Introduction

Aluminum alloys are essential materials in today’s manufacturing world, valued for their lightweight nature, durability, and resistance to corrosion. Among the most widely used grades is 3003 aluminum, especially in the H14 temper. When you specify ASTM B209 Alloy 3003 H14, you are referring to a high-quality aluminum sheet that meets specific industry standards for composition and mechanical properties.

This guide aims to provide a clear understanding of what ASTM B209 Alloy 3003 H14 means. We will break down the alloy, the temper, the standard, and discuss its practical uses. If you are sourcing aluminum sheet or aluminum coil for your projects and need reliable information on 3003 H14, read on to learn about its specifications, benefits, and applications. We will cover everything from its chemical makeup to why it’s a preferred choice for many manufacturers.

What is ASTM B209 Alloy 3003 H14?

To fully grasp ASTM B209 Alloy 3003 H14, we need to look at each part: the standard (ASTM B209), the alloy (3003), and the temper (H14). Together, they define a specific type of aluminum sheet with consistent characteristics. This section directly addresses “What is 3003 H14 ASTM?”.

What is 3003 Aluminum?

3003 aluminum is a non-heat-treatable alloy belonging to the 3xxx series. Its primary alloying element is manganese, typically added in amounts around 1.0% to 1.5%. This manganese content significantly improves the strength of pure aluminum without negatively impacting its excellent workability or corrosion resistance.

What does H14 mean in Aluminum?

The “H” in H14 indicates that the aluminum has been strain-hardened. Strain hardening, or work hardening, is achieved by cold working the metal (such as rolling it at room temperature). This process increases the metal’s strength and hardness but reduces its ductility. The numbers following the “H” provide more detail about the specific strain-hardened temper:

- The first digit (“1”) means the material has been strain-hardened only.

- The second digit (“4”) indicates the degree of hardening. On a scale from 0 (annealed/soft) to 8 (full hard), “4” represents a half-hard condition.

This gives 3003 H14 a good balance of moderate strength and still-excellent formability, allowing it to be easily bent, shaped, and deep-drawn. This directly answers “What does H14 mean in aluminum?”.

What is ASTM B209 Material?

ASTM B209 is the standard specification from the American Society for Testing and Materials (ASTM) that covers aluminum and aluminum-alloy sheet and plate. This standard is crucial because it sets the requirements for the chemical composition, mechanical properties (like tensile strength, yield strength, and elongation), dimensional tolerances (thickness, width, length), and testing procedures for various aluminum alloys and tempers in sheet and plate form.

When an aluminum sheet product is specified as conforming to ASTM B209, it means the manufacturer has produced the material according to the strict guidelines outlined in this standard. This ensures consistency, quality, and reliability across different suppliers and batches. So, ASTM B209 material refers to aluminum sheet or plate that meets the requirements of this widely recognized standard. This directly answers “What is ASTM B209 material?”.

This guarantees you receive a product with predictable performance characteristics suitable for its intended applications.

Key Specifications of ASTM B209 Alloy 3003 H14

Understanding the precise specifications is vital when selecting ASTM B209 Alloy 3003 H14 aluminum sheet. Our products are manufactured to meet these rigorous standards, ensuring quality and suitability for diverse applications.

| Specification Category | Details |

|---|---|

| Product | ASTM B209 Alloy 3003 H14 Aluminum Sheet / Coil |

| Standards | ASTM B209, C1729 (Relevant standards for flat rolled aluminum products) |

| Alloy | 3003 (Other available alloys: 3105, 5005, 6061, 6082) |

| Temper | H14 (Other common tempers: H16, H24. Special tempers available upon request) |

| Thickness | 0.3mm to 1.5mm |

| Width | 914mm, 1000mm, 1219mm (Other widths available on orders) |

| Lengths | 100’ (approx. 30m), 200’ (approx. 60m), Jumbo Roll (Other lengths on order) |

| Surface Finish | Mill Finish (Standard as-rolled surface) |

These ASTM B209 3003 H14 aluminum sheet specifications ensure that the material provides the expected mechanical properties, dimensional accuracy, and quality required for manufacturing and construction. We can supply ASTM B209 compliant 3003 H14 aluminum sheet and 3003 aluminum coil in these common configurations and are flexible for custom requirements.

Chemical Composition of 3003 Aluminum

The specific properties of Alloy 3003 are a direct result of its chemical makeup. Meeting the ASTM B209 standard for 3003 aluminum means adhering to the defined limits for each alloying element. The typical chemical composition is:

| Element | Percentage (%) (ASTM Limits, Typical) |

|---|---|

| Silicon (Si) | 0.6 max |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.05 – 0.20 |

| Manganese (Mn) | 1.0 – 1.5 |

| Magnesium (Mg) | 0.05 max |

| Zinc (Zn) | 0.10 max |

| Other Each | 0.05 max |

| Other Total | 0.15 max |

| Aluminum (Al) | Remainder |

The controlled percentage of Manganese is key to the increased strength of 3003 aluminum compared to pure aluminum, while keeping other elements low helps maintain its excellent formability and corrosion resistance.

Comparing ASTM B209 3003 H14 with Other Aluminum Alloys

Choosing the right aluminum alloy and temper depends heavily on the application’s specific needs. Here, we compare ASTM B209 Alloy 3003 H14 with other commonly used grades to highlight their differences.

3003 H14 vs. 6061 T6

Comparing 3003 H14 with 6061 T6 involves looking at alloys from different series and tempers achieved through different processes.

- Alloy Type: 3003 (3xxx series, Al-Mn) is a non-heat-treatable alloy. 6061 (6xxx series, Al-Mg-Si) is a heat-treatable alloy.

- Temper Process: H14 is strain-hardened (cold worked). T6 is heat-treated (solution heat treated and artificially aged).

- Strength & Hardness: 6061 T6 is significantly stronger and harder than 3003 H14. 6061 T6 is used for structural applications requiring high strength.

- Formability: 3003 H14 offers excellent formability and is much easier to bend, deep draw, and shape than the much harder 6061 T6.

- Weldability: Both are generally weldable, but welding 6061 T6 can reduce strength in the weld zone unless post-weld heat treatment is performed.

- Corrosion Resistance: Both have good general corrosion resistance, but 3003 H14 is often preferred for applications like cookware due to its composition.

Choose ASTM B209 Alloy 3003 H14 for applications needing moderate strength, excellent formability, good corrosion resistance, and cost-effectiveness. Choose 6061 T6 for structural components where high strength is paramount.

3003 H14 vs. 5052 Aluminum

This comparison is between two non-heat-treatable alloys but from different series with different primary alloying elements.

- Alloy Type: 3003 (3xxx series, Al-Mn). 5052 (5xxx series, Al-Mg) with significantly more magnesium than 3003.

- Strength: 5052 is generally stronger than 3003 in comparable tempers (e.g., 5052-H34 is stronger than 3003-H14).

- Formability: 3003 H14 typically has slightly better deep drawing capabilities than 5052 in similar strength tempers, while 5052 still offers very good formability.

- Corrosion Resistance: 5052 offers superior corrosion resistance compared to 3003, especially in marine environments and against alkalis, due to its higher magnesium content.

- Cost: 3003 is usually less expensive than 5052.

Choose ASTM B209 Alloy 3003 H14 for general purposes where cost, moderate strength, and good formability are key. Choose 5052 when higher strength than 3003 is needed and excellent corrosion resistance is critical, particularly in harsh environments.

What is equivalent to 3003 H14 aluminum?

Direct, identical equivalents across all international standards can be difficult to name because different standards (like EN, JIS, etc.) have slightly different alloy compositions and temper designations. However, other standards do have alloys and tempers that are considered functionally similar to ASTM B209 Alloy 3003 H14 for many applications. For example, EN AW-3003 is the European equivalent alloy number, and a “half-hard” temper would be sought (like H14 or H24 depending on the exact process). When seeking an equivalent, it is best to consult the specific standards of the required material and compare the chemical composition and mechanical property requirements (like tensile and yield strength according to that standard) to those defined by ASTM B209 for Alloy 3003 H14. There isn’t a single universal “equivalent” that is perfectly identical in all aspects worldwide.

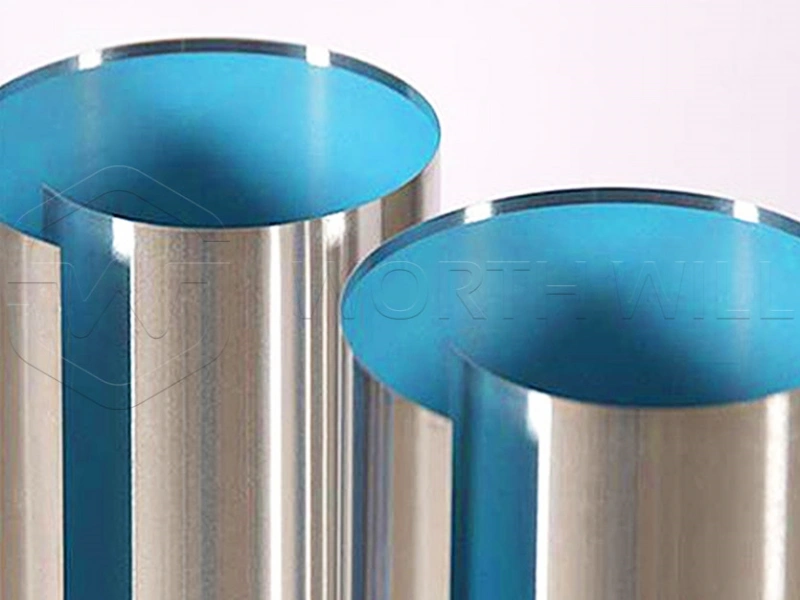

Types of 3003 H14 Aluminum Product

ASTM B209 Alloy 3003 H14 is primarily supplied in flat forms to meet manufacturing needs.

- Aluminum Sheet: This is the material cut to specified lengths from larger rolls or coils. It’s ready for processing in sheet-fed equipment. It’s a common form for general fabrication.

- Aluminum Coil: This is the continuous strip of ASTM B209 3003 H14 material wound into a large roll. 3003 aluminum coil is ideal for large-volume manufacturing processes like stamping, roll forming, or slitting, where a continuous feed is advantageous. Jumbo rolls are available for maximum efficiency.

Both aluminum sheet and aluminum coil formats adhere to the ASTM B209 standard for Alloy 3003 H14, ensuring consistent properties regardless of the form factor.

Package

Proper packaging is crucial for protecting ASTM B209 Alloy 3003 H14 aluminum sheet and coil during transit and storage. Standard packaging typically includes:

- Interleaving paper or protective film between sheets to prevent scratching of the surface finish.

- Secure strapping around bundles of sheets or coils.

- Robust wooden pallets or crates for easy handling and stable stacking.

- Waterproof wrapping or other protective barriers, especially for seaworthy export packaging, to prevent moisture damage.

We take care to ensure your ASTM B209 3003 H14 aluminum arrives in excellent condition, ready for your production process. Custom packaging solutions can be arranged upon request.

Common Applications of ASTM B209 Alloy 3003 H14

Thanks to its balanced properties – moderate strength, excellent formability, good corrosion resistance, and cost-effectiveness. ASTM B209 Alloy 3003 H14 aluminum sheet is used in a vast range of applications across various industries.

- Kitchenware and Cookware (pots, pans, bakeware)

- Storage Tanks and Vessels (chemical tanks, fuel tanks)

- HVAC Systems (heat exchangers, ductwork)

- Building Products (roofing, siding, trim, flashing)

- Trailer and Truck Bodies

- Signs and Nameplates

- Electronic Chassis and Cabinets

- Piping and Tubing (low pressure)

- Fin Stock for Coolers

- General Fabrication requiring bending and drawing

The reliability provided by conforming to the ASTM B209 standard, combined with the inherent benefits of Alloy 3003 and H14 temper, makes this material a dependable choice for these diverse uses.

Why Choose Us for ASTM B209 Alloy 3003 H14?

Selecting a trusted supplier for your ASTM B209 Alloy 3003 H14 aluminum sheet and coil needs is essential for project success. We pride ourselves on providing high-quality products and excellent service.

Information

- Guaranteed Quality: We strictly adhere to ASTM B209 and other relevant standards like C1729, ensuring every batch of 3003 H14 aluminum meets the required chemical composition, mechanical properties, and dimensional tolerances.

- Extensive Selection: We maintain a large inventory of 3003 H14 aluminum sheet and coil in various standard thicknesses and widths. We also offer other alloys like 3105, 5005, 6061, and 6082, and different tempers (H16, H24, etc.).

- Custom Capabilities: Need non-standard widths, lengths, or even special tempers? We offer customization options to supply the exact ASTM B209 compliant 3003 H14 aluminum you require.

- Competitive Pricing: We offer competitive rates on our 3003 H14 aluminum sheet, providing cost-effective solutions without sacrificing quality.

- Reliable Delivery: Our efficient logistics team ensures prompt and secure delivery of your aluminum sheet or coil, whether it’s a standard order or a large jumbo roll.

- Expert Knowledge: Our team possesses deep expertise in aluminum alloys and their applications. We can assist you in selecting the best material and specifications for your specific project needs.

Partner with us to ensure you receive high-quality ASTM B209 Alloy 3003 H14 aluminum sheet that is reliable, meets standards, and is delivered on time.

Conclusion

ASTM B209 Alloy 3003 H14 aluminum sheet is a foundational material in many industries, prized for its excellent balance of properties including moderate strength, high formability, good corrosion resistance, and cost-effectiveness, all guaranteed by the rigorous ASTM B209 standard.

Understanding the specifics of Alloy 3003, the H14 temper, and the ASTM B209 standard is crucial for selecting the right material for your needs. Whether you require 3003 H14 aluminum sheet for manufacturing cookware, building components, or industrial equipment, its consistent quality makes it a dependable choice.

If you are looking for a reliable supplier of ASTM B209 Alloy 3003 H14 aluminum sheet or aluminum coil, or have questions about our products, please contact us today. We are ready to help you find the perfect aluminum solution for your project.