Created:

Jan 21, 2022Author:

WorthwillKeyword

Aluminum AlloyWhat Is Aluminum Alloy

Aluminum alloy is an alloy based on aluminum with a certain amount of other alloying elements added, and it is one of the light metal materials. In addition to the general characteristics of aluminum, aluminum alloys also have some specific characteristics of alloys due to the different types and quantities of alloying elements added. The density of aluminum alloy is 2.63~2.85g/cm3, with high strength (σb is 110~650MPa), the specific strength is close to that of high alloy steel, the specific stiffness exceeds that of steel, and it has good casting properties and plastic work-ability, and good electrical conductivity. , thermal conductivity, good corrosion resistance and weld-ability, can be used as a structural material, and has a wide range of applications in aerospace, aviation, transportation, construction, electronically, light and daily necessities.

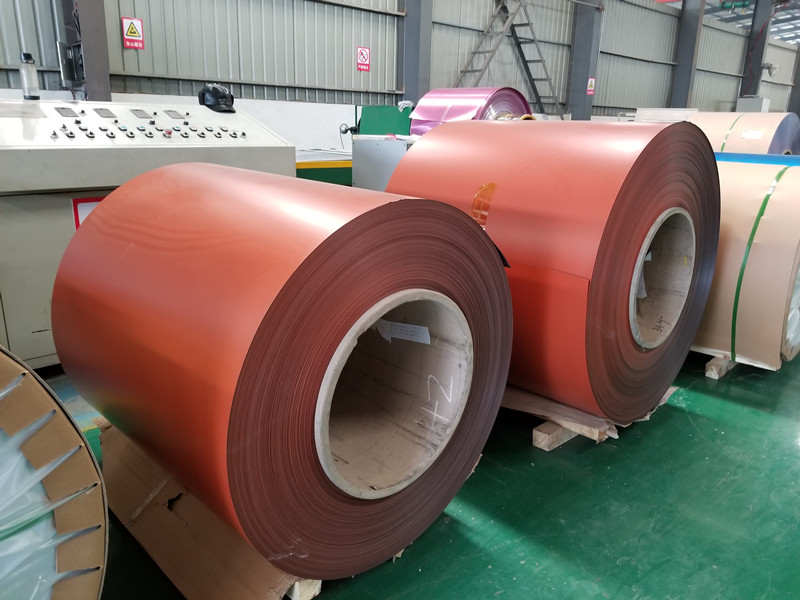

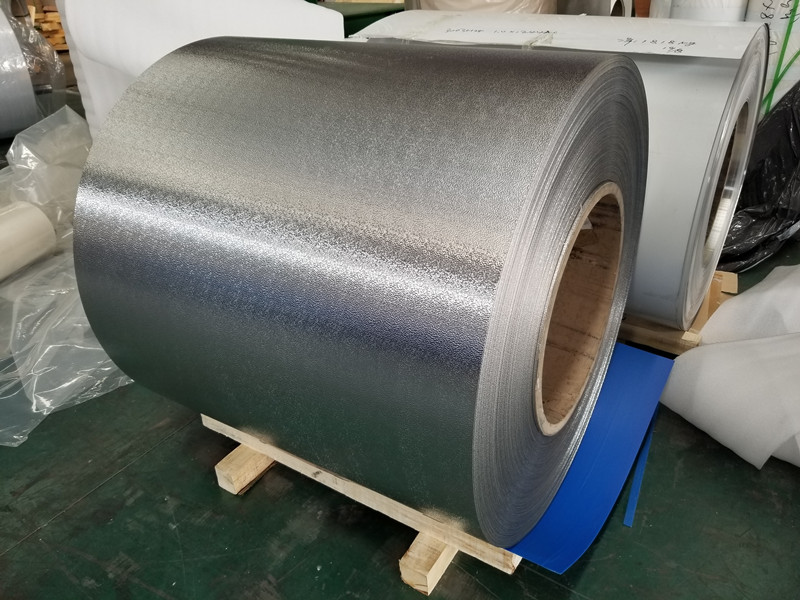

Aluminum alloys are divided into deformed aluminum alloys and cast aluminum alloys according to their composition and processing methods. Deformed aluminum alloys are made by first melting and casting alloy ingredients into billets, and then plastic deformation processing, and various plastic processing products are made by rolling, extrusion, stretching, forging and other methods. Cast aluminum alloy is a blank that is directly cast into various parts by sand mold, iron mold, investment mold and die casting method after smelting the ingredients. Deformed aluminum alloys are semi-finished aluminum alloys such as tubes, rods, wires, and shapes made by various pressure processing methods. According to its use, it can be divided into five categories: anti-corrosion aluminum alloy, super hard aluminum, special aluminum, hard aluminum, and forged aluminum.

Aluminum Alloy Application

The main alloying elements in the commonly used anti-rust aluminum alloys are manganese and magnesium. Adding manganese can improve its corrosion resistance, adding magnesium to strengthen it and reduce its specific gravity. It is characterized by corrosion resistance, good polish-ability, and can maintain a bright surface for a long time. The strength is higher than that of pure aluminum, and it is mostly used in the manufacture of parts, pipes, daily necessities, decorations, etc. that are in contact with liquids. Duralumin, also known as duralumin, is an alloy of aluminum, copper, and magnesium, and contains a small amount of manganese. Copper and magnesium are more soluble in aluminum and have a strengthening effect, and manganese makes them resistant to corrosion.

Hard aluminum can be used to manufacture rivets, aircraft propellers and high-strength parts on aircraft according to the content of its alloying elements; super hard aluminum is a hard aluminum containing zinc, and its hardness and strength are higher than that of hard aluminum. Different varieties of super hard aluminum It is used to manufacture various structural parts and high-load parts, and is one of the important materials in the aviation industry; forged aluminum has high plasticity and high strength under normal conditions, and is used to manufacture various forgings or stamping parts, such as internal combustion engine pistons; Special aluminum is used in specific situations, with different components, and each has its own purpose.