Black anodized aluminum is a popular material that combines the lightweight, durable properties of aluminum with the sleek, modern appearance of a matte or glossy black finish. This versatile material is widely used in various industries, from architecture and automotive to electronics and consumer products. Its aesthetic appeal, combined with its resistance to corrosion, wear, and environmental factors, makes black anodized aluminum an excellent choice for both functional and decorative applications.

What is Black Anodized Aluminum?

Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum. This process improves aluminum’s durability and resistance to corrosion.

This makes black anodized aluminum highly resistant to chipping, peeling, and fading, even under harsh conditions.

Key Benefits

- Sleek Aesthetic Appeal One of the most prominent features of black anodized aluminium is its elegant and modern appearance. The matte or glossy black finish can give products a high-end look, making it an attractive option for architectural details, consumer electronics, and automotive trim.

- Corrosion Resistance Anodized aluminum is naturally resistant to corrosion due to its enhanced oxide layer, and the anodizing process further strengthens this protection.

- Durability and Wear Resistance The anodizing process creates a hard, scratch-resistant surface, making black anodized aluminum highly durable.

- Lightweight and Strong Such as aerospace, automotive, and electronics.

- UV and Fade Resistance The black dye used in the anodizing process is UV-stable, which means it won’t fade or discolor when exposed to sunlight.

- Environmentally Friendly Anodizing is an environmentally friendly process that doesn’t use harsh chemicals or produce hazardous byproducts. The anodized aluminum is also 100% recyclable, making it a sustainable option for projects focused on minimizing environmental impact. Additionally, anodized aluminum has a longer lifespan than many other materials, reducing the need for replacements and contributing to resource conservation.

Applications

Black anodized aluminum has uses in a wide range of industries, thanks to its combination of durability, lightweight design, and attractive finish. Some of the most common applications include:

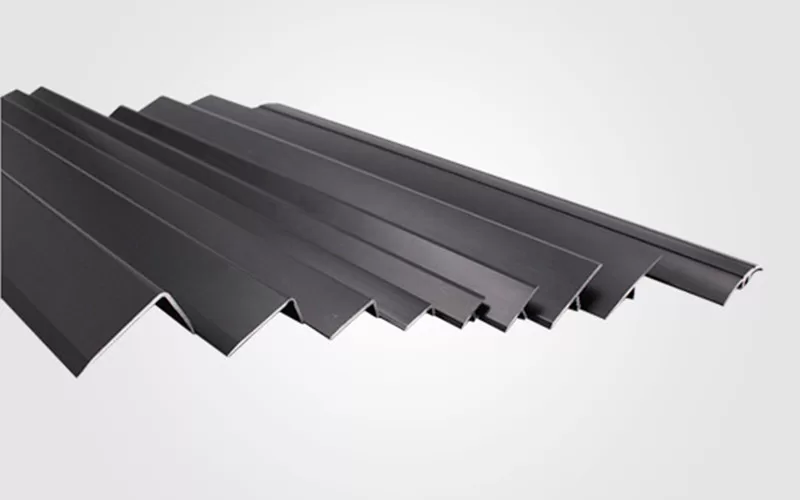

- Architecture and Construction In architecture, black anodized aluminum has uses for window frames, door frames, curtain walls, and other structural elements that require corrosion resistance and a modern aesthetic.

- Automotive and Aerospace The lightweight strength of aluminum makes it a popular choice in the automotive and aerospace industries.

- Consumer Electronics Many consumer electronics, such as smartphones, laptops, and audio equipment, feature black anodized aluminium casings.

- Furniture and Interior Design You’ll often find anodized aluminum in items like table legs, chair frames, shelving, and decorative panels.

- Signage and Displays The high contrast of black anodized aluminum makes it a great material for signage, displays, and plaques. Additionally, it can be easily machined or engraved. It is ideal for custom logos and text.

- Industrial and Mechanical Parts The non-reflective black finish is also beneficial in environments where glare needs.

Maintenance and Care

Black anodized aluminium requires minimal maintenance to keep it looking its best. For regular cleaning, you can use mild soap and water to wipe down the surface. Avoid using harsh chemicals or abrasive materials, as these can damage the anodized layer. With proper care, black aluminum can maintain its color and finish for many years.

Is Black Anodized Aluminum Right for Your Project?

If you’re looking for a material that combines style, strength, and durability, black aluminum is an excellent option. It offers a sleek, modern aesthetic while providing long-lasting protection against corrosion, wear, and UV exposure. Whether you’re working on architectural projects, consumer products, or industrial applications, anodized aluminum delivers both functional and aesthetic benefits.

Conclusion

Black anodized aluminum is the perfect choice for applications that require both durability and a premium appearance. Its combination of lightweight strength, resistance to corrosion and wear, and sleek black finish makes it ideal for industries ranging from architecture to consumer electronics. If you’re looking to add style and longevity to your next project, black anodized aluminium is the right material to consider.