Aluminum Jacketing For Pipe Insulation

Aluminum jacketing is a popular solution for protecting pipe insulation from physical damage and environmental elements.

It is a cost-effective and efficient method for insulating pipes and tubes that carry fluids at different temperatures.

The use of aluminum jacketing provides a protective barrier to the insulation.

It helps to maintain the thermal performance and energy efficiency of the insulation system.

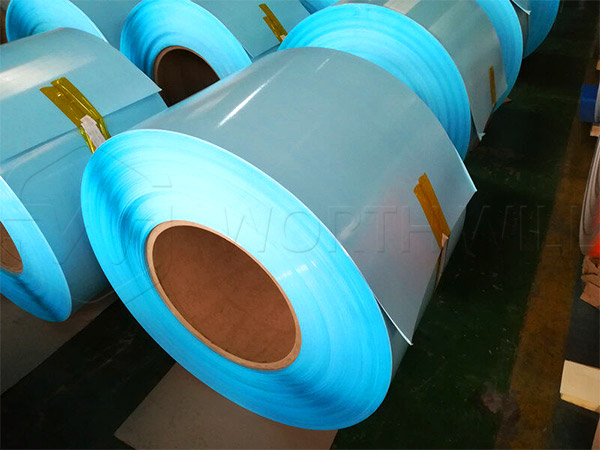

Worthwill Aluminum Jacketing Roll

Aluminum jacketing comes in a variety of shapes and sizes, including sheets, rolls, and banding.

The most common form is roll jacketing, which is made up of a thin layer of aluminum that is rolled onto a core material.

The core material can be made of different materials, such as fiberglass, mineral wool, or foam, depending on the application requirements. Aluminum sheet and banding are also used to cover insulation in specific areas, such as valves, elbows, and tees, where cutting and fitting are required.

Durability and corrosion resistance

Aluminum is a non-ferrous metal.

- This makes aluminum jacketing ideal for outdoor applications, where exposure to the elements.

UV radiation

harsh chemicals

They can cause damage to the insulation and reduce its effectiveness.

- The corrosion resistance of aluminum jacketing also helps to extend the service life of the insulation system, reducing the need for frequent maintenance and replacement.

Low thermal conductivity

- Aluminum is a poor conductor of heat, which means it does not conduct heat well. This property helps to reduce heat loss or gain, which can lead to energy savings and lower operating costs.

- The low thermal conductivity of aluminum jacketing also helps to prevent moisture infiltration and condensation.

- On the insulation surface, which can have negative effects on the insulation and the surrounding equipment.

Installation

Aluminum jacketing is easy to install, which helps to save time and labor costs.

We can customize the roll and sheet for the specific dimensions of the insulation system.

The installation of aluminum jacketing is typically with adhesive or mechanical fasteners. Depending on the application requirements and the strength of the insulation system.

Why To choose Aluminum Jacketing For Pipe Insulation?

In conclusion, aluminum jacketing is a practical and economical solution for protecting pipe insulation from physical damage and environmental factors.

durability

corrosion resistance

low thermal conductivity

ease of installation

So, it is an ideal choice for insulating pipes and tubes in various industries, including petrochemicals, oil and gas, HVAC, and refrigeration.