduces replacement needs

- Low waste generation during manufacturing

LEED Certification Contributions

- Recycled content qualifications

- Regional materials credit

- Low-emitting materials compliance

- Sustainable building design support

Cost Considerations

Initial Investment vs Long-term Savings

- Higher initial cost than some traditional materials

- Reduced installation costs due to lightweight

- Lower transportation expenses

- Minimal maintenance costs

- Long-term durability provides excellent ROI

Factors Affecting Pricing

- Panel thickness and size

- Surface finish requirements

- Customization needs

- Order quantity

- Delivery location

Quality Standards and Certifications

International Standards

- ASTM standards for composite panels

- EN European norms

- ISO quality management

- Fire safety certifications

- Environmental compliance certificates

Quality Control Measures

- Raw material testing

- Production process monitoring

- Final product inspection

- Performance testing

- Customer satisfaction tracking

Future Trends and Developments

Technological Advancements

- Improved adhesive technologies

- Enhanced surface treatments

- Smart panel integrations

- Sustainable manufacturing processes

- Customization capabilities expansion

Market Growth Areas

- Green building applications

- Transportation industry expansion

- Renewable energy projects

- Architectural innovation

- Industrial automation applications

Why Choose Aluminum Honeycomb Core Panels?

Aluminum honeycomb core panels represent the perfect combination of strength, lightness, and versatility. Their unique structure provides exceptional performance characteristics that make them suitable for a wide range of applications across multiple industries. From architectural marvels to transportation solutions, these panels offer unmatched benefits in terms of durability, sustainability, and cost-effectiveness.

The future looks bright for aluminum honeycomb technology as advancements continue to improve their performance and expand their applications. Whether you’re an architect, engineer, or designer, incorporating aluminum honeycomb core panels into your projects can provide significant advantages in terms of weight reduction, structural performance, and environmental sustainability.

When considering your next project, evaluate the benefits of aluminum honeycomb core panels – the smart choice for modern construction and manufacturing needs. Their proven track record and continuous innovation make them an excellent investment for any application requiring lightweight strength and durability.