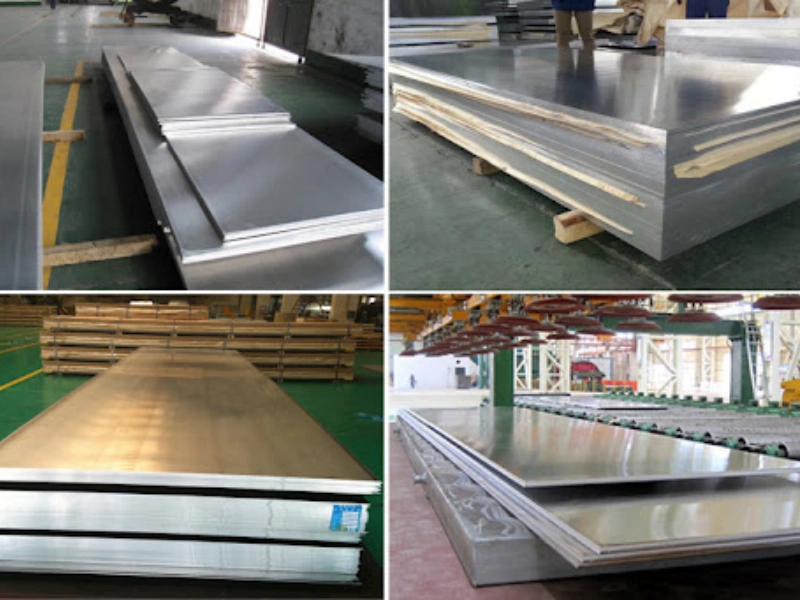

5052 Aluminum Plate

Specifications

| Property | Description |

|---|---|

| Commodity | 1050, 1060, 1100, 3003, 3004, 3105, 5005, 5052, 5083, 6061 |

| Temper | O, H14, H16, H18, H24, H26, H116, H321, T6, T651 |

| Thickness | 0.2mm – 100mm |

| Width | 10mm – 2700mm |

| Surface | Mill finish, brushed, anodized, coated |

| Standard | ASTM B209, JIS, GB, EN |

Popular Products

-

5052 H32 Aluminum Sheet

-

1/4″ 5052-H32 Aluminum Plate

-

1/8″ Aluminum Sheet 5052-H32

-

5052 Aluminum Sheet – O temper & H34 Sheet

-

5052 Aluminum Sheet H32 Mill Finish

-

Aluminum Plate – Series 5052-H32

-

Aluminum Plate 1/4″ (Grade 5052)

-

190 Aluminum Sheet 5052-H32 ASTM B209

Aluminum plate is a flat sheet of aluminum that is thicker than aluminum foil, but thinner than a sheet of aluminum. It is typically used in a variety of industrial, construction, and manufacturing applications.

Some common types of aluminum plate include:

- 1000 series aluminum plate: This is the purest form of aluminum plate, with a minimum 99% aluminum content. Used for chemical equipment and other applications that require high corrosion resistance.

- 2000 series aluminum plate: This series of aluminum plate contains copper. This gives it improved strength and stiffness, application in aerospace and defense applications.

- 3000 series aluminum plate: This series of aluminum plate contains manganese, which increases its strength and corrosion resistance. Commonly used in construction and transportation applications.

- 5000 series aluminum plate: This series of aluminum plate contains magnesium, which gives it high strength-to-weight ratio and excellent corrosion resistance. It is often used in marine and aerospace applications.

- 6000 series aluminum plate: This series of aluminum plate contains magnesium and silicon.gives it a high strength-to-weight ratio and excellent corrosion resistance., used in construction and transportation applications.

The choice of aluminum plate grade depends on the intended application, with factors such as strength, weight, heat resistance, and corrosion resistance being important considerations. It’s also a good thermal and electrical conductor.

Popular Thickness Options

Thin Gauge (0.2-3mm)

-

Applications: Signage, decorative panels, light fabrication

Medium Gauge (3-6mm)

-

Applications: Marine structures, vehicle panels

Heavy Plate (6-100mm)

-

Applications: Shipbuilding, offshore platforms

Top Applications of 5052 Aluminum Plate

Marine Industry

-

Boat hulls & decks

-

Dock components

-

Offshore platform structures

Transportation

-

Truck & trailer bodies

-

Railway cars

-

Aircraft components

Industrial Equipment

-

Chemical tanks

-

Pressure vessels

-

Heat exchangers

Architectural Uses

-

Marine-grade facades

-

Decorative panels

-

Ceiling systems

Common Tempers & Their Uses

5052-O (Annealed)

-

Softest form, excellent for deep drawing

-

Used in fuel tanks, chemical containers

5052-H32 (Strain Hardened)

-

Most popular temper

-

Used in marine components, truck bodies

5052-H34 (Strain Hardened)

-

Higher strength than H32

-

Used in aircraft parts, pressure vessels

5052 vs Other Aluminum Alloys

| Property | 5052 | 3003 | 6061 |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Good |

| Strength | Moderate | Low | High |

| Formability | Excellent | Excellent | Fair |

| Weldability | Excellent | Good | Good |

| Typical Uses | Marine, transport | General fabrication | Structural |

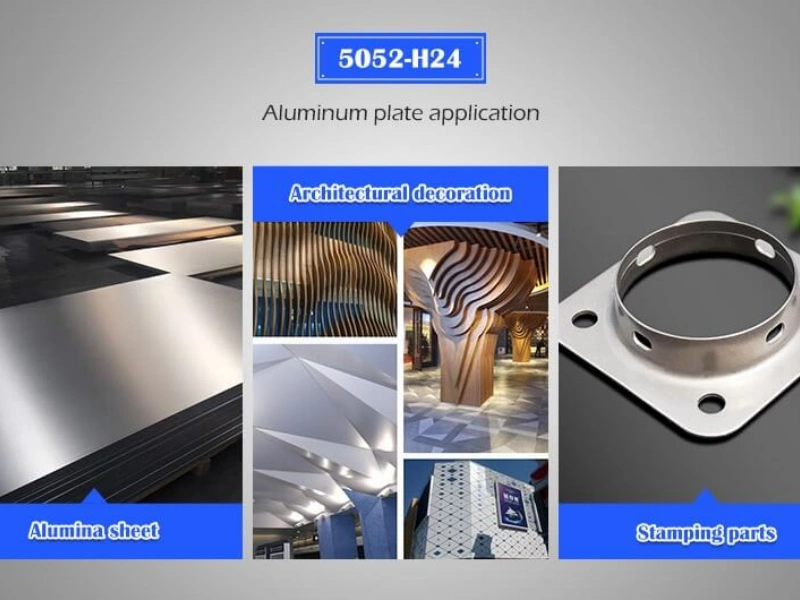

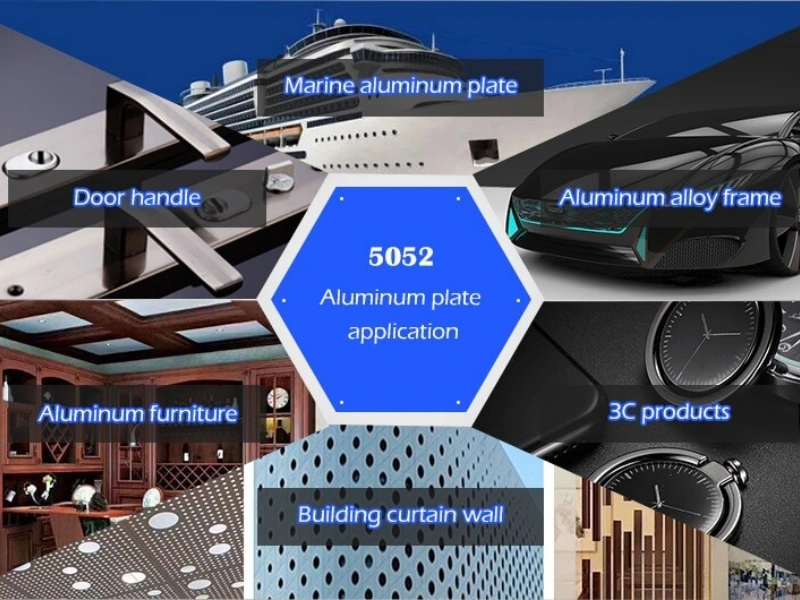

5052 Aluminum Plate Application

5052 aluminum plate is a popular choice for use in a wide variety of applications due to its high strength, excellent corrosion resistance, and good formability. Some common applications for 5052 aluminum plate include:

- Aerospace components

- Marine equipment and structures

- Transportation industry components, such as tankers and trucks

- Traffic signs

- Pressure vessels and tanks

- Sheet metal work and other architectural applications

- Automotive and electronic components

- Street light

- Kitchen equipment

- Railing and furnace

It has wide application in the manufacturing of electrical equipment, appliances, and in the construction industry for items such as storage tanks and roofing materials.

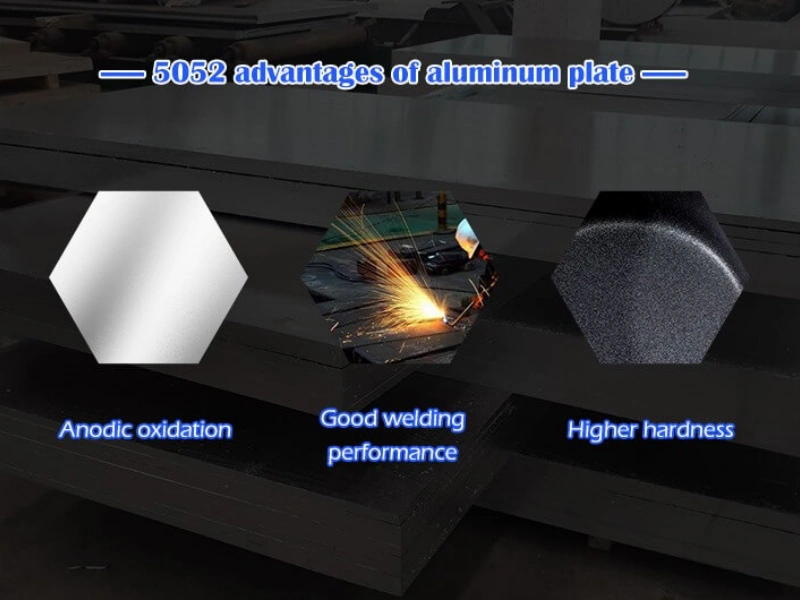

5052 aluminum plate is also non-heat treatable alloy and it’s one of the higher strength, non-heat-treatable alloys. It has good workability, medium static strength, high fatigue strength, good weldability, and very good corrosion resistance, especially in marine atmospheres.

What is 5052 Aluminum?

5052 aluminum is part of the 5000 series of aluminum alloys. These alloys are known for their good strength and excellent resistance to corrosion, especially in marine environments (like around saltwater). The main metal added to aluminum in the 5052 type is magnesium. This magnesium is what gives 5052 aluminum its special properties, particularly its strength and ability to fight off rust and wear.

Compared to other common aluminum types like 1000 series (pure aluminum) or 3000 series (like 3003 aluminum), 5052 aluminum offers a better balance. It’s stronger than the 1000 series and has much better corrosion resistance than the 3000 series. This makes the 5052 grade aluminum a very versatile option.

5052 Aluminum Plate Suppliers

Worthwill Aluminum is one of the trusted 5052 aluminum plate suppliers in China. With advanced production lines and years of experience, we offer stable supply and competitive prices for international customers.

Contact Us

Need 5052 aluminum sheet and plate for your project? Get in touch now:

-

WeChat/WhatsApp: +8615736973771

-

Email: jane@wwaluminum.com

Let’s discuss your needs and offer you the best aluminum solution.

5052 Aluminum Plate: A Great Choice for Many Jobs

Are you looking for a strong and durable metal that doesn’t rust easily? 5052 Aluminum Plate might be exactly what you need. This popular type of aluminum is used in many different products and industries because it has some really good qualities. It’s known for being tough, resisting corrosion, and being easy to work with. In this article, we will tell you all about 5052 aluminum plate, its uses, and why it’s a top material choice for many projects.

Why Choose Our 5052 Aluminum Sheet and Plate

-

Wide range of sizes and thicknesses

-

Strict quality control and compliance with standards

-

Fast production and delivery

-

Custom orders available

-

Excellent after-sales support

Frequently Asked Questions

Q: What’s the difference between 5052-H32 and 5052-H34?

A: H34 has slightly higher strength due to additional cold working.

Q: Can 5052 aluminum be welded?

A: Yes, it welds easily using MIG or TIG methods.

Q: Is 5052 aluminum magnetic?

A: No, like all aluminum alloys, it’s non-magnetic.

Q: What’s the price difference between 5052 and 3003?

A: 5052 typically costs 10-15% more due to magnesium content.

Q: How does 5052 compare to 5083 for marine use?

A: 5083 offers higher strength, but 5052 provides better formability at lower cost.