In recent years, the domestic and foreign markets favor hot rolled aluminum circle. The 5052 aluminum circle is one of the best. 5052 alloy belongs to the 5000 series. the main metal elements are Al and Mg. In addition, 5052 alloy has medium strength, high fatigue strength, high plasticity and corrosion resistance, good weldability, poor machinability, and can be polished.

5052 Aluminum Circle Specifications

| Specification | Details |

|---|---|

| Alloy | 5052-H32 / H34 / O |

| Thickness Range | 0.5 mm – 6.0 mm |

| Diameter Range | 100 mm – 1200 mm |

| Shape | Round (Blank / Disc) |

| Finish | Mill finish, anodized, or coated |

| Standards | ASTM B209, ISO, RoHS compliant |

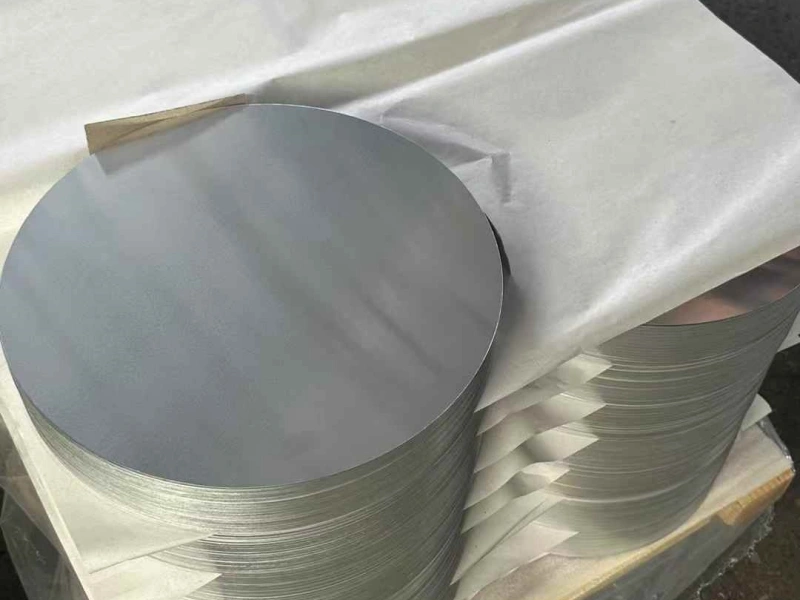

| Surface Quality | Smooth surface, no cracks or spots |

Custom thickness and diameter are available on request.

5052 aluminum circle advantage

- Mediumstrength aluminum alloy, low density, strength higher than 1, 3 series aluminum alloy

- Good plasticity, excellent forming effect, easy to process

- Good fatigue performance, welding performance, strong resistance to Marine atmospheric corrosion.

- Excellent reflectivity, good for Polishing.

- Clean surface and smooth edge, hot rolled quality, fine grains and after deep drawing no looper lines.

5052 vs. Other Aluminum Alloys

| Property | 5052 | 3003 | 6061 |

|---|---|---|---|

| Strength | Medium | Low | High |

| Corrosion Resistance | Excellent | Good | Good |

| Formability | Excellent | Excellent | Fair |

| Weldability | Good | Good | Excellent |

| Best For | Marine, Cookware | General Use | Structural |

Product details

| Alloy | 5052 |

| Temper | O, H12, H14, H16, H18, H32, H34, H111 |

| Thickness | 0.2-6mm |

| Diameter | 50-2200mm |

| Color | aluminum natural color |

5052-H32 vs. H34 Aluminum Circles: Which One Fits Your Project?

Need durable, corrosion-resistant aluminum discs? Both 5052-H32 and H34 aluminum circles deliver exceptional performance, but their unique properties cater to different needs. Here’s how to choose:

Key Differences at a Glance

| Property | 5052-H32 | 5052-H34 |

|---|---|---|

| Strength | Medium | Higher |

| Formability | Better | Good |

| Ideal For | Cookware, Lighting, Marine Trim | Heavy-Duty Parts, Structural Components |

| Price | More Budget-Friendly | Slightly Higher |

Why Choose 5052-H32?

✔ Best for Spinning & Deep Drawing – Softer temper, perfect for cookware and LED reflectors.

✔ Cost-Effective – Great balance of strength and affordability.

✔ Marine-Grade Resistance – Handles saltwater environments with ease.

Why Choose 5052-H34?

✔ 20% Stronger Than H32 – Handles heavier loads (e.g., automotive brackets, industrial parts).

✔ Retains Corrosion Resistance – Still excels in harsh conditions.

✔ Holds Shape Better – Less risk of deformation under stress.

Popular Applications

- H32: Pots/pans, lighting fixtures, decorative panels.

- H34: Boat components, truck parts, machinery shields.

5052 aluminum circle application

5052 Aluminum circle have good plasticity and weldability, so they are widely used in various fields. Here are some of its common uses:

Cookware

With the continuous improvement of economic and social development level, people’s material life starts to improve. People’s requirements for kitchenware are not only to be able to use, but to be convenient and beautiful.

Because of its light material and corrosion resistance, 5052 aluminum circle have wide applocations to make non-stick cookers, pressure cookers, kitchenware and so on.

5052 aluminum circle surface after special treatment of film thickness suitable, stable performance, can recycling. At the same time, the 5052 aluminum circle looks beautiful and is suitable for modern kitchen style.

Hardware supplies

Many common hardware supplies in life are made of 5052 aluminum circle. Such as lampshades, lamps, water heater shells, glass window locks, and some capacitor aluminum shells. This is because the aluminum circle has excellent corrosion resistance and malleability. So it can be made into the required shape according to demand, to meet the design needs of many lamps and lampshades. After secondary processing of aluminum discs can made into a variety of electrical enclosures, especially suitable for hardware industry applications.

Household appliance

Househol d appliances are essential daily necessities for every household. It not only needs to be beautiful and durable, but also needs to have high reliability. The 5052 aluminum circle meets these characteristics. Moreover, aluminum has good heat dissipation and thermal conductivity, therefore, electric kettle thermal chassis, rice cooker liner and a variety of thermal components often use 5052 aluminum circle.

What’s the difference between 5052 and 3003 aluminum?

- Different chemical compositions.3003 aluminum is aluminum-manganese alloy, the main alloy element is manganese. 5052 aluminum is aluminum-magnesium alloy, the main alloy element is magnesium.

2. Price is different. The price of one ton of 5052 aluminum is higher than the price of one ton of 3003 aluminum.

Aluminum circle production process

Aluminum Ingot/Master Alloys — Aluminum Melting Furnace — Aluminum Slab — Hot Rolling (Direct Cast) Or Cold Rolling (Cold Cast) — Punching — Annealing Furnace — Final Inspection — Packing

Why choose Worthwill aluminum circle

- Henan Worthwill Industry Co., Ltd has a long history, with professional technical personnel and experienced sales personnel. They can solve various problems and give professional purchasing advice.

- Have standard inspection procedures to ensure product quality.

- Our products comply with ASTM-B209 and GBT3880-2006, and have obtained ISO9001 certification.

- Product specifications are complete and customization is accepted.

- We provide free samples.

- Our products have been exported to the UAE, Australia, Canada, Mexico and other countries many times. we have rich export experience.

Outstanding Properties of 5052 Aluminum

Excellent Corrosion Resistance

One of the most significant benefits of the 5052 aluminum circle is its strong resistance to corrosion. This alloy forms a natural, protective oxide layer on its surface. This layer prevents rust and damage from chemicals, saltwater, and humidity. This feature makes 5052 aluminum ideal for outdoor products and items exposed to wet or salty conditions.

Superior Formability

5052 aluminum is perfect for processes like deep drawing, spinning, and stamping. This makes the aluminum disc a flexible material for manufacturers who need to create complex shapes from a flat circular piece.

Good Strength-to-Weight Ratio

Despite being lightweight, the 5052 aluminum circle offers good strength. This high strength-to-weight ratio is a major advantage. Products made from 5052 aluminum are easy to handle and transport, while still being strong enough for their intended purpose. This lightness can also save on energy costs in applications like transportation.

Strong Weldability

The 5052 aluminum alloy allows manufacturers to join different pieces of aluminum circle together or combine them with other aluminum components, creating larger or more complex structures.

Versatile Applications of 5052 Aluminum Circle

Here are some common applications:

- Cookware: Many pots, pans, and other kitchen utensils are made from 5052 aluminum circles. Its excellent thermal conductivity and ease of shaping make it ideal for heat distribution and durable kitchenware.

- Road Signs and Traffic Signs: Due to its resistance to weathering and corrosion, 5052 aluminum is a preferred material for road and traffic signs. They withstand rain, sun, and temperature changes without rusting.

- Lighting Fixtures: From outdoor lamps to internal light fittings, the lightweight and formable nature of aluminum circles makes them perfect for creating various lighting designs.

- Pressure Vessels: The strength and corrosion resistance of 5052 aluminum make it suitable for manufacturing small pressure vessels and tanks.

- Automotive Parts: Certain components in vehicles, especially those requiring good formability and corrosion resistance, use 5052 aluminum.

- Building Materials: In construction, 5052 aluminum circles can be used for decorative elements, roofing parts, or other architectural features.

- Electronic Housings: Its ability to dissipate heat and its light weight make it a good choice for covers and housings for electronic devices.

Why Choose 5052 Aluminum Circle for Your Project?

Choosing the 5052 aluminum circle for your manufacturing needs offers many benefits. Its ease of processing means faster production times and more complex designs are possible. For products that need to look good and last long, whether indoors or outdoors, the 5052 aluminum circle is an excellent investment. Its environmental benefits, being a highly recyclable material, also add to its appeal for sustainable manufacturing practices.

Manufacturing Process of Aluminum Circles

The creation of an aluminum circle typically starts with a large sheet of 5052 aluminum alloy. This sheet undergoes a process of cutting or punching. This process ensures consistent quality and exact dimensions for each aluminum disc, making them ready for immediate use in production lines.

Packing&delivery

- International Standard Seaworthy Packaging wooden pallets/Skids/Cases/Boxes

- Delivery time: 15-35 days after receiving the LC or 30% deposit.

Frequently Asked Questions (FAQ)

What is the main difference between 5052 and 1050 aluminum circles?

5052 has more strength and better corrosion resistance compared to 1050, which is softer and more ductile. 5052 is ideal for more demanding applications.

Can 5052 aluminum circles be used for deep drawing?

Yes, 5052-O temper in particular is suitable for deep drawing and other forming operations.

What is the minimum order quantity (MOQ)?

We support small batch orders, with MOQs as low as 500 kg, depending on the size.

Do you offer customized cutting

Yes! We offer CNC circle cutting, blanking, and edge processing to meet exact customer specifications.

Are samples available?

Yes. We provide free samples (A4-size or small blanks) for quality testing—shipping cost covered by the buyer.

📞 Contact Us for 5052 Aluminum Circle Price

Looking for a trusted supplier of 5052 aluminum circles?

📧 Email: jane@wwaluminum.com

📱 WhatsApp: +86 15736973771

🌐 Website: www.wwaluminum.com

Get a free quote, samples, or production lead time today. We’re happy to support your project!