Why Choose Aluminum Sheet Metal?

Aluminum sheet metal offers unmatched versatility for industrial, construction, and consumer applications. Its unique properties make it superior to many other metals in various use cases.

✔ Lightweight (1/3 the weight of steel)

✔ Naturally corrosion-resistant

✔ Highly formable and machinable

✔ 100% recyclable without quality loss

✔ Excellent thermal/electrical conductivity

Specifications of Aluminum Sheet Metal

| Parameter | Details |

|---|---|

| Thickness | 0.2mm (foil) to 6mm (plate) |

| Width | Up to 2,500mm (custom sizes available) |

| Alloys | 1050, 3003, 5052, 6061 (varies by application) |

| Temper | O (annealed), H12-H19 (work hardened) |

| Surface Finish | Mill, brushed, anodized, painted, embossed |

Key Advantages of Aluminum Metal

1. Superior Corrosion Resistance

- Forms protective oxide layer

- Ideal for marine/coastal applications

- No rust like steel

2. Exceptional Strength-to-Weight Ratio

- Strong yet lightweight

- Reduces structural load in buildings/vehicles

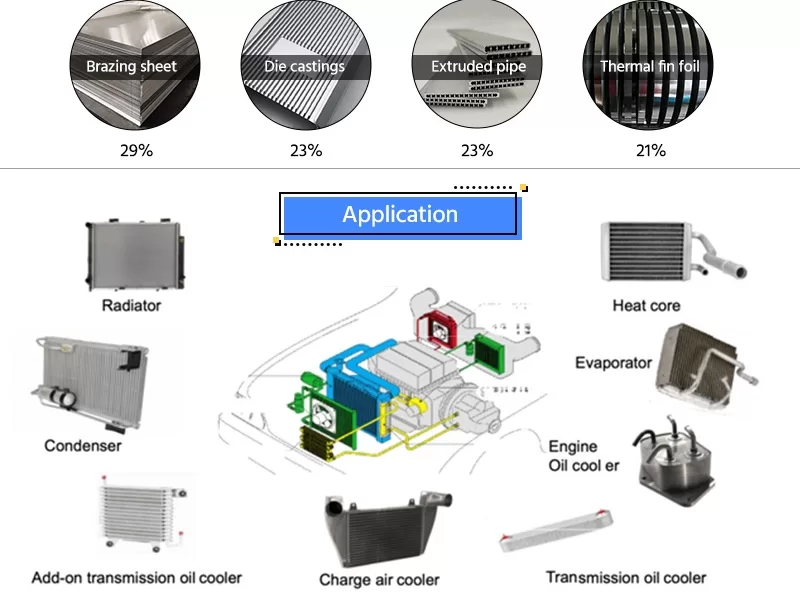

3. Thermal Conductivity

- 50x better than stainless steel

- Perfect for heat exchangers, cookware

4. Electrical Conductivity

- 60% of copper’s conductivity

- Used in busbars, electrical enclosures

5. Formability

- Easily bent, stamped, deep drawn

- Maintains strength after forming

6. Recyclability

- Uses only 5% energy vs. primary production

- No quality degradation when recycled

7. Non-Toxic & Hygienic

- Safe for food/medical applications

- FDA-approved for food contact

8. Aesthetic Flexibility

- Can be anodized in various colors

- Accepts powder coating well

9. Non-Magnetic

- Essential for electronics/medical equipment

10. Cost-Effective Long-Term

- Lower maintenance than steel

- Longer lifespan offsets initial cost

What Is Aluminum Sheet Metal Used For?

Construction Applications

- Roofing & siding (corrugated sheets)

- Window/door frames

- Curtain walls & composite panels

Transportation Industry

- Aircraft skins & components

- Automotive body panels

- Truck trailers & railcars

Industrial Uses

- Heat sinks & electronic enclosures

- Chemical tanks & piping

- Conveyor systems

Consumer Products

- Cookware & kitchen equipment

- Signage & decorative elements

- DIY projects & crafts

10 Advantages of Aluminum Roofing Sheets

- Lightweight – Easy to install, reduces structural load

- Corrosion Resistant – Lasts 50+ years in most climates

- Fireproof – Won’t combust (Class A fire rating)

- Energy Efficient – Reflects heat, lowers cooling costs

- Low Maintenance – No painting or rust treatment

- Design Flexibility – Available in various profiles/colors

- Weather Resistant – Withstands hail, high winds

- Recyclable – Sustainable building material

- Cost Effective – Long-term value outweighs initial cost

- Quick Installation – Large panels cover more area faster

Aluminum vs Steel Sheet Metal Comparison

| Property | Aluminum | Steel | Winner |

|---|---|---|---|

| Weight | 2.7 g/cm³ | 7.8 g/cm³ | Aluminum |

| Corrosion | Naturally resistant | Rusts easily | Aluminum |

| Strength | Moderate | Higher | Steel |

| Formability | Excellent | Good | Aluminum |

| Cost | Higher initial | Lower initial | Steel |

| Lifespan | 50+ years | 15-25 years | Aluminum |

| Maintenance | Minimal | Requires coating | Aluminum |

Best Choice When:

- Weight savings matter (aerospace, transportation)

- Corrosion resistance is critical (marine, chemical)

- Long-term cost matters more than upfront cost

Frequently Asked Questions

Q: Can aluminum sheets be welded?

A: Yes, using TIG or MIG methods. Alloys 5052 and 6061 weld best.

Q: How thick should aluminum sheet be for roofing?

A: 0.7mm-1.2mm for residential, 1.5mm+ for commercial.

Q: Does aluminum sheet metal rust?

A: No, it forms a protective oxide layer instead of rusting.

Q: What’s the best alloy for outdoor use?

A: 5052 or 3003 with painted/anodized finish.

Q: Can aluminum be used for food contact?

A: Yes, alloys 1050, 3003, and 5052 are FDA-approved.

Choosing the Right Aluminum Sheet

For Structural Applications

- 6061-T6 (high strength)

- 5083 (marine grade)

For Forming/Pressing

- 3003-O (excellent formability)

- 5052-H32 (good balance)

For Electrical Uses

- 1350 (high conductivity)

For Decorative Purposes

- Anodized 5005/6063

- Brushed finish

Is Aluminum Sheet Metal Better Than Steel Sheet Metal?

When comparing aluminum sheet metal to steel, the advantages of aluminum include:

Cost: While aluminum can be more expensive upfront, its long-term benefits often outweigh the cost.

Weight: Aluminum is about one-third the weight of steel, making it easier to handle.

Corrosion Resistance: Aluminum naturally resists rust, whereas steel needs additional coatings.

Workability: Aluminum is softer and easier to cut, bend, and weld than steel.

Durability: Aluminum lasts longer in outdoor and marine environments.