Aluminum honeycomb panels are a modern and versatile material widely used in construction, transportation, and many other industries. Known for their strength, lightweight nature, and durability, these panels are an excellent choice for various applications. Finding reliable aluminum honeycomb panel suppliers is key to getting the best quality products for your project.

What Are Aluminum Honeycomb Panels?

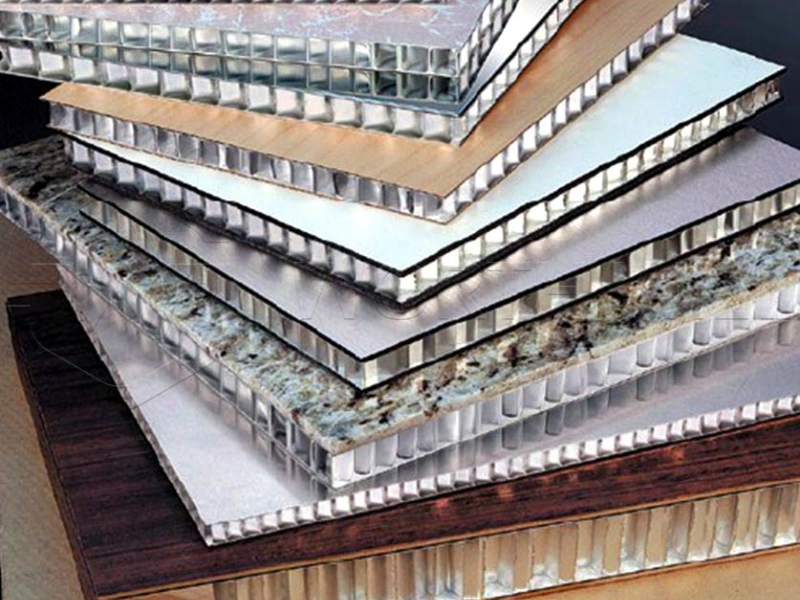

An aluminum honeycomb panel is a type of sandwich composite material. It consists of two thin aluminum sheets (face and back panels) bonded to a central core made of aluminum honeycomb core. The structure of the core resembles a honeycomb, which provides exceptional rigidity and strength while keeping the overall weight low.

These panels are typically made using aerospace-grade aluminum alloy sheets coated with durable finishes that offer excellent weather resistance. The face and back sheets are bonded to the aluminum honeycomb core using high-strength adhesives under high temperature and pressure, creating a strong, lightweight, and flat panel.

Why Choose Aluminum Honeycomb Panels?

There are many reasons why aluminum honeycomb panels are a preferred choice for designers and builders:

- Lightweight: Their honeycomb structure makes them significantly lighter than solid aluminum panels or other traditional materials.

- High Strength and Rigidity: The sandwich construction provides excellent structural integrity and resistance to bending and shear forces.

- Durability: They are resistant to corrosion, moisture, and extreme temperatures.

- Flatness: Aluminum honeycomb panels offer excellent flatness, making them ideal for large surface applications.

- Fire Resistance: Aluminum is non-combustible, contributing to fire safety.

- Acoustic and Thermal Insulation: The trapped air within the honeycomb cells provides some level of insulation.

- Versatility: They can be easily cut, shaped, and installed.

Applications of Aluminum Honeycomb Panels

Originating from aerospace technology, aluminum honeycomb panels have found extensive use in civilian applications. Their unique properties make them suitable for a wide range of projects, from buildings to boats.

Here are some common applications for aluminum honeycomb panels:

- Interior decoration projects in buildings.

- Building curtain walls and exterior wall cladding.

- Advertising boards and signage.

- Construction in ships and marine vessels.

- Components in the aerospace manufacturing industry.

- Indoor partitions and dividing walls.

- Product display stands and exhibition booths.

Choosing the right aluminum honeycomb panel suppliers ensures you get panels suitable for your specific application.

Aluminum Honeycomb Panel Specifications

When you look to buy aluminum honeycomb panel, you will encounter various specifications. Here are some typical details you might see:

| Products | Aluminium Honeycomb Sandwich Panel |

|---|---|

| Width | 1220-1500mm |

| Length | 2440-3200mm |

| Thickness | 7-25mm |

| Mention | Customized design according to requirements |

Suppliers can often provide panels with dimensions and specifications tailored to meet specific project needs.

Aluminum Honeycomb Panel Thickness

The thickness of an aluminum honeycomb panel is a crucial specification that affects its strength, rigidity, and cost. Common thicknesses range from 7mm to 25mm, but thicker panels can also be manufactured for specific structural requirements. The choice of thickness depends on the application, the required span, and the load the panel needs to support. Thicker panels with denser aluminum honeycomb core provide greater rigidity.

Price Factors for Aluminum Honeycomb Panels

The cost of aluminum honeycomb panels can vary depending on several factors. If you are looking to buy aluminum honeycomb panel, consider these points that influence the price:

- Panel Thickness: Thicker panels generally cost more due to increased material usage.

- Panel Size: Larger custom sizes may be more expensive than standard sizes.

- Aluminum Alloy Type: The specific grade of aluminum alloy used for the face sheets can affect the price.

- Surface Coating: Different coatings like PVDF or Polyester have varying costs and durability. PVDF coatings are typically more expensive but offer superior weather resistance.

- Honeycomb Core Density: The cell size and foil thickness of the aluminum honeycomb core impact its density and the panel’s strength, thus affecting the price. A higher density core is usually more expensive.

- Order Volume: Buying in larger quantities often results in a lower per-panel price.

- Supplier: Different aluminum honeycomb panel suppliers will have different pricing structures based on their manufacturing costs, location, and business model.

Understanding these factors helps you get a clearer picture of the investment required when you decide to buy aluminum honeycomb panel.

Types of Aluminum Honeycomb Panels

Beyond standard panels, there are various types available from aluminum honeycomb panel suppliers. These variations might include:

- Different Surface Finishes: Panels can have various finishes like solid colors, metallic colors, stone or wood patterns, and even mirrored surfaces.

- Core Types: While the core is typically aluminum honeycomb, variations in cell size and foil thickness lead to different strengths and densities, such as Aluminum Honeycomb Core—Commercial Grade suitable for standard applications.

- Edge Configurations: Panels can be supplied with open or closed edges, depending on the installation method and required finish.

- Curved Panels: Some suppliers can produce curved aluminum honeycomb panels for architectural features.

When looking for honeycomb panel suppliers in 2025, inquire about the different types they offer to find the best fit for your project.

Popular Aluminum Honeycomb Panel Types

Some of the most popular types of aluminum honeycomb panels are those with PVDF coatings, known for their excellent long-term weather resistance and color retention, making them ideal for exterior applications like curtain walls. Panels with standard Polyester coatings are often used for interior decoration. Panels with a Commercial Grade Aluminum Honeycomb Core are widely used due to their balance of strength and cost-effectiveness for many standard construction and decorative purposes.

Packaging

Proper packaging is essential to protect aluminum honeycomb panels during transport and storage. Reputable aluminum honeycomb panel suppliers use robust packaging methods, typically involving wooden crates or pallets, often with protective film on the panel surfaces and corner protection. This ensures that the panels arrive at the site in excellent condition, ready for installation.

How to Buy Aluminum Honeycomb Panel

If you are planning to buy aluminum honeycomb panel, the process usually involves:

- Defining Your Requirements: Determine the size, thickness, color, finish, and quantity of panels needed. Consider the application and environmental conditions.

- Requesting Quotes: Contact several aluminum honeycomb panel suppliers and request detailed quotations based on your specifications.

- Evaluating Suppliers: Compare quotes, production lead times, minimum order quantities, and the supplier’s reputation and quality certifications.

- Placing Your Order: Once you’ve chosen a supplier, finalize the order details and payment terms.

- Delivery: Arrange for the delivery of the panels to your project site.

Working with experienced honeycomb panel suppliers in 2025 can make this process smooth and ensure you receive high-quality products.

Choosing the Right Honeycomb Panel Suppliers in 2025

Selecting the best aluminum honeycomb panel suppliers is crucial for the success of your project. Here are some factors to consider when making your choice in 2025:

- Experience and Reputation: Look for suppliers with a proven track record and positive customer reviews.

- Quality Control: Ensure the supplier adheres to strict quality control standards and has relevant certifications (like ISO 9001).

- Customization Capabilities: If your project requires custom sizes, shapes, or finishes, choose a supplier who can meet these needs.

- Production Capacity and Lead Time: Verify that the supplier can handle the required volume and deliver within your project timeline.

- Technical Support: Good suppliers offer technical assistance and advice on panel selection and installation.

- Pricing: While not the only factor, competitive pricing is important.

When researching honeycomb panel suppliers in 2025, you might encounter names like WORTHWILL, known for providing quality aluminum honeycomb panels. Researching and comparing multiple options will help you find the perfect partner for your needs.

Conclusion

Aluminum honeycomb panels are an innovative and high-performance material offering significant advantages in terms of weight, strength, and durability for a wide range of applications. From modern building facades to lightweight interiors, they provide a versatile solution. Finding reputable aluminum honeycomb panel suppliers is vital to source high-quality panels that meet your project’s specific requirements. By considering factors like panel specifications, price determinants, panel types, and the supplier’s credentials, you can confidently buy aluminum honeycomb panel and ensure a successful outcome for your construction or design project in 2025 and beyond.