Auminum pipe jacketing plays a vital role. It’s a protective outer layer designed to shield insulation and the pipes themselves from damage, moisture, and environmental elements. Choosing the right aluminum jacketing ensures long-term efficiency and safety for various systems.

Specifications of Aluminum Pipe Jacketing

| Item | Specification |

|---|---|

| Material | Aluminum 1100, 1060, 3003, 3105, 5005 |

| Temper | H14, H16, H24, H26 |

| Thickness | 0.3 mm – 1.0 mm |

| Width | 914 mm (36”), 1000 mm (39.4”), etc. |

| Length | Coil or cut-to-length sheets |

| Finish | Smooth, Stucco embossed, Corrugated |

| Moisture Barrier | Polyfilm, Kraft paper, Polysurlyn |

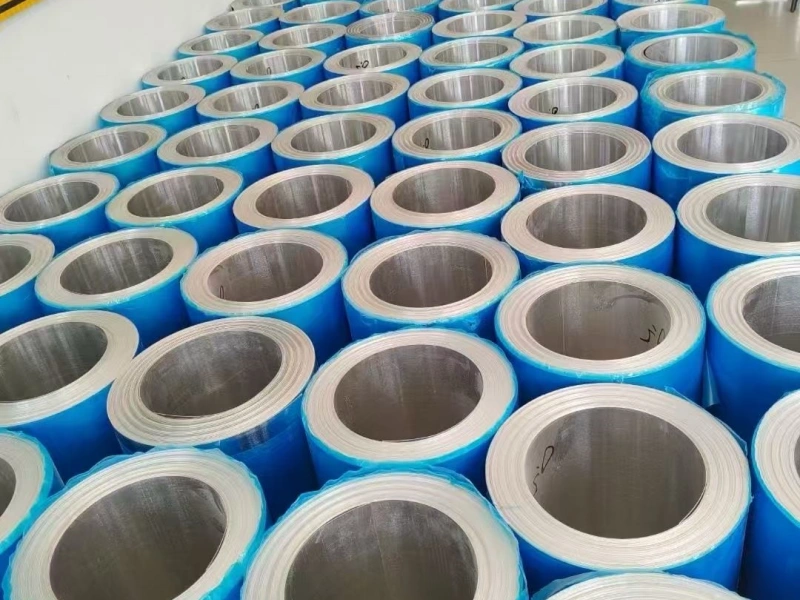

| Packaging | Wooden pallets, wrapped in plastic |

Custom sizes and alloys are available to meet specific project requirements.

Classification

Aluminum pipe jacketing comes in different forms and finishes, each suited for specific environments and aesthetic preferences. Understanding these classifications helps in selecting the best option for your project.

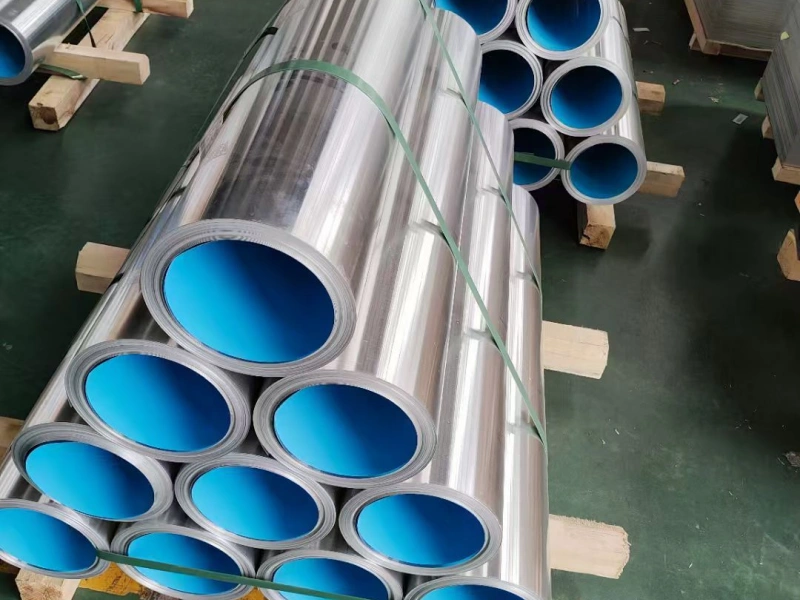

- Smooth Finish: This is the most basic form of aluminum jacketing. It offers a clean, reflective surface, which can sometimes help in radiating heat away or reflecting light. It’s often used where a polished look is desired.

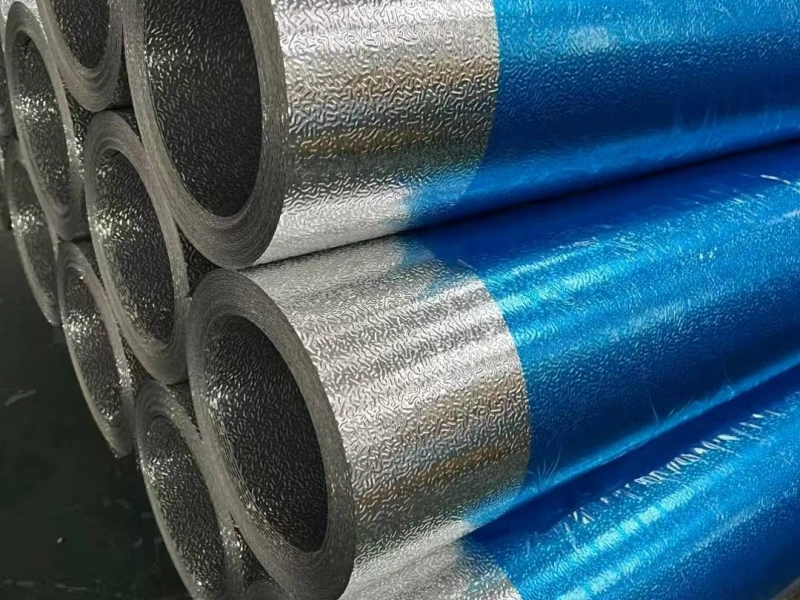

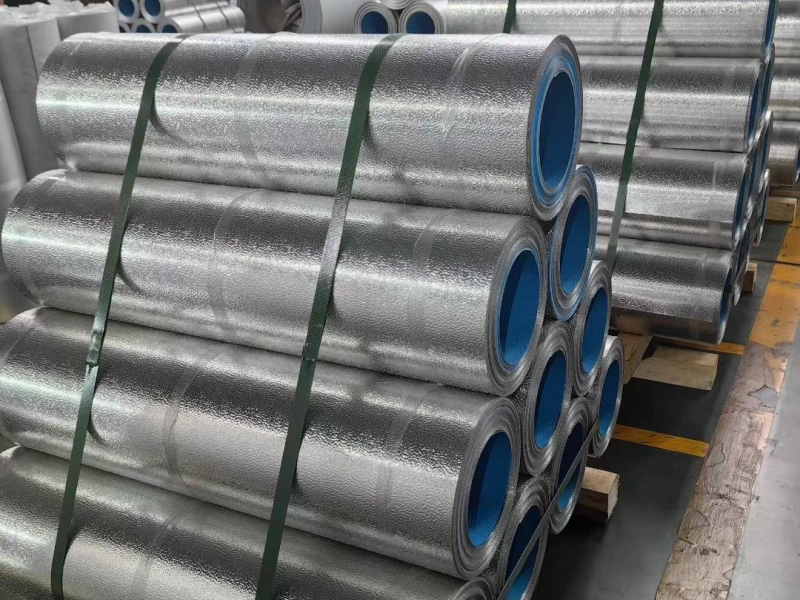

- Stucco Embossed Finish: This is perhaps the most popular type. The “stucco” pattern is a small, random, textured dimple design on the surface. This embossing provides several benefits:

- It reduces glare from sunlight.

- It hides minor dents and scratches better than a smooth finish.

- It adds rigidity to the aluminum sheet, making it stronger and less prone to oil canning (a wavy appearance).

- It helps in dissipating minor moisture or condensation.

- Corrugated Finish: Less common for standard pipe jacketing, corrugated aluminum sheets are often used for larger diameters or specific applications where enhanced rigidity and drainage channels are needed. The (wave) pattern adds significant strength.

Each finish maintains the core protective qualities of aluminum pipe jacketing while offering distinct advantages in terms of appearance and handling.

Understanding Aluminum Alloys for Jacketing

The performance of aluminum pipe jacketing heavily depends on the specific aluminum alloy used. Different alloys offer varying levels of strength, corrosion resistance, and workability. The most common alloys for aluminum pipe jacketing are 3003 and 3105.

- Aluminum Alloy 3003: This is the most widely used alloy for aluminum jacketing applications. It’s a non-heat-treatable alloy, meaning its strength isn’t increased by heating. Its popularity stems from:

- Excellent Corrosion Resistance: Especially good against atmospheric corrosion and many chemicals, which is crucial for outdoor pipe protection.

- Good Workability: It’s easy to form, bend, and cut, making installation straightforward for pipe jacketing.

- Moderate Strength: Strong enough for most jacketing needs without being overly rigid, allowing for easy handling and fitting around pipes.

- Aluminum Alloy 3105: This alloy is very similar to 3003 but contains a slightly higher percentage of magnesium. This small difference gives 3105:

- Improved Strength: It’s a bit stronger than 3003, which can be beneficial in applications where minor impacts might occur or where greater rigidity is desired.

- Good Formability and Weldability: While slightly stronger, it still retains good forming characteristics, making it suitable for various aluminum jacketing needs.

- Good Corrosion Resistance: Like 3003, it offers excellent resistance to corrosion, ensuring the longevity of the aluminum pipe jacketing.

Both 3003 and 3105 alloys are excellent choices for aluminum pipe jacketing due to their balance of corrosion resistance, strength, and ease of fabrication. The choice often comes down to specific project requirements and budget.

Key Benefits

Investing in aluminum pipe jacketing provides a multitude of benefits for any system requiring insulation protection.

- Superior Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air. This layer self-repairs, offering outstanding resistance to rust, chemicals, and saltwater environments. This is a primary reason for its use in pipe protection.

- Exceptional Durability and Longevity: Aluminum jacketing is robust. It can withstand harsh weather conditions, UV radiation, and physical impacts, ensuring the underlying insulation and pipes are protected for many years, reducing the need for frequent maintenance or replacement.

- Enhanced Thermal Insulation Performance: By protecting the insulation from moisture, aluminum pipe jacketing ensures that the thermal barrier remains effective. This prevents heat loss or gain, leading to significant energy savings and stable process temperatures.

- Aesthetic Appeal: The clean, metallic look of aluminum jacketing gives industrial facilities a neat and professional appearance. Stucco embossed finishes can further enhance this by reducing glare and hiding imperfections.

- Ease of Installation: Aluminum is lightweight and can be easily cut, bent, and fastened, making the installation process efficient and less labor-intensive. This reduces overall project costs.

- Low Maintenance: Once installed, aluminum pipe jacketing requires minimal maintenance. Its inherent properties mean it doesn’t degrade easily, saving time and resources over its lifespan.

- Fire Resistance: Aluminum is non-combustible, adding an extra layer of safety to industrial applications.

Where is Aluminum Pipe Jacketing Used?

The versatility and protective qualities of aluminum pipe jacketing make it indispensable across a wide range of industries and applications.

- Oil and Gas Industry: Protecting pipelines, storage tanks, and processing units from harsh outdoor elements and extreme temperatures.

- Chemical Plants: Offering corrosion resistance against various chemical fumes and spills, protecting critical infrastructure.

- Power Generation Facilities: Insulating steam lines, turbines, and other high-temperature components to maintain energy efficiency.

- HVAC Systems: Used on large ductwork and chilled water lines in commercial and industrial buildings to prevent condensation and maintain temperature.

- Food and Beverage Processing: Ensuring hygiene and temperature control for pipes carrying food products or cleaning agents.

- Pharmaceuticals: Maintaining sterile environments and consistent temperatures for sensitive processes.

- Marine Environments: Its excellent corrosion resistance makes it ideal for offshore platforms, ships, and coastal facilities where saltwater exposure is common.

- Commercial and Industrial Buildings: General insulation protection for heating, cooling, and plumbing systems.

Key Features to Consider When Choosing

When selecting aluminum pipe jacketing, a few key features should be considered to ensure optimal performance.

- Thickness: The thickness of the aluminum sheet affects its durability and resistance to damage. Common thicknesses range from 0.016 inches to 0.040 inches. Thicker gauges offer more protection but are also less flexible.

- Moisture Barrier: For ultimate moisture protection, some aluminum jacketing comes with a factory-applied moisture barrier (like a polysurlyn or kraft paper layer) on the inside surface. This barrier prevents galvanic corrosion (when two different metals react in the presence of an electrolyte) between the aluminum and the pipe or insulation and acts as an additional vapor retarder.

- Surface Finish: As discussed, smooth, stucco embossed, or corrugated finishes offer different benefits in terms of appearance, rigidity, and glare reduction.

- Compliance with Standards: Ensure the aluminum jacketing meets industry standards for materials and performance, guaranteeing quality and reliability.

Installation and Maintenance Tips

Proper installation is key to the effectiveness of aluminum pipe jacketing. Ensure that all seams are overlapped correctly and sealed with appropriate sealants and bands to prevent moisture ingress. Tools designed for sheet metal work will make the job easier. Once installed, aluminum jacketing requires very little maintenance. Periodic visual inspections for any physical damage or loose seams are usually sufficient to ensure its long-term performance.

What is Aluminum Pipe Jacketing?

Aluminum pipe jacketing is a thin sheet of aluminum, often cut into rolls or pre-formed sections, used to cover thermal insulation on pipes, ducts, and tanks. Its primary purpose is to protect the underlying insulation from physical damage, UV radiation, and, most importantly, moisture ingress. When insulation gets wet, it loses its effectiveness, leading to energy loss and potential corrosion of the pipe beneath. Aluminum jacketing creates a robust barrier, keeping the insulation dry and performing optimally. It’s a common sight in many industrial settings due to its lightweight nature, excellent durability, and clean appearance.

Conclusion

Aluminum pipe jacketing is an essential component for protecting insulated piping systems across numerous industries. Its lightweight nature, exceptional durability, superior corrosion resistance, and ease of installation make it an ideal choice. By choosing the correct alloy, like 3003 or 3105, and considering the finish and features, you can ensure your pipes and insulation are well-protected for years to come, leading to improved energy efficiency, reduced maintenance, and enhanced operational safety. Investing in high-quality aluminum pipe jacketing is a smart decision for any infrastructure project.