Types And Functions Of Aluminum Trim Coil Colors

Aluminum trim coil is also known as coated aluminum coil. As we all know, the coil has a wide range of colors. Such as white, red, black, yellow and so on. There is a color card that contains all the colors of the aluminum ring. As long as you can accurately say the color number, or give the aluminum coil manufacturer a color sample, we can produce aluminum coils of the same color. So here comes the question, why we color the aluminum coil surface? Next let’s discuss.

Coating

Coating Technology: Powder Coated and Roller Coated

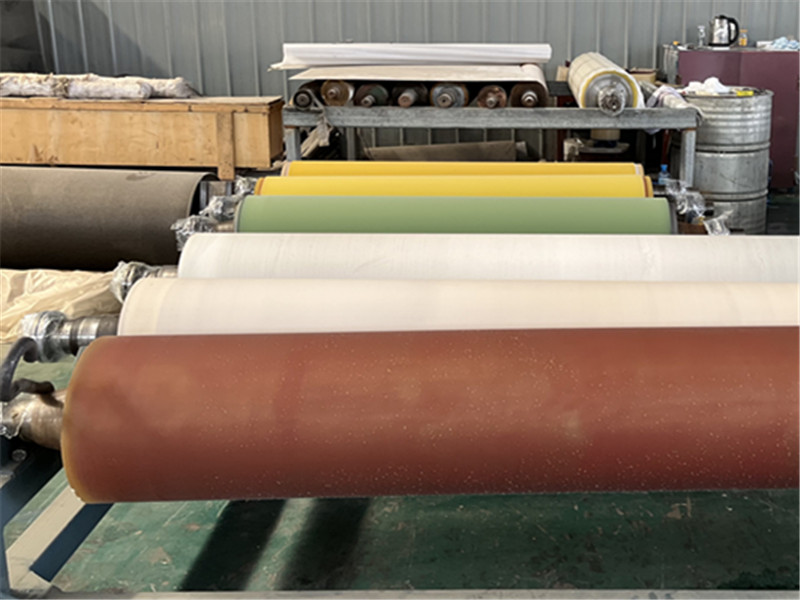

When we look at the color of the aluminum coil, it looks very beautiful and special. In order to color the coil surface, some manufacturers adopt powder coated technology and roller coated technology. Different coating technology has different features. For instance, compared with powder coated boards, the coating thickness of roll-coated boards is thinner.

Coating Types: PE and PVDF

PVDF and PE coating are the two most popular coatings. Both of them can add beautiful colors for aluminum coil. But, due to the different coating, the coil has different applications. For example, PVDF coated aluminum is suitable for exterior decoration, but PE coated aluminum is more suitable for interior decoration. In addition, PVDF coated aluminum coil has longer service life than PE coated aluminum coil.

Colors Functions

The color of the aluminum decorative trim coil is not only decorative, but also protective. The goal of the aluminum trim coil is to make it more attractive, more beautiful, and more creative space for designers of various end products. However, a more important function of color is to be protective. The color is usually PE or PVDF paint, the two most popular resin paints for metal decorative coils. These coatings are resistant to natural weather conditions such as sunlight, wind, rain, snow, frost and extreme temperatures, thus greatly extending the life of the coils.