The aluminum jacket for duct insulation is more than just a cover; it’s an integral component of any robust and efficient insulation system.

From its varied thickness options and specialized alloy choices to its protective moisture barriers and flexible types like aluminum roll jacketing, it provides unparalleled protection. For effective thermal performance and long-term durability, choose the right aluminum jacket for pipe insulation for your project needs.

Classification

Aluminum jacketing is a protective layer applied over duct and pipe insulation. It prevents moisture, UV rays, and mechanical damage, ensuring long-lasting performance of insulation systems.

Types of classification:

- By surface finish: Smooth, Corrugated, Stucco Embossed

- By moisture barrier: With Kraft, Polykraft, or PVDF film

- By form: Coil, Sheet, or Roll

Thickness

The thickness of aluminum jacketing is chosen based on application environment, duct size, and protection level.

Table: Common Thickness Options

| Thickness (mm) | Typical Use | Durability Level |

|---|---|---|

| 0.3 – 0.4 | Small ducts, indoor applications | Light |

| 0.5 – 0.6 | Standard pipe and duct insulation | Medium |

| 0.7 – 0.9 | Industrial and outdoor duct protection | Heavy |

| 1.0 and above | Harsh environments, marine and petrochemical | Extra Heavy |

Alloy

The most common alloys for aluminum duct jacketing are:

- Alloy 1060: Pure aluminum, lightweight, economical

- Alloy 3003: Good corrosion resistance, widely used

- Alloy 5005: Strong weather resistance, suitable for outdoor

- Alloy 3105: Enhanced strength and paint finish option

Table: Alloy Properties

| Alloy | Features | Best Application |

|---|---|---|

| 1060 | High purity, low cost | Indoor, low-demand environments |

| 3003 | Anti-rust, moderate strength | General duct & pipe insulation |

| 5005 | Superior corrosion resistance | Outdoor HVAC & chemical plants |

| 3105 | Paintable, stronger surface | Decorative jacketing, roofing |

Types

Aluminum jacketing for duct insulation is available in different types:

- Smooth aluminum jacketing: Classic appearance, easy handling

- Stucco embossed aluminum jacketing: Better surface strength, hides scratches

- Corrugated aluminum jacketing: High rigidity, ideal for industrial pipes

- Coil & roll jacketing: Continuous length for large-scale duct coverage

Alloy Types for Jacketing

Different aluminum alloys offer varying properties:

| Alloy | Characteristics | Best For |

|---|---|---|

| 1100 | High corrosion resistance, flexible | Indoor applications, mild environments |

| 3003 | Good strength, workability | General outdoor use, standard ducts |

| 5052 | Excellent corrosion resistance | Coastal areas, chemical plants |

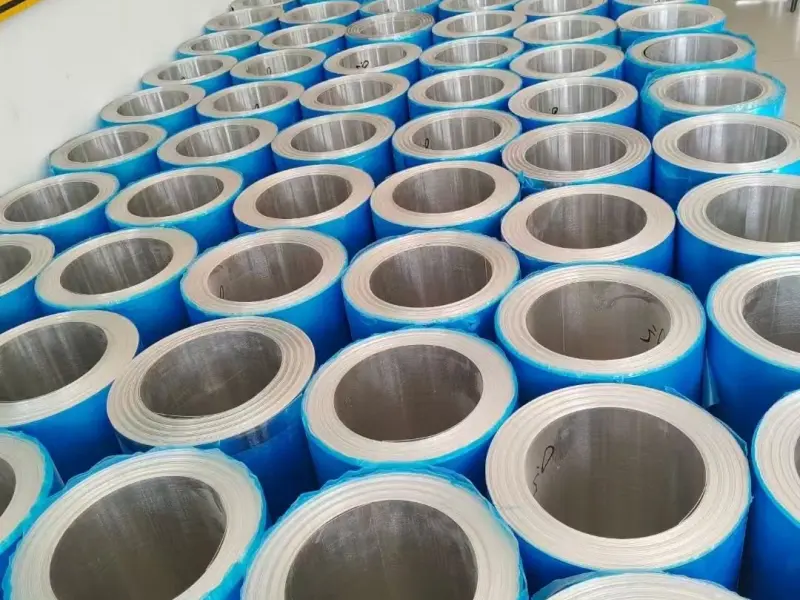

Factory: Producing Quality Aluminum Jacketing

A reliable factory for aluminum jacket for duct insulation plays a crucial role in the quality and performance of the final product. A reputable manufacturer will:

- Source High-Quality Raw Materials: Ensuring the correct aluminum alloy and temper are used.

- Employ Advanced Manufacturing Processes: Utilizing precision rolling, embossing, and laminating equipment.

- Implement Strict Quality Control: Conducting tests for thickness, tensile strength, barrier integrity, and surface finish.

- Offer Customization: Providing specific sizes, finishes (like stucco embossed), and moisture barriers as per client needs.

- Adhere to Standards: Meeting international specifications like ASTM, EN, and relevant industry standards.

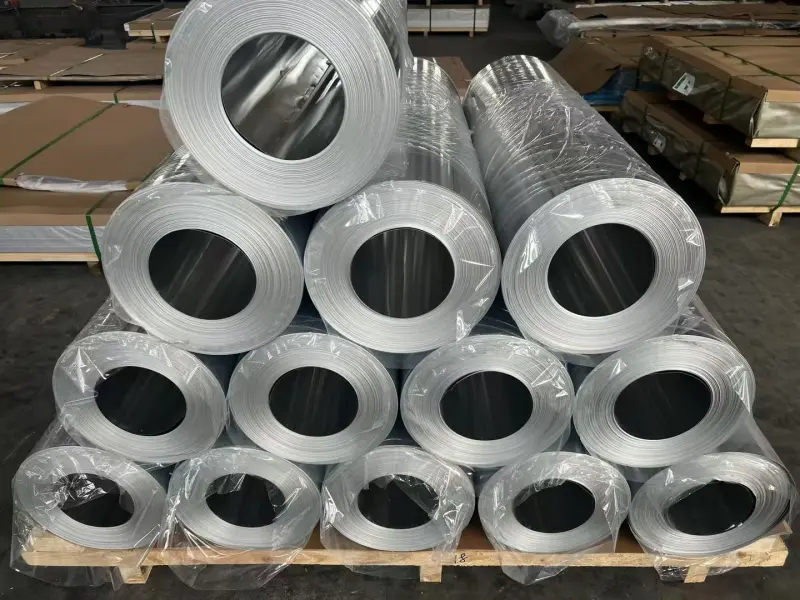

Packaging

Aluminum jackets are packed for safe transport:

- Coil form: wrapped with waterproof paper + steel straps

- Sheet form: wooden pallets, corner protection

- Export packing: seaworthy and moisture-proof packaging

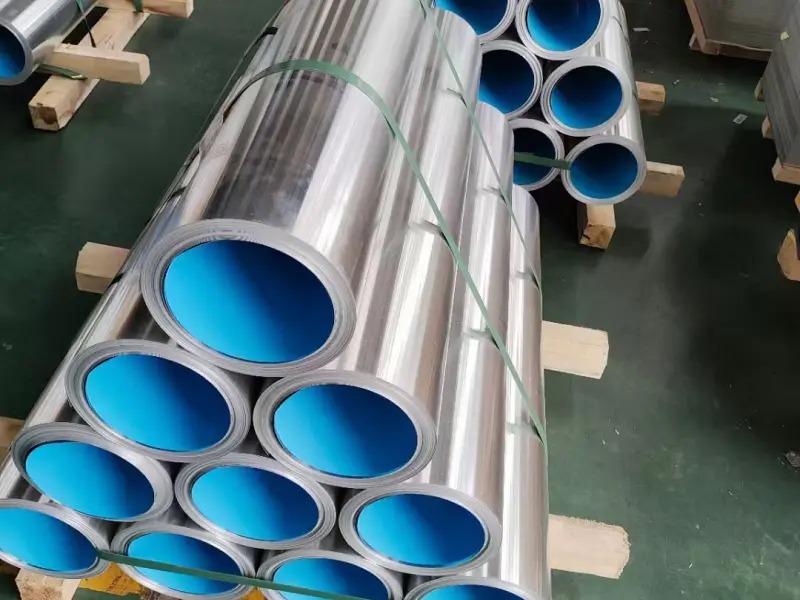

Aluminum Jacket for Pipe Insulation

Besides ducts, aluminum jacketing is also widely used for pipe insulation. It covers insulation layers in HVAC, oil, gas, and chemical industries.

Table: Pipe Insulation Jacket Sizes

| Pipe Diameter (inch) | Recommended Thickness (mm) | Alloy Options |

|---|---|---|

| 1 – 6 | 0.4 – 0.5 | 1060, 3003 |

| 8 – 24 | 0.6 – 0.8 | 3003, 5005 |

| 26 – 48 | 0.8 – 1.0 | 3003, 3105 |

| 50 and above | 1.0+ | 5005, 3105 |

The Applications of Aluminum Jacket in Pipe Systems

Aluminum jacketing ensures both insulation performance and mechanical protection.

Key Applications:

- HVAC ducts and pipes (indoor & outdoor)

- Petrochemical plants (oil, gas, refinery systems)

- Marine & offshore pipelines

- Power plants (steam and chilled water lines)

- Cold storage facilities (refrigeration ducts and piping)

Aluminum Roll Jacketing

Roll jacketing offers flexible length supply and is ideal for large projects. Rolls reduce material waste and improve installation speed.

Specifications of Aluminum Roll Jacketing:

| Width (mm) | Coil Weight (kg) | Surface | Moisture Barrier |

|---|---|---|---|

| 914 | 50 – 500 | Smooth, Stucco, Corrugated | Polykraft, PVDF |

| 1000 | 100 – 1000 | Smooth, Stucco, Corrugated | Polykraft, PVDF |

| 1219 | 200 – 1500 | Smooth, Stucco, Corrugated | Polykraft, PVDF |

What is Aluminum Jacketing?

Aluminum jacketing is a thin, durable sheet of aluminum specifically designed to cover and protect insulation materials. Its primary function is to extend the life of insulation systems by providing a weatherproof and damage-resistant exterior. It’s lightweight, easy to install, and offers excellent corrosion resistance, making it an ideal choice for diverse environments, from indoor industrial settings to harsh outdoor conditions.

Why Choose Our Aluminum Jackets?

- 20 years of manufacturing experience

- ISO 9001 certified quality system

- Custom sizes and specifications available

- Competitive prices with fast delivery

- Technical support for installation guidance

FAQ – Frequently Asked Questions

Q1: What is aluminum jacketing used for?

It is used to protect duct and pipe insulation from weather, moisture, and mechanical damage.

Q2: Which thickness should I choose?

- Small ducts: 0.3–0.5 mm

- Standard pipes: 0.5–0.7 mm

- Outdoor heavy-duty: 0.8–1.0+ mm

Q3: Can aluminum jacketing be painted?

Yes, alloys like 3105 and 3003 can be coated with PVDF or polyester paint.

Q4: Is aluminum jacketing rust-proof?

Yes, aluminum is naturally corrosion resistant, especially alloys 3003 and 5005.

Q5: What are common sizes?

- Sheets: 4×8 ft

- Coils: 914 mm, 1000 mm, 1219 mm width

- Thickness: 0.3 – 1.2 mm

Q6: Why choose factory supply?

Factory supply offers lower cost, quality control, and customized options.