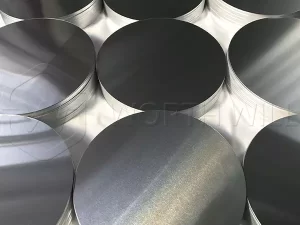

Aluminum Circle Plate

Aluminum circle plate is a type of high-quality aluminum product with wide use in various industries. These circular-shaped plates offer numerous benefits. Including excellent formability, durability, and corrosion resistance.

With their versatility and reliability, aluminum circles have become an indispensable material for applications ranging from cookware and lighting fixtures to automotive and aerospace components.

| Name | aluminum circles, aluminum circle blanks, aluminium disc, aluminum disk, aluminum wafer, round aluminum sheet plate, etc. |

| Aluminum Alloy | 1050, 1060, 1070, 1100, 3003, etc. |

| Temper | O, H12/H22, H14/H24, etc. |

| Thickness | 0.3mm – 6mm |

| Diameter | 100mm – 1500mm ( 3.94″ – 38.5″ ) |

| Surface treatment | anodized, polishing, colored coating, brushed, etc. |

Applications

The versatility of aluminum circle plates lends itself to a wide array of applications across multiple industries.

Some notable applications include:

Cookware: Widely used in the production of cookware, such as frying pans, saucepans, and baking trays. Their excellent heat conductivity ensures even heat distribution, resulting in efficient cooking and reduced energy consumption.

Lighting Fixtures: Serve as a fundamental component in the manufacturing of lighting fixtures, including lampshades and reflectors.

Automotive Industry: Finding extensive usage in the automotive industry, where they are utilized for manufacturing wheel rims, fuel tanks, and body panels.

Aerospace Industry: Widely employed in the aerospace sector for the fabrication of components such as aircraft fuselage panels, wing structures, and engine parts. Their high strength-to-weight ratio and corrosion resistance make them well-suited for aerospace.

Characteristics

As primarily manufacturing from high-grade aluminum alloys, it has 1xxx series and 3xxx series. These alloys possess exceptional mechanical properties. Thyey has ideal forming and fabrication processes.

Key characteristics of aluminum circles include:

Formability: With exhibiting excellent formability, easily shaped into various circular profiles without cracking or tearing. So, it makes them suitable for a wide range of applications.

Durability: For possessing high strength-to-weight ratio, it provides exceptional durability and structural integrity.

They can withstand harsh environments, temperature variations, and mechanical stress. They have suitable for long-lasting applications.

Corrosion Resistance: In inherent corrosion resistance. The formation of a natural oxide layer on the surface of aluminum provides a protective barrier against moisture, chemicals, and atmospheric elements. It ensures longevity and reducing maintenance costs.

Advantages

The use of aluminum circle offers several advantages over other materials. It is a preferred choice in various industries.

Some key advantages include:

Lightweight: It is easy to handle, transport, and install. This property is particularly beneficial for applications where weight reduction is crucial.

Such as automotive and aerospace industries, as it contributes to improved fuel efficiency and overall performance.

Heat Conductivity: This property is highly desirable in applications such as heat sinks, cooking utensils, and electrical components, where efficient heat transfer is essential for optimal performance and safety.

Recyclability: Environmentally friendly due to their high recyclability. It is a sustainable choice and reducing the need for primary aluminum production.

What Is Aluminum Circle?

Aluminum circle offers a versatile and reliable solution for a wide range of industrial applications. Their unique characteristics, including excellent formability, durability, and corrosion.