Perforated Aluminum Sheet

Perforated aluminum sheets are versatile and widely for use materials in various industries due to their exceptional properties. The perforations has strategically placed to create a pattern of holes, offering unique design possibilities and functional advantages.

Applications across a wide range

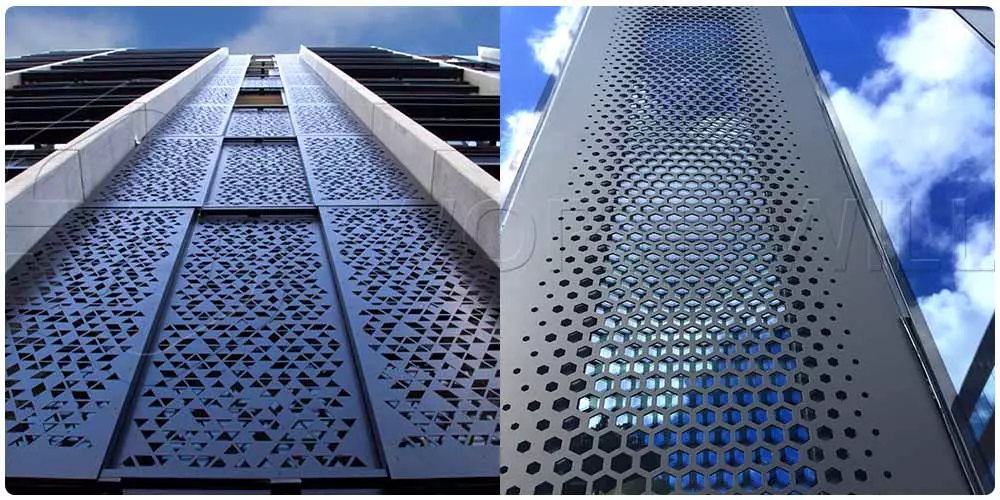

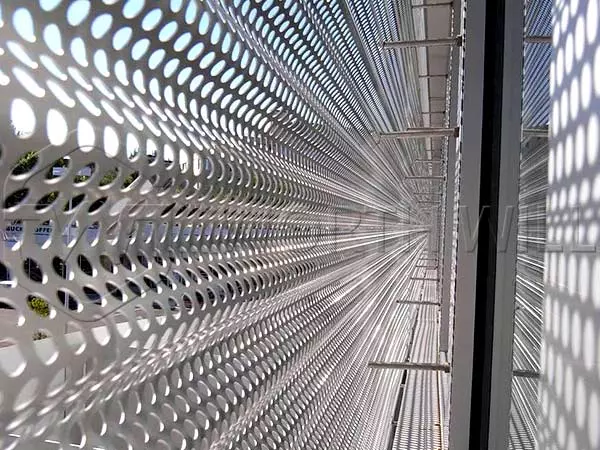

Architecture and Design: Extensively used in architectural projects for building facades, sunshades, cladding panels, interior design elements, decorative partitions, and more. They offer a combination of functionality, aesthetics, and creative possibilities.

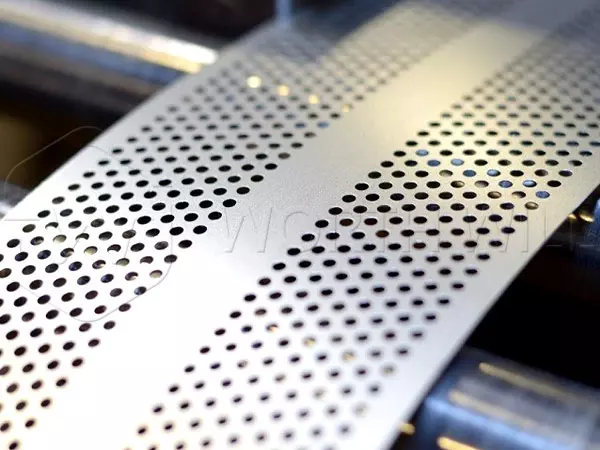

Industrial and Manufacturing: In industrial settings, perforated sheets are for filtration, screening, drying, separation, and conveying applications. They find usage in industries such as mining, agriculture, food processing, pharmaceuticals, petrochemicals, and many others.

Transportation: Employed in transportation sectors for manufacturing components. Such as grilles, air vents, speaker covers, and decorative panels. They provide airflow, structural support, and aesthetic appeal to automotive, aerospace, and marine applications.

Furniture and Interior Design: Utilized to create unique furniture pieces, room dividers, lighting fixtures, and acoustic panels. They contribute to the overall aesthetics and functionality of interior spaces. It offers design flexibility and customization options.

Benefits

Perforated aluminium sheets make them highly sought after in numerous applications. Some key features and benefits include:

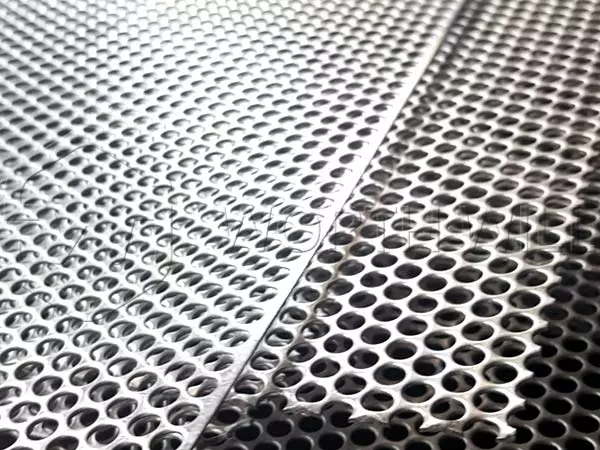

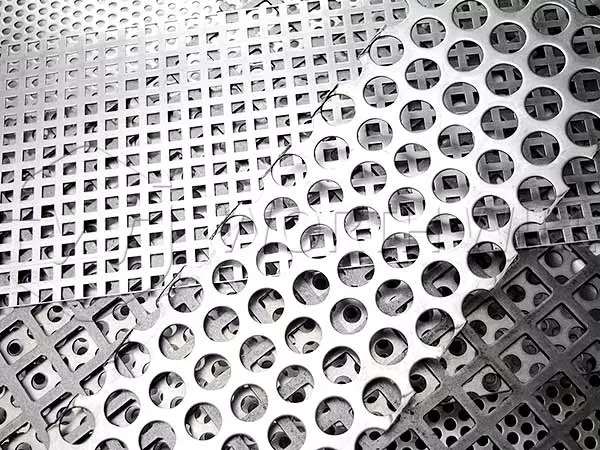

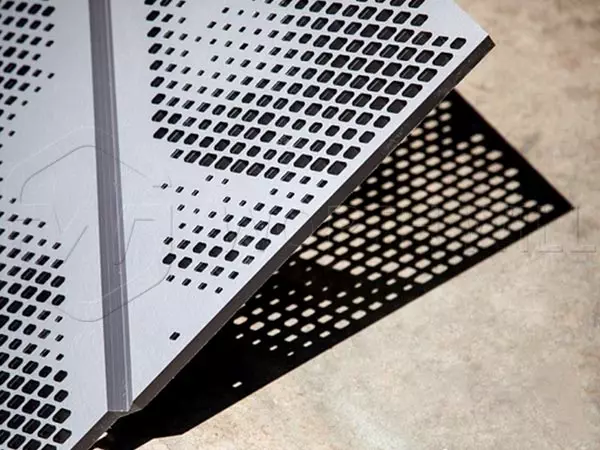

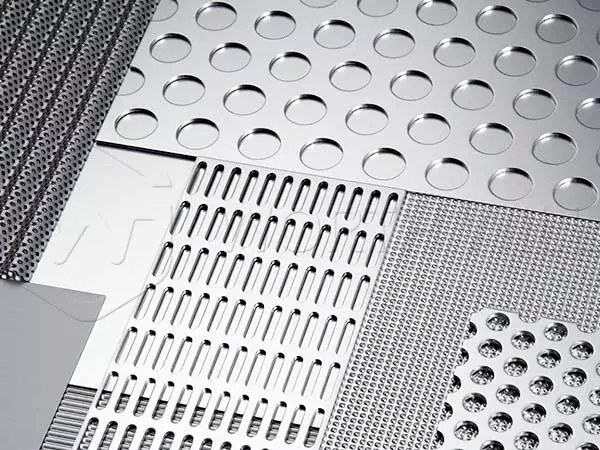

Versatility: Customized to meet specific design requirements, offering endless possibilities in terms of hole patterns, shapes, sizes, and open area percentages. This versatility allows for tailored solutions for different industries and applications.

Aesthetic Appeal: Provide a visually appealing element to architectural and design projects. They can be used to create unique patterns, textures, and visual effects, enhancing the overall aesthetics of a structure or product.

Enhanced Ventilation and Acoustics: Facilitate airflow and ventilation while also acting as sound absorbers. This makes them ideal for applications such as building facades, ceilings, and interior walls, where airflow and acoustic performance are essential.

Lightweight and Durable: Additionally, aluminum exhibits excellent durability, corrosion resistance, and weathering properties, ensuring longevity and low maintenance requirements.

Environmental Sustainability: A recyclable material, aligning with sustainable practices. Perforated aluminium sheets contribute to environmentally friendly design and construction solutions by reducing waste and promoting recyclability.

Manufacturing Process

The manufacturing process of perforated aluminum sheets involves several stages:

Material Selection: High-quality aluminum sheets with the desired properties are chosen for the perforation process.

Perforation: Specialized machinery, such as CNC punch presses, is used to create precise patterns of holes in the aluminum sheets. The hole size, shape, spacing, and open area percentage can be customized as per the requirements.

The Guide Of Purchase Perforated Aluminum Sheet

Welcome to the professional dedicated to perforated aluminium sheets. In this comprehensive guide, we will explore the various aspects of perforated aluminum sheets, including their features, applications, benefits, and manufacturing process.

Whether you are a design professional, architect, engineer, or simply someone interested in the field, this page aims to provide you with valuable insights into the world of perforated aluminum sheets.