Aluminum Jacketing

Aluminum jacketing is typically using alloys 3105 or 3003 which have very similar composition and performance and are considered interchangeable for use as insulation jacketing.

Commercially pure aluminum is relatively soft and less suited for use in this application. Its strength can be greatly improved by alloying with small percentages of one or more other elements such as manganese, silicon, copper, zinc, and magnesium. Additional strength can be achieved by cold working.

Parameter:

Insulation material | Polysurlyn moisture barrier |

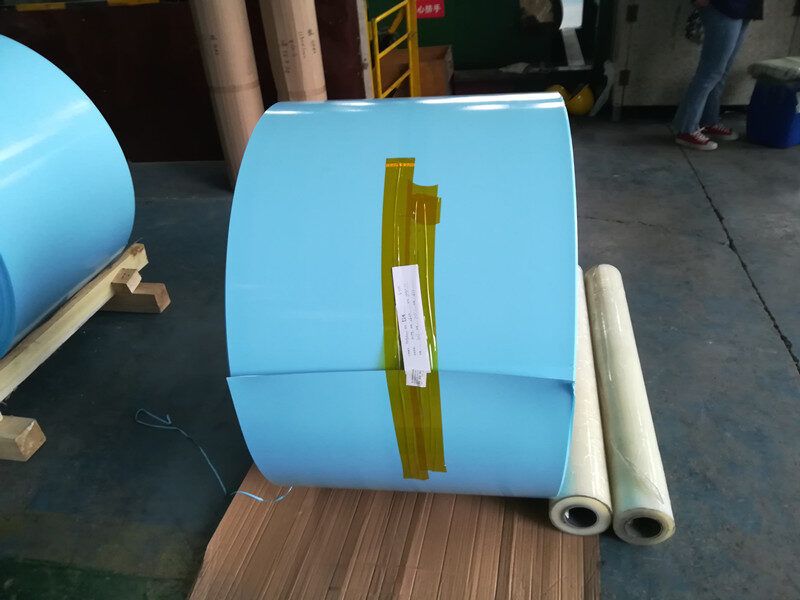

Surface | Stucco embossed /smooth/Corrugated |

Alloy | 1050, 1060,3105, 3003, etc |

Temper | H24 H16, etc |

Width | 200-1220mm(914mm/1000mm/1219mm) |

Length | Baby roll: 30M/60M/90M or as per request Jumbo roll |

Thickness | 0.4-1.5 |

Barrier color | Blue/Pink/Black or as per request |

Protection | POLYSURLYN FILM MOISTURE BARRIER |

MOQ | 3-5 tons |

PSMB

Polysurlyn film Moisture Barrier (PSMB) is an engineered three layer coextruded film of polyethylene and Surlyn* polymers with a total film thickness of 3 mils (76 µm) that is heat laminated in the factory to the interior surface of aluminum jacketing.

Use PSMB on all aluminum jacketing to help prevent pitting, crevice, and galvanic corrosion of the interior surface of the metal jacketing and the insulated pipe, tank, or equipment.Due to its superior performance characteristics, PFMB replaces the old moisture barrier technology of 1 to 3 mil thick polykraft paper.

PKMB

The thickness of moisture-proof kraft paper is 0.1-0.15mm. It has high strength bonding. The imported kraft paper is used for kraft paper. The kraft paper has the advantages of good ductility and strong moisture-proof function.

The moisture barrier is factory applied by attaching the jacketing by continuous lamination to the full width of the metal. The moisture barrier is used to prevent moisture and corrosives in the insulation from coming into direct contact with the metal jacketing surface and causing galvanic or chemical corrosion.