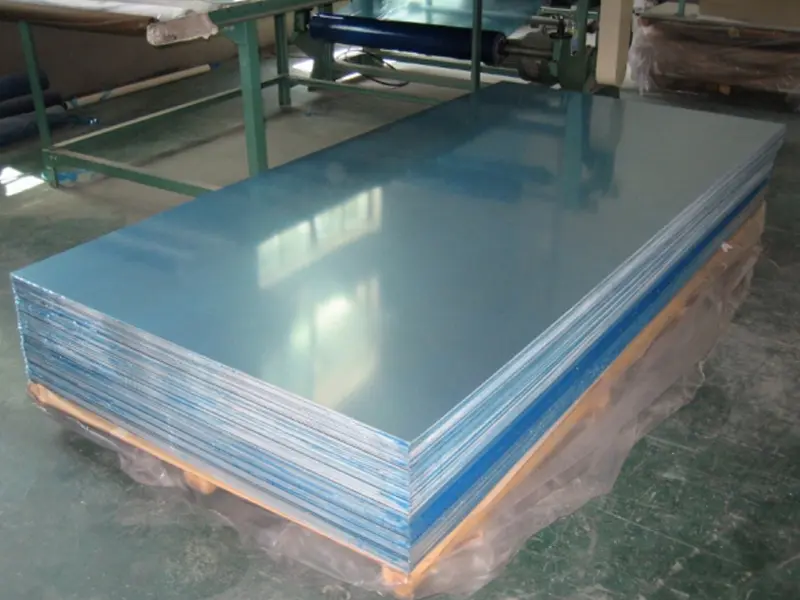

The 6063 aluminum sheet offers an excellent combination of formability, appearance, and corrosion resistance.

Whether you choose 6063-T52 for flexibility or 6063-T6 for strength, it’s perfect for architectural, marine, and industrial applications.

6063 Aluminum Sheet Suppliers

6063 aluminum sheet is a popular alloy in the Al-Mg-Si (aluminum-magnesium-silicon) family.

It’s known for excellent extrusion characteristics, smooth surface finish, and good corrosion resistance.

This alloy is widely used for architectural, decorative, and structural applications.

At WORTHWILL ALUMINUM, we supply 6063 aluminum sheets and plates in various tempers such as T5, T52, and T6, available in custom sizes and finishes.

| Specification | Detail |

|---|---|

| Alloy Type | 6063 (Al-Mg-Si) |

| Temper | O, T4, T5, T52, T6 |

| Thickness Range | 0.5 mm – 100 mm |

| Width Range | 1000 mm – 2000 mm |

| Length Range | 2000 mm – 6000 mm |

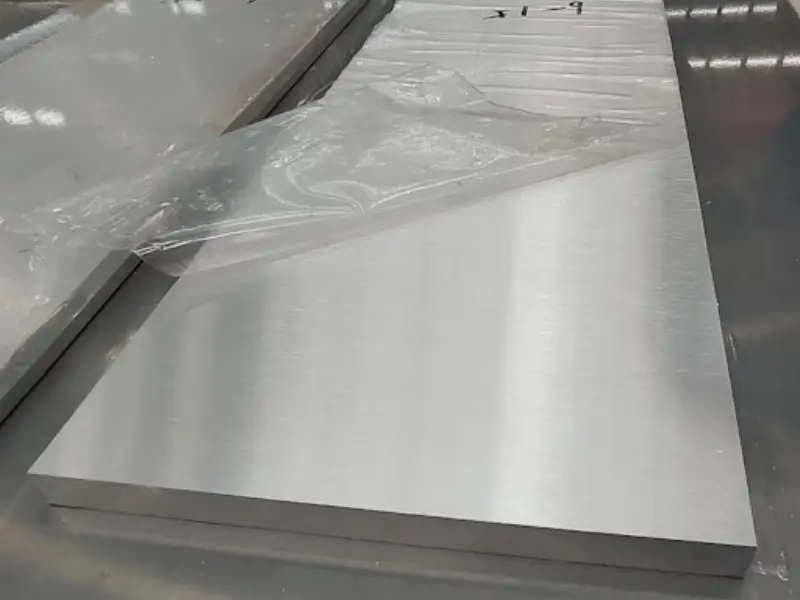

| Finish | Mill Finish, Anodized, Brushed, Painted |

6063-T52 Aluminum Properties

The 6063-T52 aluminum sheet is heat-treated and stress-relieved, offering moderate strength and excellent workability.

It is one of the most versatile materials for bending, forming, and anodizing.

| Property | Value |

|---|---|

| Tensile Strength | 190 MPa (27,500 psi) |

| Yield Strength | 145 MPa (21,000 psi) |

| Elongation | 8–10% |

| Density | 2.70 g/cm³ |

| Melting Point | 615°C |

| Thermal Conductivity | 201 W/m·K |

6063-T52 is ideal for curved or shaped profiles that need both appearance and function.

6063-T6 Aluminum

The 6063-T6 aluminum sheet is stronger than T52 due to artificial aging after heat treatment.

It combines good mechanical strength with excellent surface finish, making it suitable for load-bearing components.

| Property | 6063-T6 |

|---|---|

| Tensile Strength | 240 MPa (35,000 psi) |

| Yield Strength | 215 MPa (31,000 psi) |

| Brinell Hardness | 73 HB |

| Modulus of Elasticity | 68.9 GPa |

| Corrosion Resistance | Excellent |

6063 Aluminum Composition

The chemical composition of 6063 aluminum alloy determines its balance of strength and formability.

| Element | Content (%) |

|---|---|

| Aluminum (Al) | 97.5% – 99.0% |

| Magnesium (Mg) | 0.45% – 0.9% |

| Silicon (Si) | 0.2% – 0.6% |

| Iron (Fe) | ≤ 0.35% |

| Copper (Cu) | ≤ 0.10% |

| Manganese (Mn) | ≤ 0.10% |

| Chromium (Cr) | ≤ 0.10% |

| Zinc (Zn) | ≤ 0.10% |

| Titanium (Ti) | ≤ 0.10% |

This precise composition allows 6063 aluminum to achieve a smooth finish and good anodizing response.

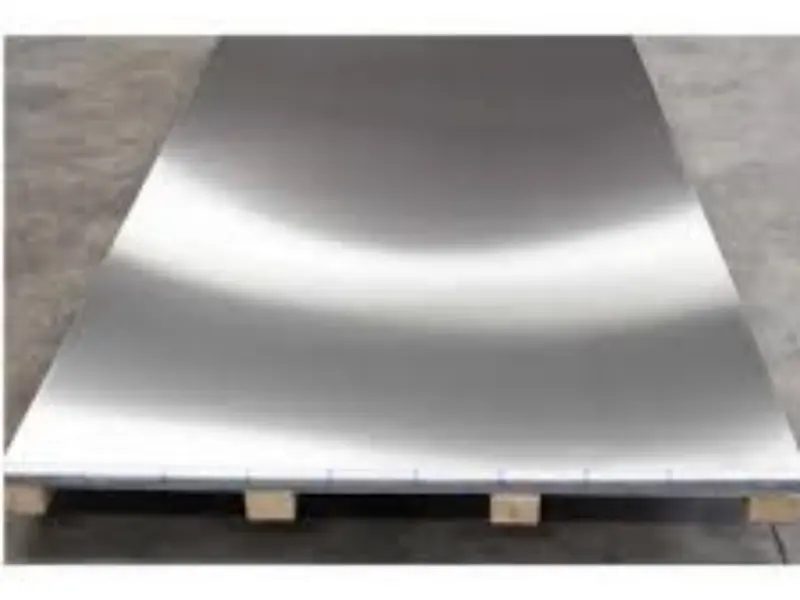

6063 Aluminum Bendable

One of the key advantages of 6063 aluminum is its excellent bendability and formability.

It can be easily bent, rolled, or formed into various shapes without cracking — especially in T4 or T52 temper.

Best tempers for bending:

- T4 → For deep bends and curves

- T52 → For standard forming

- T6 → For limited bending (may require heat assistance)

For tight bends, annealing or using a smaller temper like T4 is recommended.

6061 vs 6063 Aluminum

Both 6061 and 6063 belong to the same aluminum-magnesium-silicon series but serve slightly different purposes.

| Feature | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Strength | Higher | Moderate |

| Formability | Medium | Excellent |

| Surface Finish | Good | Very smooth |

| Machinability | Excellent | Good |

| Weldability | Excellent | Excellent |

| Common Use | Structural parts, frames | Architectural profiles, panels |

Choose 6061 for mechanical parts and 6063 for architectural or decorative uses.

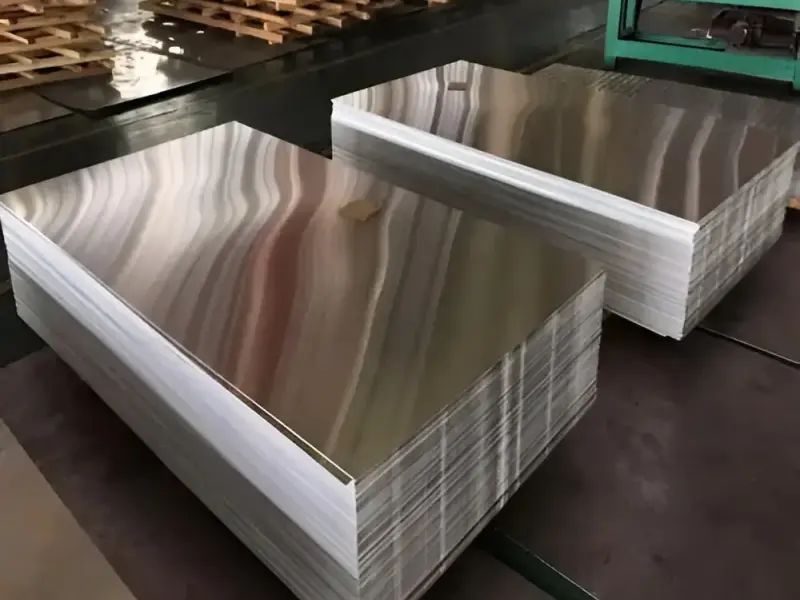

Aluminium Alloy 6063 Sheet Plate Sizes

6063 aluminum sheets and plates are available in different thicknesses and dimensions, suitable for both industrial and decorative projects.

| Thickness (mm) | Size (mm) | Weight (kg/m²) |

|---|---|---|

| 1.0 | 1000 × 2000 | 2.7 |

| 2.0 | 1220 × 2440 | 5.4 |

| 3.0 | 1500 × 3000 | 8.1 |

| 5.0 | 1500 × 3000 | 13.5 |

| 10.0 | 1500 × 3000 | 27.0 |

Custom sizes and cutting services are available from WORTHWILL ALUMINUM.

The Differences Between 6061, 6063, and 7075 Aluminum Sheet

| Alloy | Series | Strength | Corrosion Resistance | Weldability | Main Uses |

|---|---|---|---|---|---|

| 6061 | 6xxx | High | Very Good | Excellent | Frames, aircraft, tools |

| 6063 | 6xxx | Medium | Excellent | Excellent | Architectural, profiles |

| 7075 | 7xxx | Very High | Moderate | Poor | Aerospace, defense parts |

6063 offers the best mix of beauty and corrosion resistance, while 7075 is reserved for high-stress applications.

Applications of 6063 Aluminum Sheet

6063 aluminum sheets are used in various sectors due to their strength, smooth surface, and good formability.

Architecture

- Window and door frames

- Curtain walls and decorative panels

- Handrails and frames

Transportation

- Vehicle trims and panels

- Bicycle frames and luggage racks

- Marine fittings

Industrial Use

- Heat sinks and cooling components

- Electrical enclosures

- Machine covers and plates

Consumer Products

- Furniture

- Lighting frames

- Display fixtures

Advantages of 6063 Aluminum Sheet

- Smooth surface and easy to polish or anodize

- High corrosion resistance in outdoor environments

- Lightweight (density 2.7 g/cm³)

- Easy to cut, bend, and weld

- Suitable for both structural and decorative applications

FAQs about 6063 Aluminum Sheet

1. Is 6063 aluminum strong enough for structural use?

Yes, 6063-T6 provides moderate strength suitable for light structural applications.

2. Can 6063 aluminum be anodized?

Yes, it anodizes beautifully, producing a clean and bright surface.

3. What is the difference between 6063-T5 and 6063-T52?

T52 is stress-relieved and slightly softer, better for bending or shaping.

4. What thicknesses are available for 6063 aluminum sheets?

From 0.5 mm to 100 mm, with common sizes like 1mm, 2mm, 3mm, 5mm, and 10mm.

5. Where can I buy 6063 aluminum sheet?

You can purchase directly from WORTHWILL ALUMINUM, a professional aluminum sheet and plate manufacturer with full size and surface options.

6063 aluminum sheet Supplier

For competitive pricing and custom sizes, contact WORTHWILL ALUMINUM — your trusted 6063 aluminum sheet supplier with factory-direct service and fast delivery.