Aluminum foil is made from 98.5-99.9% pure aluminum, blended with trace elements to enhance specific properties. The exact composition varies by foil type and intended use.

✔ Primary Material: Refined aluminum (bauxite ore derivative)

✔ Alloy Additives: Iron, silicon, manganese (≤1.5% combined)

✔ Purity Standards:

- Food-grade: ≥99% pure

- Industrial: 98.5-99.2% pure

Raw Materials & Production Process

1. Bauxite Mining

- Aluminum originates as bauxite ore (40-60% alumina content)

- Top producers: Australia, China, Guinea

2. Alumina Refining (Bayer Process)

- Bauxite → Aluminum oxide (Al₂O₃)

- 4-5 tons bauxite = 2 tons alumina

3. Smelting (Hall-Héroult Process)

- Alumina + Cryolite → Molten aluminum (99.5% pure)

- Energy-intensive: 13-15 kWh per kg produced

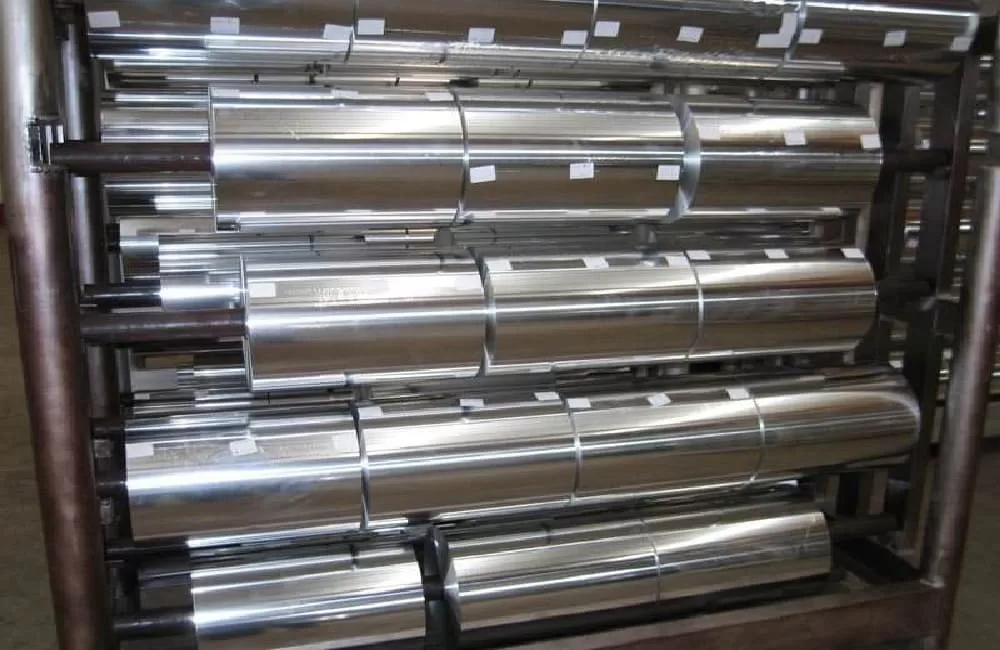

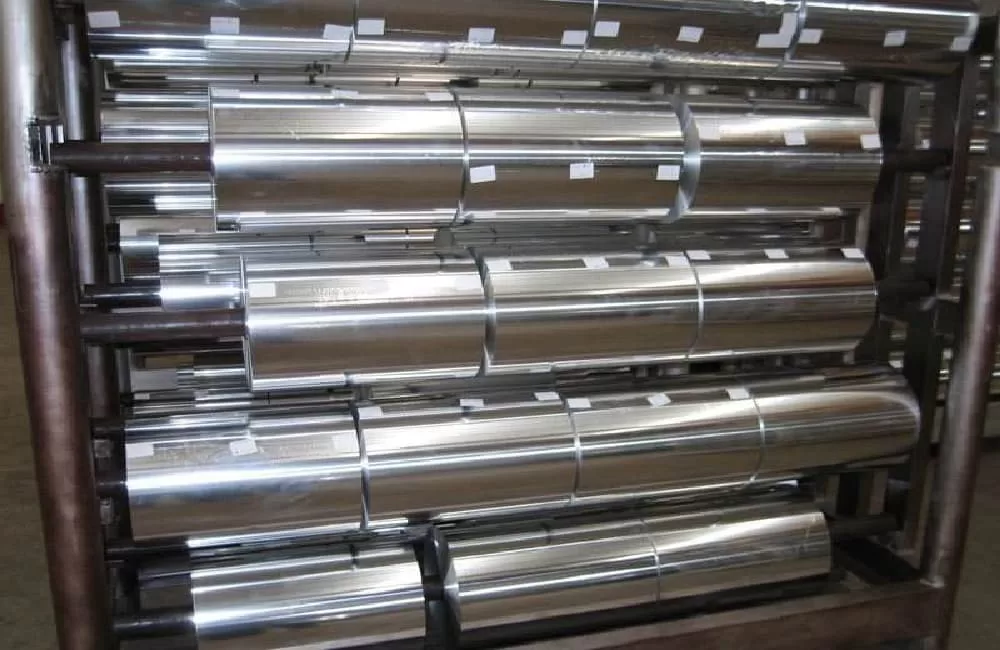

4. Foil Manufacturing

| Step | Key Details |

|---|---|

| Casting | Molten aluminum → 20-60cm thick slabs |

| Hot Rolling | Slabs heated & rolled to 2-6mm thickness |

| Cold Rolling | Final thinning to 0.006-0.2mm |

| Annealing | Heat treatment for flexibility (O-temper) |

Types of Aluminum Foil Alloys

| Alloy | Composition | Best For |

|---|---|---|

| 1050 | 99.5% Al | Food packaging, capacitors |

| 1145 | 99.45% Al | Pharmaceutical blister packs |

| 8011 | Al-Fe-Si | Container lids, household foil |

| 3003 | Al-Mn | Insulation, industrial uses |

Key Difference:

- 1xxx series: High purity, best for food

- 3xxx/8xxx: Added strength for technical applications

Why These Materials Matter

Food Safety

- FDA-approved alloys (1050, 1145) resist metal transfer

- Naturally forms oxide layer to prevent corrosion

Performance Factors

- Thinner foil (0.006mm): More flexible but tears easily

- Thicker foil (0.2mm): Better heat conduction

Sustainability

- Recyclability: Aluminum foil can be reused indefinitely

- Energy savings: Recycling uses 95% less energy than primary production

Foil vs. Other Materials

| Property | Aluminum Foil | Plastic Wrap | Parchment Paper |

|---|---|---|---|

| Heat Resistance | 660°C melting point | 160°C max | 220°C max |

| Recyclable | Yes | Rarely | No |

| Barrier Properties | Blocks light/oxygen | Permeable | Porous |

Common Misconceptions

Myth: Aluminum foil contains harmful chemicals

Fact: Food-grade foil meets strict FDA/EFSA standards

Myth: Shiny vs. dull sides have different properties

Fact: Both sides function identically (difference comes from manufacturing)

FAQ

Q: Is aluminum foil pure aluminum?

A: Nearly pure (98.5-99.9%), with tiny alloy additions for strength.

Q: Why does some foil tear easily?

A: Thinner gauges (<0.016mm) sacrifice durability for flexibility.

Q: Can you recycle used foil?

A: Yes, if clean – food residues may require separate processing.

Q: What’s the difference between household and industrial foil?

A: Household foil is thinner (0.016-0.024mm) and purer (>99%).

Industry Applications

Food Packaging

- Chocolate wrappers

- Yogurt lids

- Takeout containers

Technical Uses

- Battery electrodes

- HVAC insulation

- Cable shielding

Consumer Products

- Art supplies

- Beauty product packaging

- DIY crafts

Conclusion

Aluminum foil’s unique material composition makes it indispensable for food, industrial, and household uses. Its purity, recyclability, and versatility ensure ongoing demand across industries.

Need foil specifications? Contact us for technical datasheets!