PE Coated Aluminum

PE coated aluminum is an ideal material for building and construction industry. It provides excellent corrosion resistance, durability, and aesthetic finish to structural components, roofing systems, cladding, and panels.

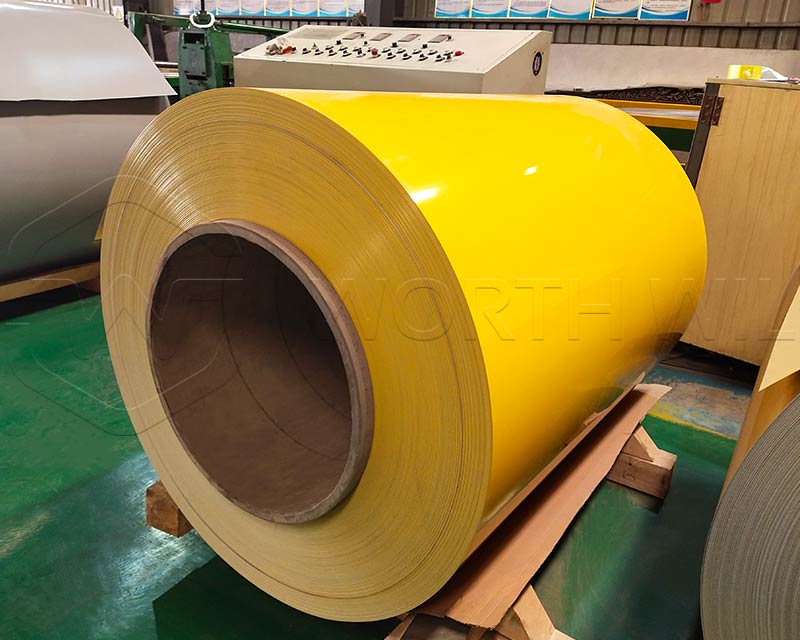

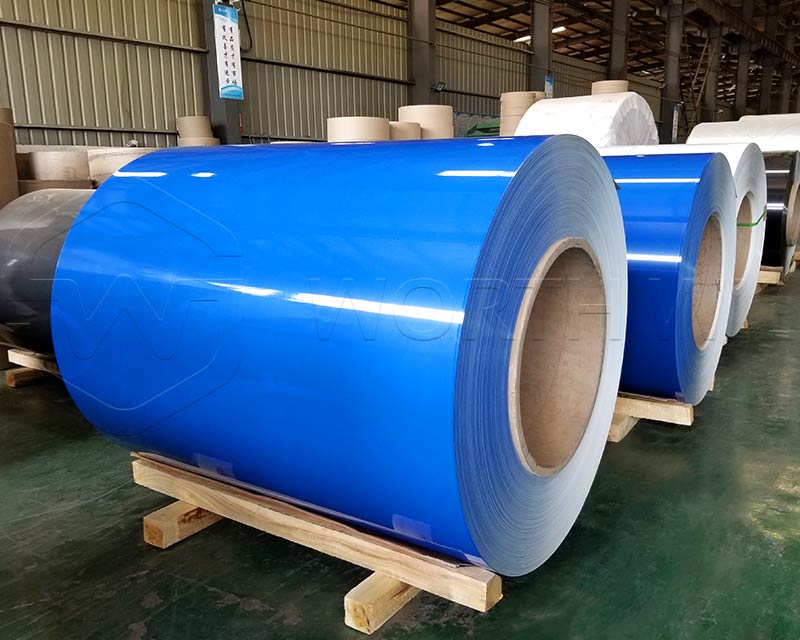

PE coated Aluminum Sheet & Coil

PE coated aluminum sheets and coils are available in a variety of colors, textures and thicknesses to meet different architectural and design requirements. The surface can be smooth or embossed, matte or glossy, and can be customized with patterns or images.

Advantages

- It has a high thermal conductivity, allowing it to dissipate heat and regulate temperature effectively.

- This makes it an ideal material for roofing and cladding systems, where it can minimize energy consumption and improve indoor comfort.

- PE coated aluminum is also easy to install and maintain.

- The material is lightweight, easy to cut and bend.

- And it has good shaped to fit any design.

- It is easy to clean with a soft cloth or water, and does not require any special treatment or painting.

Application

- At present, PE coated aluminum is widely used in building and construction industry, including commercial buildings, industrial buildings, airports, railways, hospitals, schools, and residential buildings.

- Its versatility, durability and affordability make it an ideal choice for architects, builders and contractors.

- In summary, PE coated aluminum is an excellent material that offers numerous advantages for building and construction industry.

- It is a top choice for architects and builders around the world, with its corrosion resistance, durability, aesthetic finish, thermal conductivity, ease of installation and maintenance, and sustainability.

Powder PE Coated Aluminium Sheet

Compared liquid coating, powder coating does not require any solvents or thinners. It is a more environmentally friendly option. The powder coating process involves electrostatically spraying the powder coating onto the surface of the aluminum sheet, which then fuses into a solid coating under high heat.

The powder PE coating provides a durable and protective layer on the surface of the aluminum sheet, providing excellent resistance to weathering, corrosion, and UV radiation. It also enhances the aesthetic appeal of the sheet, providing a smoother and more consistent finish, compared to liquid coatings.

Advantages

One of the key advantages of powder PE coated sheet is its long lifespan. Because of its superior resistance to weathering and corrosion, it can last for many years without requiring extensive maintenance or replacement. This makes it a cost-effective and sustainable material for building and construction projects.

In summary, powder PE coated aluminium sheet is a high-quality material that provides superior durability, protection, and aesthetic appeal for different applications within the building and construction industry. Its versatility, long lifespan, and environmentally friendly manufacturing process make it an attractive choice for architects, builders, and contractors alike.

What Is Powder PE Coated Sheet

Powder PE coated aluminum sheets are available in a wide range of colors, textures, and thicknesses, which makes them a versatile material for different applications within the building and construction industry.

Its versatility and durability make it an attractive option for applications such as roofing systems, cladding, facades, and composite panels.

What is PE Coated Aluminum?

PE coated aluminum is a sustainable material that can contribute to green building practices. It is fully recyclable, and indefinitely without losing its properties. The material is also low in VOC emissions. It reduces the environmental impact of building construction.

What Is PE?

PE stands for Polyethylene, a type of polymer that offers superior mechanical properties and toughness to aluminum. PE coating is achieved by applying a layer of thermoplastic material on the surface of the aluminum sheet through a process of extrusion or lamination. The coating creates a barrier against moisture, UV radiation, chemicals and other environmental factors.