Aluminium veneer is a lightweight, durable, and decorative panel widely used in modern construction and interior design. Known for its corrosion resistance, smooth finish, and easy installation, aluminium veneer panels are available in multiple classifications, thicknesses, and alloy grades.

Key Features and Benefits of Aluminium Veneer

Choosing aluminium veneer brings many advantages to any project.

- Durability: It resists wear and tear, making it perfect for long-term use.

- Lightweight: Easy to transport and install, reducing overall construction time and costs.

- Corrosion Resistance: Aluminium naturally forms a protective oxide layer, making it resistant to rust and decay.

- Aesthetic Appeal: Available in many colors and finishes, offering great design flexibility.

- Easy Maintenance: Simple to clean and keep looking new.

- Fire Resistance: Aluminium is a non-combustible material, adding a layer of safety.

- Recyclable: An environmentally friendly material that can be recycled.

Classification of Aluminium Veneer

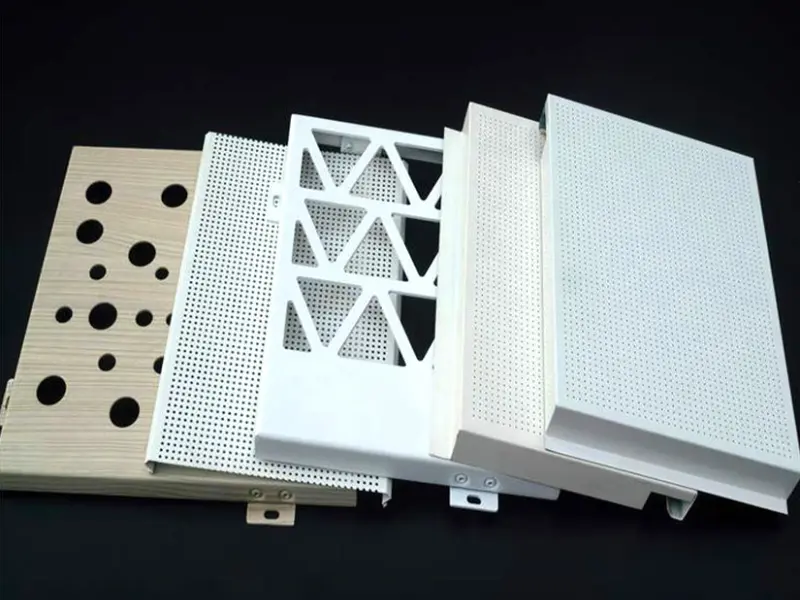

Aluminium veneer can be classified based on surface finish, application, and coating type.

| Classification Type | Details |

|---|---|

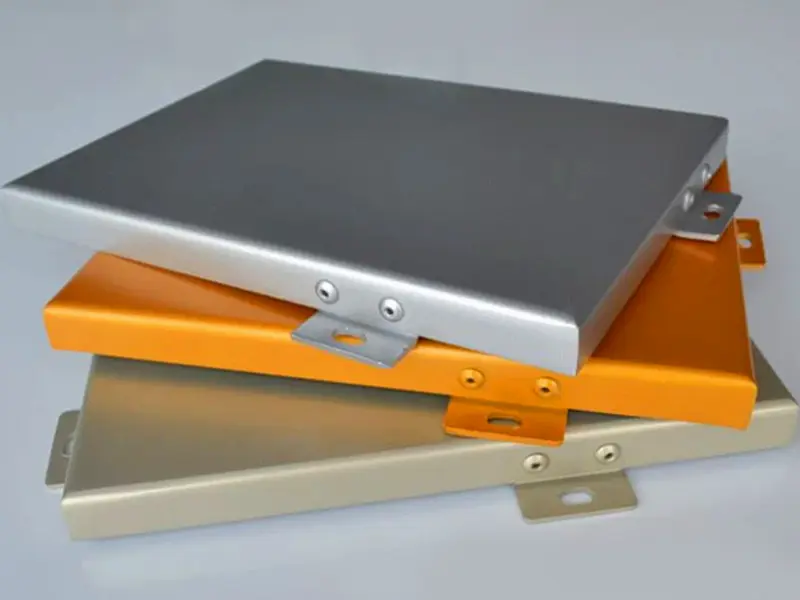

| By Surface Finish | Powder-coated, PVDF coated, Anodized |

| By Application | Exterior cladding, Interior wall, Ceiling, Column cover |

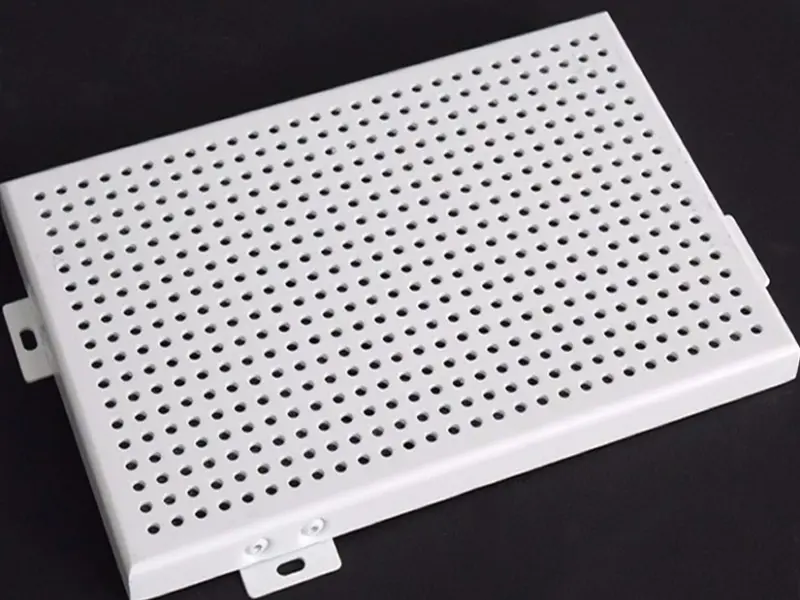

| By Surface Texture | Flat, Perforated, Wood-grain finish, Stone pattern |

| By Coating Durability | Standard coating (10–15 years), High-performance PVDF coating (20+ yrs) |

Thickness of Aluminium Veneer

| Thickness (mm) | Common Usage |

|---|---|

| 2.0 mm | Interior walls, decorative ceilings |

| 2.5 mm | Indoor cladding, lightweight structures |

| 3.0 mm | Exterior walls, facades, building decoration |

| 4.0 mm | High-strength cladding, outdoor applications |

Alloy Options for Aluminium Veneer

The alloy affects strength, flexibility, and corrosion resistance.

| Alloy Type | Properties & Benefits |

|---|---|

| 1100 | Good corrosion resistance, suitable for decoration |

| 3003 | High strength, good welding, durable façade use |

| 5005 | Excellent weather resistance, PVDF coating friendly |

| 5052 | Strong, corrosion-resistant, used in marine areas |

r sheets in architecture is 3003 H24 or 3003 H14 due to its good balance of strength and formability.

Packaging of Aluminium Veneer

Proper packaging for aluminium veneer is essential to protect the panels during transit and storage. This ensures they arrive at the construction site in perfect condition.

- Protective Film: Each panel typically has a thin plastic film on its surface to prevent scratches.

- Wooden Pallets: Panels are stacked on strong wooden pallets, offering a stable base.

- Corner Protectors: Cardboard or plastic protectors are often used on corners to prevent damage.

- Wooden Crates: For long-distance shipping or larger orders, panels may be packed in sturdy wooden crates for maximum protection.

- Strapping: Steel or plastic straps secure the panels to the pallet or within the crate.

Always check the aluminium veneer packaging upon arrival for any signs of damage.

Application Areas of Aluminium Veneer

The versatility of aluminium veneer makes it suitable for a wide range of applications.

- Building Facades: Used as external cladding for commercial and residential buildings.

- Interior Decoration: Feature walls, ceilings, and decorative elements inside buildings.

- Column Cladding: Wrapping around structural columns for an aesthetic finish.

- Ceilings: False ceilings in offices, malls, and public spaces.

- Canopies and Awnings: Providing shade and architectural interest.

- Signage: Durable and weather-resistant material for outdoor signs.

- Shop Fronts: Creating modern and attractive retail entrances.

- Tunnels and Underpasses: For durable and easy-to-clean wall linings.

Why Choose Aluminium Veneer for Your Project?

Aluminium veneer offers a compelling combination of durability, aesthetic flexibility, and practical benefits. Whether you are designing a new high-rise, renovating a commercial space, or simply updating an interior, aluminium façade panels provide a modern, long-lasting solution. Their ease of installation and low maintenance requirements further add to their appeal, making them a smart investment for any project.

What is Aluminium Veneer?

Aluminium veneer is a flat sheet of aluminium that for decorative and protective purposes. It is cut and shaped from larger aluminium sheets. These panels are then treated to ensure they are durable and look good for many years. Many architects and builders choose aluminium veneer sheets for their projects due because they offer both function and style.

RAQ

Q1: What is the price of aluminum veneer per square foot?

👉 Many buyers want to know the cost. The price usually depends on thickness (2mm, 3mm, 4mm), alloy (1100, 3003, 5005), surface coating (PVDF, powder coating), and order quantity.

Q2: Can aluminum veneer panels be customized in size and color?

👉 Yes, we offer custom sizes (such as 1220x2440mm, 1500x3000mm) and multiple surface colors including pearl white, metallic, and wood grain finishes.

Q3: What thickness of aluminum veneer is most popular for exterior wall cladding?

👉 The common thickness options are 2mm, 3mm, and 4mm. For indoor decoration, 2mm is enough, while for outdoor façade cladding, 3mm and 4mm are preferred.

Q4: What alloy is recommended for aluminum veneer panels?

👉 We usually recommend AA1100, 3003, or 5005 alloy, which have good corrosion resistance and excellent surface treatment performance.

Q5: How is aluminum veneer packaged for safe delivery?

👉 Panels are protected with PE protective film, packed with foam, wooden pallets, and strong export cartons to ensure safe shipping.

Q6: What is the minimum order quantity (MOQ) for aluminum veneer?

👉 The MOQ is usually 300–500 square meters, but we can also provide samples for testing before bulk orders.

Q7: How long is the production and delivery time?

👉 For regular orders, the lead time is 15–25 days, depending on the specifications and quantity.

Q8: Do you provide installation guidance or accessories?

👉 Yes, we can supply installation drawings, fixing systems, and technical support for your projects.