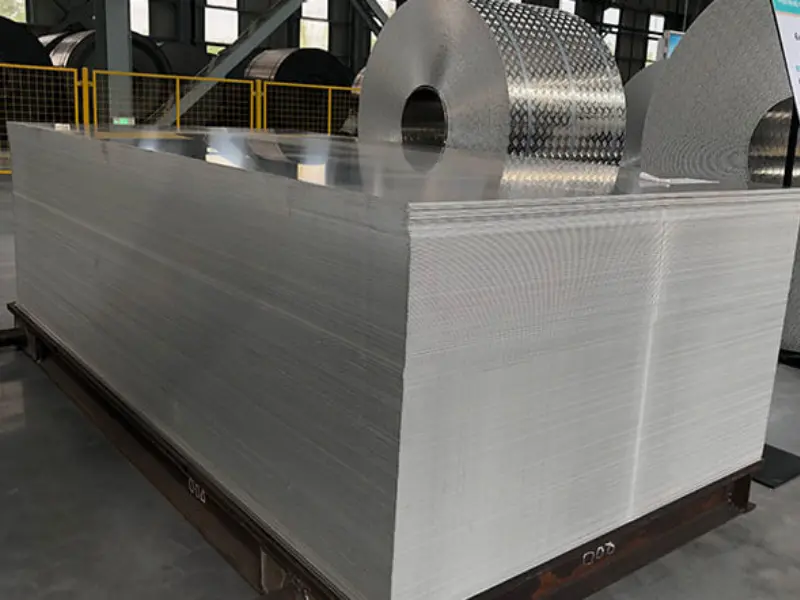

The 5052 H32 aluminum sheet is a reliable, all-purpose material for industrial and marine applications.

It combines medium strength, excellent corrosion resistance, and easy formability, making it one of the most widely used aluminum alloys.

For the latest 5052 aluminum sheet prices, custom sizes, and factory supply, contact Worthwill Aluminum — your trusted aluminum sheet and coil manufacturer in China.

5052-H32 vs 6061-T6 Aluminum

5052 H32 aluminum sheet is one of the most commonly used non-heat-treatable alloys. Compared to 6061-T6, 5052 offers better corrosion resistance, excellent formability, and smooth surface finish.

6061-T6, on the other hand, has higher strength but lower flexibility.

| Property | 5052-H32 Aluminum | 6061-T6 Aluminum |

|---|---|---|

| Temper | H32 (strain hardened, stabilized) | T6 (solution heat-treated) |

| Tensile Strength (MPa) | 215–265 | 290–320 |

| Corrosion Resistance | Excellent | Good |

| Formability | Excellent | Fair |

| Weldability | Good | Excellent |

| Typical Use | Marine, automotive panels | Structural parts, frames |

What is 5052 H32 Aluminum Sheet?

5052 H32 aluminum sheet is an alloy made of aluminum, magnesium (2.2–2.8%), and chromium (0.15–0.35%).

It is popular for high corrosion resistance, weldability, and moderate strength, making it suitable for marine and industrial use.

| Composition | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.40 |

| Silicon (Si) | ≤ 0.25 |

Key Features:

- Excellent resistance to saltwater and chemicals

- Easy to bend, form, and weld

- Smooth surface for painting or anodizing

- Lightweight (density: 2.68 g/cm³)

5053–5052 Aluminum Sheet Thickness

Although “5053” is sometimes mentioned, it’s likely a typo — 5052 is the correct alloy grade.

5052 aluminum sheet comes in various thicknesses to meet different project requirements.

| Common Thickness | Inch | Millimeter (mm) |

|---|---|---|

| 0.063″ | 1/16 | 1.6 mm |

| 0.090″ | 3/32 | 2.3 mm |

| 0.125″ | 1/8 | 3.2 mm |

| 0.190″ | 3/16 | 4.8 mm |

| 0.250″ | 1/4 | 6.4 mm |

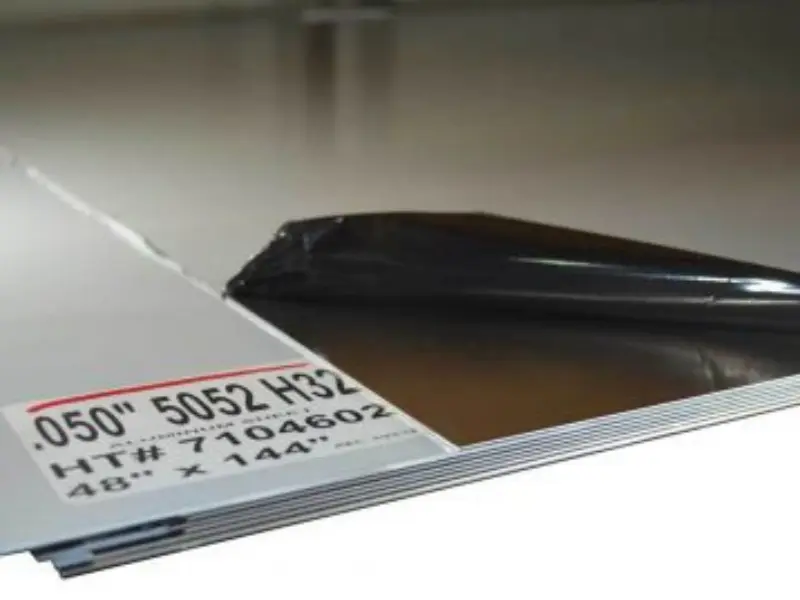

.090 Aluminum Sheet 4×8 and .090 5052 Aluminum Sheet

A .090″ 5052 aluminum sheet (4×8 feet) is a popular choice for general fabrication and marine applications.

This thickness provides a balance of strength and flexibility — easy to cut and bend while maintaining rigidity.

Typical Dimensions:

- Size: 4’ x 8’ (1220 mm x 2440 mm)

- Thickness: 0.090″ (2.3 mm)

- Weight: approx. 26 lbs (11.8 kg) per sheet

Uses:

- Truck panels

- Boat hulls

- Fuel tanks

- Signage and enclosures

.190 Aluminum Thickness and 13 Gauge Aluminum Sheet

The .190” thickness (about 3/16” or 4.8 mm) is a heavier option, used where more strength is needed.

13 gauge aluminum sheet is roughly equivalent to .090” thickness, often used for lighter structural parts.

| Gauge | Inch | mm |

|---|---|---|

| 13 | 0.090 | 2.29 |

| 11 | 0.125 | 3.18 |

| 7 | 0.190 | 4.83 |

5052 Aluminum Sheet: O Temper & H34 Sheet

5052 aluminum sheets are available in several temper options:

| Temper | Description | Features |

|---|---|---|

| O (Annealed) | Soft, easily bent | Best for deep drawing or spinning |

| H32 | Half-hard, stabilized | Common industrial grade |

| H34 | Slightly harder | Higher strength with fair formability |

| H36 | Hard | Increased stiffness and strength |

Each temper serves different fabrication needs — O for flexibility, H34/H36 for strength.

What Is the Difference Between 6061 and 5052 H32 Aluminum?

The main differences are mechanical strength and corrosion resistance:

- 6061: Stronger, ideal for structural and load-bearing parts

- 5052: More corrosion-resistant, ideal for marine and chemical environments

- Weldability: Both are weldable, but 5052 offers smoother weld finish

- Surface: 5052 provides a better anodizing surface for decorative purposes

How Much Is a Sheet of 5052 Aluminum?

The price of 5052 H32 aluminum sheet depends on thickness, size, and market conditions.

As a reference:

| Thickness (inch) | Size (ft) | Weight (kg) | Approx. Price (USD/kg) |

|---|---|---|---|

| 0.063 | 4×8 | 8.5 | $3.20 – $3.80 |

| 0.090 | 4×8 | 11.8 | $3.10 – $3.70 |

| 0.125 | 4×8 | 15.6 | $3.00 – $3.60 |

(Prices vary daily; contact Worthwill Aluminum for latest quotation.)

What Is the Difference Between 5052 O and 5052 H32?

- 5052-O is fully annealed, soft, and very easy to form.

- 5052-H32 is strain-hardened and stabilized — stronger but slightly less bendable.

| Property | 5052-O | 5052-H32 |

|---|---|---|

| Hardness | Soft | Medium |

| Formability | Excellent | Good |

| Tensile Strength | 28,000 psi | 33,000 psi |

| Applications | Deep drawing, spinning | Marine, enclosures, panels |

Applications of 5052 H32 Aluminum Sheet

5052 aluminum is versatile and used across many industries:

- Marine: boat hulls, deck panels, and fuel tanks

- Transportation: truck beds, bus panels, and trailers

- Construction: roofing, signage, and wall panels

- Industrial: enclosures, equipment housings, machine parts

- Consumer Goods: cabinets, kitchen appliances, decorative trims