3003 Aluminum Circle

A 3003 aluminum circle refers to a circular piece of aluminum that is made from the alloy 3003.

The 3003 aluminum circle is a popular choice for many applications due to its corrosion resistance, ease of welding and forming, and affordable cost.

Application

3003 aluminum circle is a versatile material that can be used in various applications. Here are some common applications of 3003 aluminum circle:

Cookware: 3003 aluminum circle is widely in the production of cooking utensils such as pots, pans, and pressure cookers. Its excellent thermal conductivity and corrosion resistance make it a popular choice for cookware.

Lighting: To make reflectors and lampshades for various lighting applications. Its high reflectivity and low density make it an ideal material for these applications.

Signage: To make signs and nameplates for buildings, hotels, and offices. Its excellent corrosion resistance and formability allow it to be easily stamped or embossed with letters and designs.

Traffic signs: To make traffic signs due to its high reflectivity and durability.

Automotive: In the production of various automotive parts such as heat shields, fuel tanks, and radiator tanks.

Its excellent corrosion resistance and formability make it suitable for these applications.

Pressure vessels: To manufacture pressure vessels such as air receivers, gas cylinders, and hydraulic tanks.

Its high strength and corrosion resistance make it an ideal material for these applications.

Other applications: In the production of refrigeration equipment, chemical equipment, and other industrial applications.

3003 Aluminum Circle Specifications

| Property | Details |

|---|---|

| Alloy | 3003 Aluminum |

| Temper | O, H12, H14, H22, H24 |

| Diameter Range | 80 mm – 1200 mm |

| Thickness Range | 0.3 mm – 6.0 mm |

| Surface | Mill Finish, Anodized, Polished |

| Tolerance | ±0.01 mm |

| Packaging | Wooden Pallet, Standard Export |

Types of 3003 Aluminum Circle

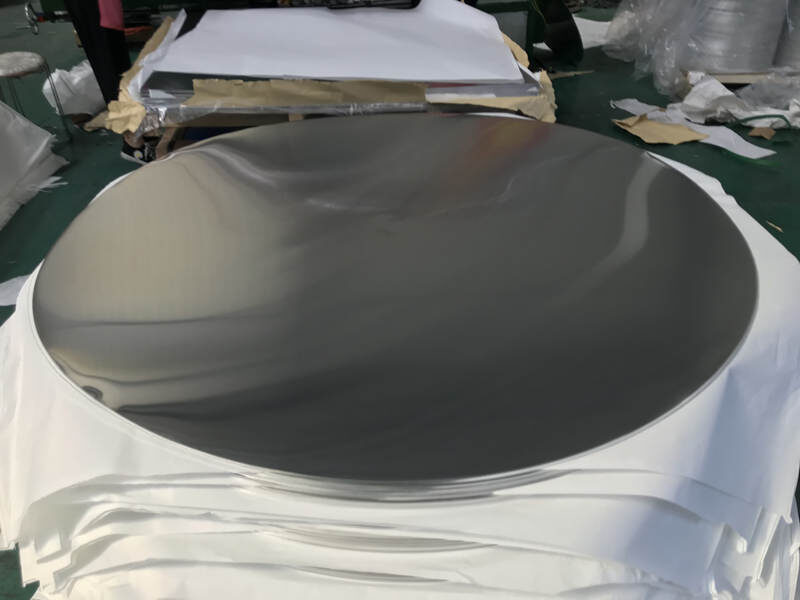

Mill Finish Aluminum Circle

-

Standard smooth surface

-

Ready for further processing or anodizing

Anodized Aluminum Circle

-

Enhanced corrosion resistance

-

Decorative surface options available

Polished Aluminum Circle

-

Mirror-like finish for cookware and decorative items

Coated Aluminum Circle

-

PE or PVDF coating for longer durability and color variety

The manufacturing process of aluminum circle

Melting: The first step in the process is to melt the aluminum alloy. This is typically done in a furnace or a melting pot.

Annealing: After rolling, the aluminum is annealed or heat-treated to increase its ductility and reduce its brittleness. This process involves heating the aluminum to a specific temperature and then cooling it slowly.

Punching: It is ready to be punched into a circular shape. The punching process involves using a die or a mold to stamp out the circle shape from the aluminum sheet.

Finalizing: The final step involves any necessary finishing touches such as cutting the circle to the final size, polishing or sandblasting the surface, or applying any coatings or finishes that may be required for the intended application.

Overall, the manufacturing process for aluminum circle is a precise and detailed process that requires careful attention to detail to produce a high-quality product.

3003 Aluminum Circle for Cookware and Industrial Use

The 3003 aluminum circle is one of the most popular materials for manufacturing cookware, lamps, and industrial components. Known for its excellent corrosion resistance, high formability, and smooth surface, it is widely used in deep drawing and spinning processes. Customers choose 3003 aluminum discs because they combine durability with cost-effectiveness.

Why Choose 3003 Aluminum Circle?

When compared with other alloys, 3003 aluminum circle provides:

-

Excellent corrosion resistance, even in humid or chemical environments

-

Lightweight properties with strong mechanical strength

-

Smooth surface finish suitable for anodizing or coating

-

High plasticity, making it ideal for deep drawing and spinning

-

Long service life, reducing replacement costs

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The Difference Of 1050 and 3003 Aluminum Circle

1050 and 3003 are two commonly alloys for making circular aluminum discs or circles. Here are some of the main differences between the two:

Alloy composition: 1050 contains 99.5% aluminum, while 3003 aluminum circle contains 96.7% aluminum and 1.2% manganese. The additional manganese in 3003 provides better strength and corrosion resistance than 1050.

Mechanical properties: 3003 has higher tensile strength and better elongation than 1050. It more durable and better suited for applications that require more strength and flexibility.

Formability: Both 1050 and 3003 are highly formable and easy to work with, but 3003 is more ductile and can be formed into more complex shapes than 1050.

Corrosion resistance: Both 1050 and 3003 have good corrosion resistance. But 3003 is more resistant to corrosion due to its higher manganese content.

Application: 1050 is commonly used in the manufacturing of lighting reflectors, cookware, and decorative parts due to its good reflectivity and formability.

Advantages of 3003 and 1050

3003 is commonly used in the manufacturing of pressure vessels, heat exchangers, and chemical equipment due to its higher strength and corrosion resistance.

In summary, 3003 aluminum circle is a stronger and more corrosion-resistant option than 1050. It a better choice for applications that require more strength and durability. However, 1050 is still a popular option for applications that require good formability and reflectivity.

What Is 3003 Alloy?

The alloy 3003 is a non-heat-treatable alloy that is commonly used in various applications such as cooking utensils, chemical equipment, and pressure vessels. It has good corrosion resistance and moderate strength, making it suitable for many different uses.

FAQ – 3003 Aluminum Circle

Q1: What is the main use of 3003 aluminum circles?

A: They are mainly used in cookware, lamps, and traffic signs due to their excellent formability.

Q2: Can 3003 aluminum discs be anodized?

A: Yes, 3003 alloy has a smooth surface that allows anodizing and coating.

Q3: What thickness range is available?

A: From 0.3 mm to 6 mm depending on your application.

Q4: Is 3003 aluminum suitable for deep drawing?

A: Yes, it is widely used in deep drawing cookware like pans and pots.

Q5: How is 3003 aluminum circle packaged for export?

A: Usually with wooden pallets, protective film, and standard export packing.