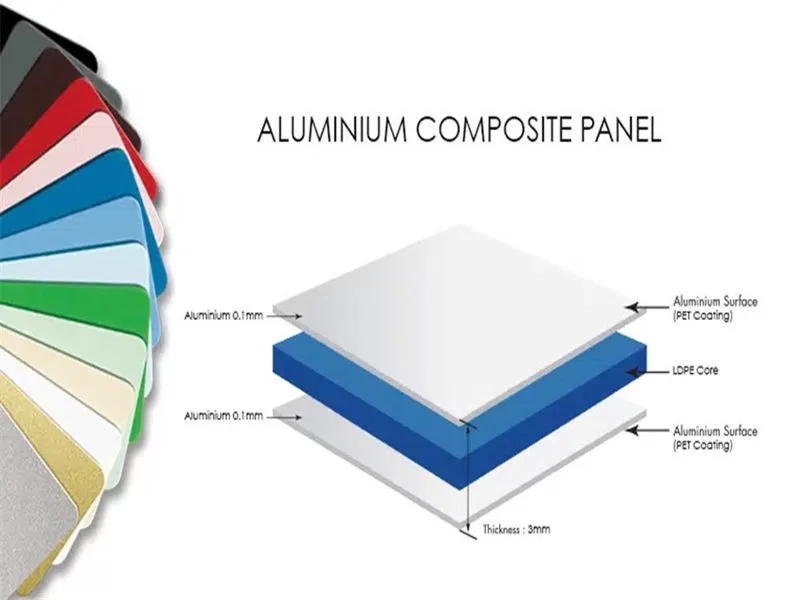

An aluminium composite panel (ACP) is a lightweight building material made of two aluminium sheets bonded to a non-aluminium core. These panels are widely used in modern construction for cladding, signage, and interior design due to their durability and sleek appearance.

Key Features:

Lightweight yet strong

Weather-resistant

Easy to install

Available in various colors and finishes

Specification of Aluminium Composite Panels

Here’s a table detailing common specifications for Aluminium Composite Panels:

| Specification Category | Details |

|---|---|

| Classification | Standard ACPs: For general use, interior & exterior. Fire-Retardant ACPs: Core contains mineral fillers for improved fire safety. Antibacterial ACPs: Special coating to inhibit bacteria growth. |

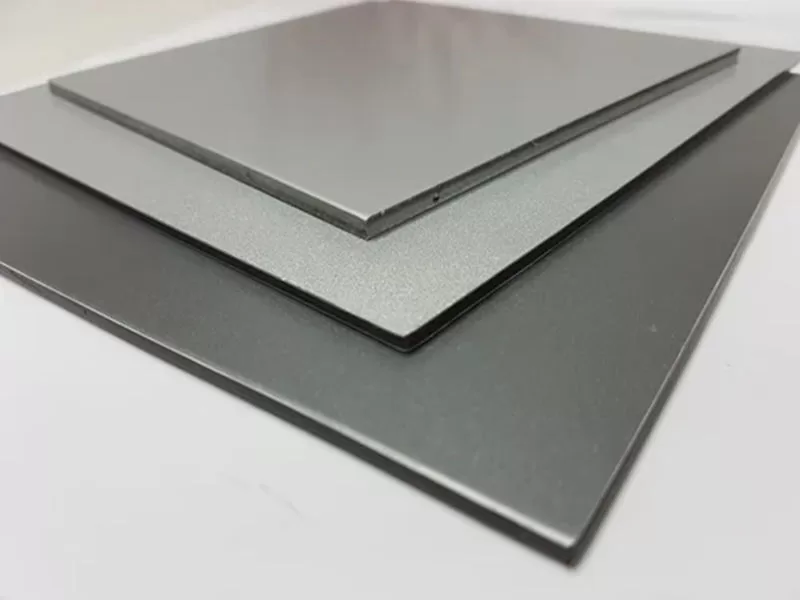

| Overall Thickness | 3mm: Common for interior applications, signage. 4mm: Most common for exterior cladding, facades. 5mm-6mm: Used for larger panels or specific structural needs. |

| Aluminium Skin Thickness | 0.12mm – 0.50mm: Thicker aluminium skins provide more rigidity and durability. For instance, 0.30mm or 0.40mm are popular for external cladding. |

| Alloy | Typically Alloy 1100 or 3003: These are common aluminium alloys known for their good workability and corrosion resistance, suitable for Aluminium Composite Panels. |

| Panel Width | Standard widths include 1000mm, 1220mm, 1250mm, 1500mm. Wider panels are also available for specific architectural designs. |

| Panel Length | Standard lengths range from 2440mm to 5000mm. Custom lengths can also be produced to minimize waste and improve installation efficiency. |

| Coating | PE (Polyester): Good for interior and short-term exterior use. PVDF (Polyvinylidene Fluoride): Excellent for long-term exterior use, providing superior weather and UV resistance, crucial for building facades. |

| Packaging | Wooden Pallets: Panels are stacked on wooden pallets, protected by plastic film and corner protectors. Suitable for large quantities. Bulk Shipping: For very large orders, panels may be directly loaded and secured in containers. |

What are the Disadvantages of Aluminium Composite Panels?

While Aluminium Composite Panels offer many benefits, it’s important to understand their limitations:

- Fire Safety Concerns (for standard PE core): Traditional ACPs with a polyethylene (PE) core can pose fire risks if not correctly specified or installed. However, fire-retardant (FR) ACPs with mineral-filled cores are available to address these concerns, offering improved safety for building cladding.

- Impact Resistance: Although generally durable, very thin Aluminium Composite Panels can be susceptible to dents from severe impacts, especially in high-traffic areas or at lower levels of a facade.

- Installation Skill: Proper installation requires trained professionals to ensure correct alignment, sealing, and secure fastening, particularly for exterior cladding where weather resistance is critical.

- Cost (compared to some alternatives): While cost-effective for their performance, Aluminium Composite Panels can be more expensive than simpler materials like painted plaster or certain types of traditional aluminium panels for basic applications.

What is the Life Expectancy of Aluminium Composite Panels?

The life expectancy of Aluminium Composite Panels largely depends on the quality of the product, particularly the coating, and the environment they are installed in. High-quality ACPs with PVDF coatings, often used for exterior cladding and facades, can last for 20 to 30 years or even more.

Factors influencing life expectancy include:

- Coating Type: PVDF coatings offer superior UV and weather resistance compared to PE coatings, extending the life of the panel significantly.

- Aluminium Skin Thickness: Thicker aluminium skins provide more rigidity and are less prone to deformation over time.

- Environmental Conditions: Exposure to extreme temperatures, high UV radiation, pollution, or corrosive elements can affect the longevity of the panels.

- Maintenance: Regular cleaning helps maintain the aesthetic appeal and integrity of the Aluminium Composite Panel surface.

What is the Difference Between an Aluminum Panel and an Aluminum Composite Panel?

It’s easy to confuse an aluminium panel with an Aluminium Composite Panel (ACP), but they are distinct products:

| Feature | Aluminium Panel (Solid Aluminium Sheet) | Aluminium Composite Panel (ACP) |

|---|---|---|

| Structure | A single, solid sheet of aluminium. | Two thin aluminium sheets bonded to a non-aluminium core. |

| Weight | Heavier for the same thickness and rigidity. | Lighter, especially for large formats, due to its composite structure. |

| Rigidity/Flatness | Can be prone to oil-canning or warping in large sizes without extensive reinforcement. | Excellent flatness and rigidity due to the sandwich structure, even in large sizes. |

| Fabrication | Typically requires welding, bending, and specialized tools. | Easier to cut, rout, fold, and bend with simpler tools, offering more design flexibility for facades and signage. |

| Thermal Expansion | Higher thermal expansion, which needs careful consideration in design. | Lower thermal expansion due to the core material, leading to less visible distortion. |

| Cost | Can be more expensive for the equivalent performance in terms of flatness and rigidity for cladding. | Generally more cost-effective for large, flat architectural applications. |

| Application Suitability | Often used for highly customized shapes, small components, or where solid metal is explicitly required. | Ideal for large-scale exterior cladding, building facades, interior wall linings, and signage. |

In summary, while both are made from aluminium, an Aluminium Composite Panel offers a unique combination of lightness, rigidity, flatness, and ease of fabrication, making it highly versatile for modern architectural and design applications.

Applications of Aluminium Composite Panels

Aluminium Composite Panels are incredibly versatile and are used in a wide range of applications due to their durability, aesthetics, and ease of use. Key application areas include:

- Building Facades and Exterior Cladding: This is one of the most common uses. ACPs provide a modern, sleek appearance and protection against weather elements for commercial and residential buildings.

- Interior Decoration and Wall Linings: Used for interior walls, ceilings, columns, and partitions in offices, hotels, and retail spaces, offering a clean and contemporary finish.

- Signage and Advertising Boards: Their smooth, flat surface and ability to be easily cut and routed make them perfect for outdoor and indoor signs, display boards, and corporate identity branding.

- Soffits and Canopies: Providing durable and attractive coverings for building eaves, entrance canopies, and awnings.

- False Ceilings: Used in large commercial spaces for suspended ceilings, offering good acoustics and aesthetic appeal.

- Retail Storefronts: Enhancing the visual appeal of shops and showrooms with a modern and elegant look.

- Tunnels and Metro Stations: Chosen for their durability, fire resistance (especially FR types), and ease of maintenance in high-traffic public areas.

- Modular Buildings and Portable Cabins: Their lightweight and easy fabrication make them suitable for quick construction of temporary or modular structures.

Aluminium Panel vs. Aluminium Composite Panel

| Feature | Aluminium Panel | Aluminium Composite Panel |

|---|---|---|

| Weight | Heavier | Lightweight |

| Strength | Solid but less flexible | Strong yet bendable |

| Cost | Higher | More affordable |

| Insulation | Poor | Better (due to core layer) |

Best choice? ACPs for cladding, solid panels for heavy-duty structures.

What is an Aluminium Composite Panel?

Aluminium Composite Panels (ACPs) are modern building materials widely used for exterior facades, interior decoration, and signage. An Aluminium Composite Panel is essentially a flat panel that consists of two thin aluminium sheets bonded to a non-aluminium core. This core is typically polyethylene or a mineral-filled fire-retardant material. The outer aluminium layers are often coated with a special paint, providing excellent color retention and weather resistance. This unique sandwich structure gives ACPs their outstanding properties, making them a popular choice in the construction industry.