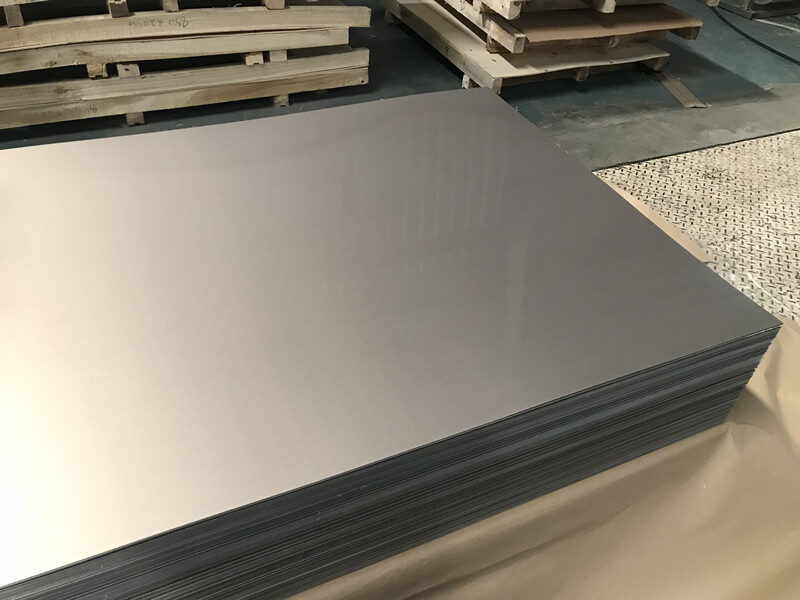

Mill Finish Aluminum

Mill finish aluminum means that the aluminum circle, sheet, coil or strip without any surface treatment. After simple processing, without any complex machining procedures such as roller coating. This type of aluminum product retains the original color of the aluminum material.

The classification

It’s easy to distinguish these relative products. We can distinguish aluminium products just by their appearance.

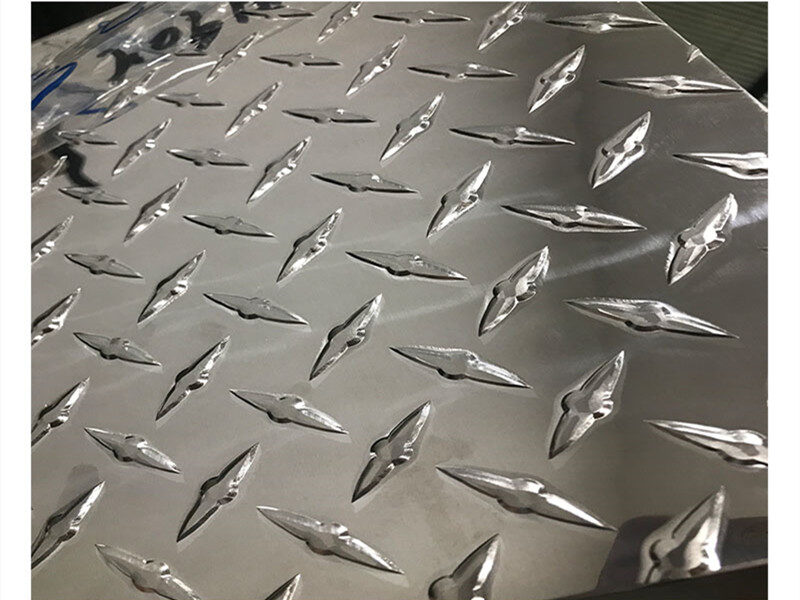

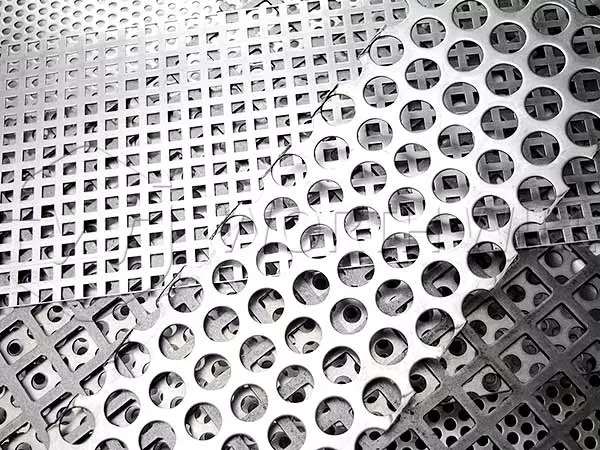

Same: All of these products have natural color like silver on the surface.

Different: They are different in shape and surface treatment. Aluminum circle has round shape and smooth surface. Aluminum checkered plate has the one bar or five bar pattern on the surface of the product. Embossed aluminum plate’s surface with some like orange, and others patterns.

If you want to know more the difference and clearly, you can go to WORTHWILL official website to view the pictures and ask our salesmen. They will answer you enthusiastically.

Specification

Below is a standard specification table for mill finish aluminum:

| Property | Description |

|---|---|

| Alloy | 1050, 1060, 1100, 3003, 5052 |

| Thickness | 0.2mm – 10mm |

| Width | 500mm – 2000mm |

| Length | Coil or Custom Cut Sheets |

| Temper | O, H12, H14, H16, H18, H24, H32 |

| Surface | Smooth metallic, uncoated finish |

Application

Mill finish aluminum is suitable for multiple applications across different industries:

Construction panels and facades

Roofing and insulation cladding

Electrical enclosures and panels

Machinery and equipment covers

Interior decoration and signage

Transport and automotive body parts

What are the advantages of mill finish aluminum?

Cost-effective

Lightweight and strong

Easy to machine and fabricate

Recyclable and eco-friendly

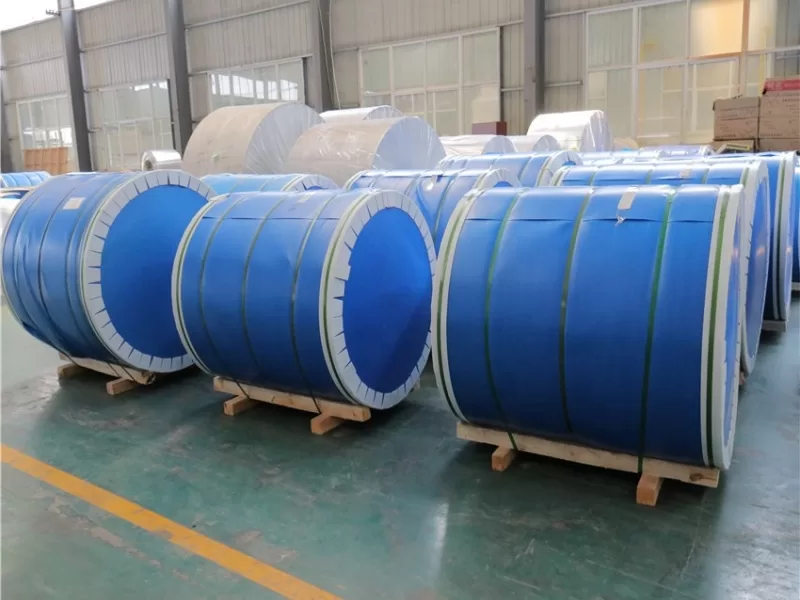

Packaging

To ensure safe delivery, mill finish aluminum is packed with:

Protective film or interleaving paper

Wrapped coils or flat sheets

Moisture-proof packaging

Wooden pallets or crates for export

Frequently Asked Questions

Q: Does mill finish aluminum rust?

A: No – It forms a self-protecting oxide layer that prevents rust (unlike steel).

Q: Can mill finish be polished?

A: Yes – Achieves mirror finish with progressive abrasives (80→3000 grit).

Q: How does it compare to brushed aluminum?

A:

| Characteristic | Mill Finish | Brushed Finish |

|---|---|---|

| Appearance | Uniform matte | Directional grain |

| Cost | $ | $$ |

| Maintenance | Low | Medium |

Q: Is chemical cleaning required before welding?

A: Recommended – Use alkaline cleaner to remove rolling oils.