1060 Aluminum Circle

1060 aluminum circle belongs to 1000 series aluminum circle products. Aluminum circle, also known as aluminum disc, aluminum wafer, etc. And it’s one of the deep-processing products of the aluminum sheet plate. 1060 aluminum circle has many features that can meet the requirements of conventional processing.

| Alloy | 1060 |

| Temper | O, H12, H14, etc. |

| Thickness | 0.2-6.0mm |

| Technique | Hot rolled, cold rolled |

| Surface | Smooth and flat |

| Color | Silver or as request |

| MOQ | 3 tons |

| Service | Customize available |

| Thickness Range (mm) | Thickness Range (inches) | Typical Applications of 1060 Aluminum Circle |

|---|---|---|

| 0.2 – 0.5 | 0.008 – 0.02 | Bottle caps, thin foil containers, electrical capacitors, shallow drawn parts, food packaging. |

| 0.6 – 1.5 | 0.024 – 0.06 | Cookware (non-stick pans, baking trays), lighting reflectors, road signs, shallow stamping, general fabrication. |

| 1.6 – 3.0 | 0.063 – 0.12 | Deep drawing cookware (pressure cookers, large pots), traffic signs, general purpose deep drawing, spun parts. |

| 3.1 – 6.0 | 0.122 – 0.24 | Heavy-duty cookware bases, industrial components, thicker spun parts, certain automotive applications. |

Application

The versatility of 1060 aluminum circle makes it indispensable in a vast array of applications across numerous industries. Its formability, corrosion resistance, and conductivity are key factors.

Here are some popular application areas:

- Cookware: Pots, pans, pressure cookers, kettles, baking trays, and other kitchen utensils.

- Lighting Industry: Lamp shades, lighting reflectors, LED housing, downlights.

- Road and Traffic Signs: Due to its lightweight and good surface for painting or applying reflective sheeting.

- Bottle Caps and Closures: For beverages, pharmaceuticals, and cosmetics.

- Deep Drawing Parts: Components requiring significant forming, like certain automotive parts, capacitor shells.

- Electrical Components: Capacitor housings, busbars, and other parts where high electrical conductivity is needed.

- Building Materials: Some decorative elements and non-structural components.

- Heat Exchangers: Radiator fins, other heat dissipation components due to high thermal conductivity.

Features

- Wide range of circles’ size

- Excellent surface quality

- Excellent in forming, welding and corrosion resistance

- Superior thermal performance

- Excellent deep drawing and spinning quality

- Well protected packing

1060 Aluminum Circle Chemical Composition

Si : ≤ 0.25

Cu : ≤ 0.05

Mg : ≤ 0.03

Zn : ≤ 0.05

Mn : ≤ 0.03

Fe : ≤ 0.35

Ti : ≤ 0.03

V : ≤ 0.05

Other: ≤ 0.05

Others total: ≤ 0.15

Al ( Aluminum ): remainder

Key Temper Designations for 1060 Aluminum Circle

The “temper” of 1060 aluminum circle refers to its hardness or strength, which is controlled by cold working. Since 1060 is non-heat treatable, mechanical working is used to achieve different tempers.

Common tempers include:

- O (Annealed/Soft): This is the softest and most ductile temper, ideal for deep drawing, spinning, and forming complex shapes. It offers maximum workability.

- H12, H14, H16, H18, H22, H24, H26: These are various levels of strain-hardened (cold-worked) tempers. The higher the second number, the harder and stronger the material. For example, H18 is harder than H14. These tempers provide increased strength and stiffness while still maintaining good formability, though less than the O temper.

Choosing the right temper for your 1060 aluminum circle is crucial for successful manufacturing and product performance.

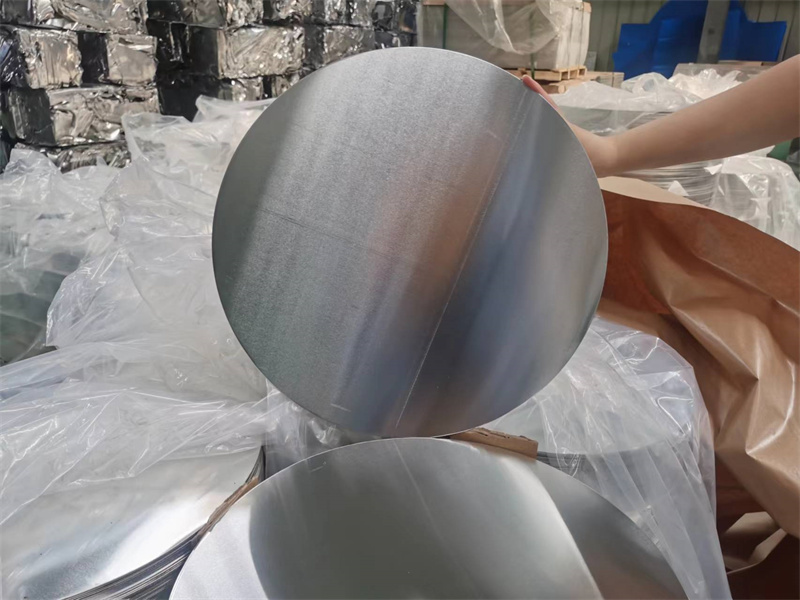

Packaging

1060 aluminum circle can be packed in export standard.

Firstly, covering with brown paper and plastic film. Then fixing the aluminium circle on wooden pallet or wooden case.

1060 Aluminum Circle Supplier

As a main supplier of aluminum circle, we adopt pure aluminum as material.

Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

WORTHWILL supplies the most extensive mill finish aluminum sheets and coils.

We support to customize according to customer requirement. Welcome new and old clients to contact us.

Aluminum Circle Factory

As a 10 years professional aluminum circle aluminum disc manufacturer, our aluminum circle is made with the best quality of the raw material and types of machinery.

And our company guarantees aluminum circle aluminum disc production and delivery days. More information, contact us freely.

1050 and 1060 Aluminum Disc Price

Overall, it really comes down to the purpose you plan on using the disc for.

If you’re looking to save some money while still getting some good materials and quality, go with the 1050.

However, if you’re looking for a disc that will last a long time with consistent maintenance, choose with the 1060.

What is 1060 Aluminum Circle?

1060 aluminum circle is a pure aluminum product with a minimum 99.6% aluminum content, known for its excellent formability, corrosion resistance, and electrical conductivity. These circular aluminum blanks are widely used in various industries for manufacturing products through deep drawing, spinning, and stamping processes.

Quality Control and Standards for 1060 Aluminum Circle

Ensuring the quality of 1060 aluminum circle is paramount for its performance in demanding applications. Manufacturers adhere to strict international standards such as ASTM (American Society for Testing and Materials) and EN (European Norms). Quality control measures typically include checks for chemical composition, mechanical properties (like tensile strength and elongation), surface finish, and dimensional accuracy (thickness and diameter tolerances). These rigorous checks guarantee that each 1060 aluminum circle meets the specified requirements and will perform reliably in its intended application.

Why Choose 1060 Aluminum Circle for Your Project?

Choosing a 1060 aluminum circle for your manufacturing needs means opting for reliability, workability, and cost-effectiveness. Its high purity ensures consistent performance in forming processes like deep drawing and spinning, leading to fewer defects and higher production efficiency. The natural corrosion resistance reduces the need for extensive surface treatments in many applications, saving time and money. Furthermore, its excellent conductivity makes it a safe bet for electrical and thermal management components. For projects prioritizing ease of fabrication and a balance of performance and price, 1060 aluminum circle consistently proves to be an outstanding material choice.

Technical Specifications

| Parameter | Standard Value | Testing Standard |

|---|---|---|

| Chemical Composition | Al 99.6% min, Fe 0.35% max, Si 0.25% max | ASTM B209 |

| Hardness (HV) | 20-30 | ASTM E10 |

| Flatness | ≤0.5mm/300mm | ASTM D1009 |

| Surface Roughness | Ra ≤0.4μm | ISO 4287 |

Quality Control Measures

Chemical Analysis: Verify aluminum purity and alloy composition

Dimensional Checks: Ensure thickness and diameter accuracy

Surface Inspection: Check for scratches, dents, or imperfections

Mechanical Testing: Verify tensile strength and elongation

Packaging Inspection: Ensure proper protection for shipment

Comparison with Other Aluminum Alloys

| Property | 1060 | 3003 | 5052 |

|---|---|---|---|

| Aluminum Content | 99.6% | 98.5% | 97.5% |

| Strength | Low | Medium | High |

| Formability | Excellent | Very Good | Good |

| Corrosion Resistance | Excellent | Very Good | Excellent |

| Cost | Low | Medium | High |

Manufacturing Process

Melting and Casting: Pure aluminum melted and cast into slabs

Hot Rolling: Slabs heated and rolled to intermediate thickness

Cold Rolling: Further reduction to required thickness

Circle Blanking: Precision punching of circles

Annealing: Heat treatment to achieve desired temper

Surface Treatment: Polishing or coating if required

Quality Inspection: Comprehensive testing and verification

Packaging: careful packaging for shipment

Why us?

- Top quality of aluminum circle

- Free samples for your reference

- Quick delivery on time

- Strict quality control system

- Comprehensive service

We have excellent aluminum circle price and quality.

If you have need, we provide free samples and customization service.

FAQ

Q: What is the maximum diameter available for 1060 aluminum circles?

A: Typically up to 1500mm, but custom sizes can be produced.

Q: Can 1060 aluminum circles be used for food contact applications?

A: Yes, 1060 aluminum is food-safe and commonly used in cookware.

Q: What is the difference between O temper and H14 temper?

A: O temper is soft and ideal for deep drawing, while H14 is harder and stronger.

Q: How does 1060 compare to other aluminum alloys for deep drawing?

A: 1060 offers excellent formability, better than most other alloys.

Q: Are custom sizes and thicknesses available?

A: Yes, manufacturers can produce custom specifications based on requirements.