5052 H32 aluminum is one of the most widely used aluminum alloys. It offers excellent corrosion resistance, medium strength, and great workability. This alloy is especially suitable for marine environments, construction, automotive parts, and industrial applications.

Classification

5052 H32 aluminum can be classified based on product form and application:

| Classification | Description |

|---|---|

| Aluminum Sheet | Flat plates for construction, panels, covers |

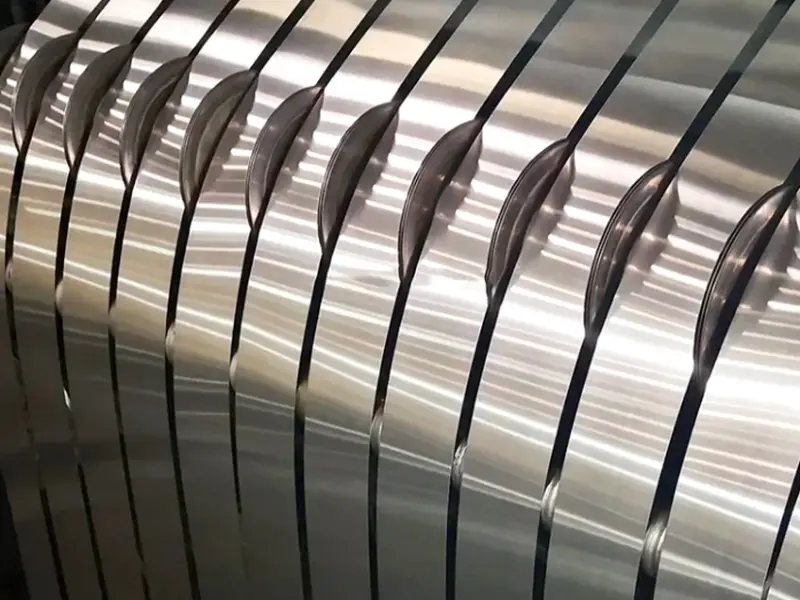

| Aluminum Coil | Rolled coils for roofing, siding, packaging |

| Aluminum Strip | Narrow cut coils for cable, electrical, and sealing use |

| Aluminum Plate | Heavy gauge panels for marine and structural use |

| Customized Profiles | Tailored designs for industrial projects |

Thickness

| Thickness (mm) | Common Application |

|---|---|

| 0.2 – 0.5 mm | Roofing, signage, packaging |

| 0.5 – 1.5 mm | Automotive panels, enclosures, electronics |

| 1.5 – 3.0 mm | Construction facades, marine panels |

| 3.0 – 6.0 mm | Structural parts, heavy-duty equipment |

| 6.0 – 10.0 mm | Shipbuilding, aerospace, pressure vessels |

Alloy Information

| Alloy | Temper | Characteristics |

|---|---|---|

| 5052 | H32 | Medium strength, excellent corrosion resistance, good welding performance |

Key features of 5052 H32 aluminum:

- Density: 2.68 g/cm³

- Tensile strength: 210–260 MPa

- Elongation: ≥ 7%

- Excellent resistance to saltwater and chemicals

Types

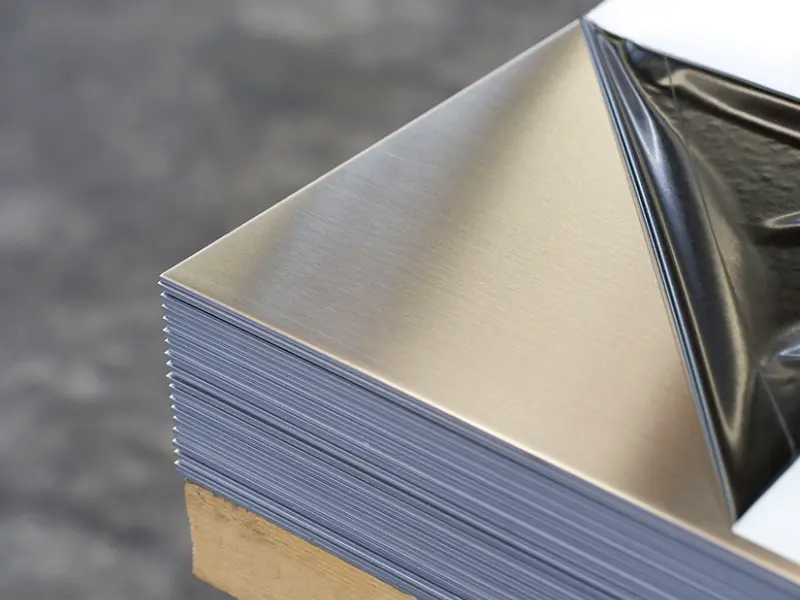

Mill Finish Sheet/Coil

The mill finish 5052 H32 aluminum sheet or coil has a standard surface that is smooth and clean. It is mainly used for further processing such as cutting, bending, or coating.

Anodized Aluminum

Anodized 5052 H32 aluminum offers enhanced corrosion resistance and a bright decorative appearance. This type is ideal for marine projects, architecture, and outdoor applications where durability is important.

Painted / Color Coated Aluminum

Painted or color coated aluminum with PVDF or PE layers provides strong weather protection and long-lasting colors. It is suitable for cladding, curtain walls, ceilings, and advertising panels.

Embossed Aluminum

Embossed 5052 H32 aluminum comes with stucco or diamond patterns. Its textured surface adds slip resistance, making it useful for flooring, stair treads, and anti-slip platforms.

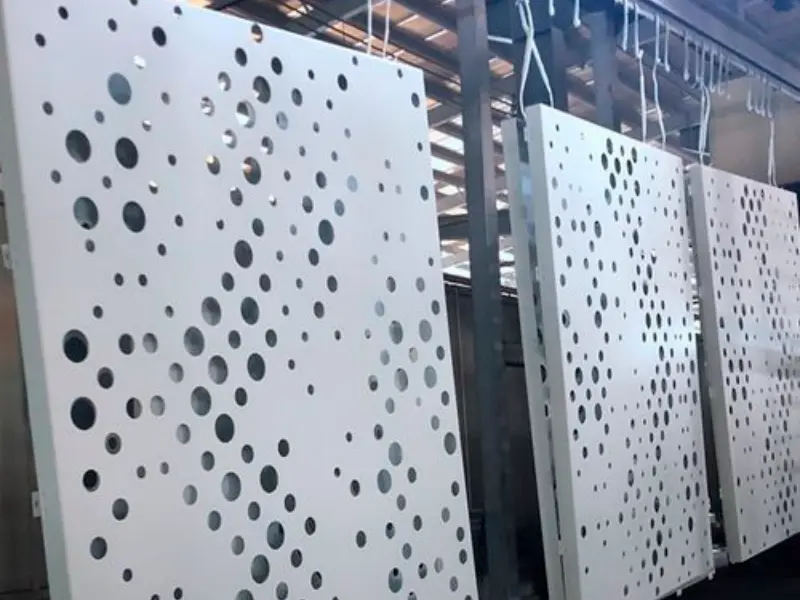

Perforated Aluminum

Perforated 5052 H32 aluminum features evenly distributed holes for ventilation, decoration, and filtration. It is widely used in acoustic panels, machine guards, and decorative facades.

Choosing the Right 5052 H32 Aluminum Sheet

When selecting 5052 H32 aluminum sheet for your project, consider these key factors:

- Application Environment: For highly corrosive environments like marine, 5052 is an excellent choice.

- Required Strength and Formability: The H32 temper offers a good balance.

- Thickness: Match the thickness to the structural and weight requirements of your design.

- Dimensions: Ensure the available width and length fit your cutting and fabrication needs to minimize waste.

- Surface Finish: Decide if a standard mill finish is acceptable, or if a polished or anodized surface is required for aesthetic or additional protection reasons.

Always consult with a reputable supplier or 5052 aluminum sheet factory to ensure you get the exact specifications for your unique project.

5052 H32 Aluminum Sheet Factory & Manufacturing Process

A modern 5052 aluminum sheet factory employs advanced technology to produce high-quality sheets. The general manufacturing process involves several precise steps:

Quality Control: Throughout the entire process, strict quality checks to ensure the 5052 aluminum sheet meets industry standards for chemical composition, mechanical properties, dimensions, and surface quality.

Melting and Casting: Raw aluminum ingots and alloying elements (like magnesium) are together in a furnace.

Hot Rolling: The ingots are through a hot rolling mill, which reduces their thickness and forms a continuous slab.

Cold Rolling: This process refines the grain structure and increases the material’s strength.

Strain Hardening & Stabilization: To achieve the H32 temper, the 5052 aluminum sheet undergoes a controlled amount of cold working (strain hardening) to reach a quarter-hard condition.

Finishing: The sheet is then leveled, trimmed to desired widths, and cut into specific lengths, or coiled.

Packaging

Proper packaging ensures safety during transport:

- Protective plastic film on surface

- Wooden pallets or cases

- Waterproof wrapping for marine shipping

- Clear labeling of alloy, temper, thickness, and lot number

Applications

- Marine Industry: ship hulls, decks, tanks, offshore structures

- Automotive: fuel tanks, panels, covers

- Construction: facades, roofing, ceilings, panels

- Electrical & Electronics: enclosures, heat exchangers, cables

- Industrial Equipment: pressure vessels, pipelines, storage tanks

- Household Products: kitchen appliances, utensils, decorative panels

FAQ

1. What does 5052 H32 mean?

5052 is the alloy number, and H32 is the temper, meaning strain-hardened and stabilized.

2. Is 5052 H32 aluminum good for welding?

Yes, it has excellent welding performance with both TIG and MIG methods.

3. What thicknesses are available?

From 0.2 mm up to 10 mm, depending on application.

4. Can 5052 H32 aluminum be anodized?

Yes, it anodizes well and gives a bright, durable surface.

5. What industries use 5052 H32 the most?

Marine, automotive, construction, and industrial equipment.

6. How is it packaged for export?

Standard export wooden pallets with protective wrapping and labeling.

Others

Q: What makes 5052 H32 aluminum sheet so good for marine environments?

A: Its high magnesium content provides exceptional resistance to corrosion from saltwater, making it ideal for boat hulls, fuel tanks, and other marine components.

Q: Can 5052 H32 aluminum sheet be welded easily?

A: Yes, 5052 aluminum sheet has good weldability. It’s commonly welded using inert gas welding methods (MIG or TIG), often with 5356 filler wire to ensure the best joint strength and corrosion resistance.

Q: Is 5052 H32 magnetic?

A: No, like all aluminum alloys, 5052 aluminum sheet is non-magnetic. This property can be important for certain electronic or sensitive equipment applications.

Q: What does the “H32” temper signify in 5052 H32?

A: This process gives it a balanced combination of strength, ductility, and formability, making it easier to work with than a fully hard temper.

Q: How does 5052 H32 compare to other common aluminum alloys like 6061 T6?

A: 5052 offers superior corrosion resistance, especially in saltwater, and better formability than 6061 T6. While 6061 T6 is stronger and often preferred for heavy structural applications that require heat treatment, 5052 excels where excellent corrosion resistance and good workability are primary concerns.