3003 Aluminum Foil

3003 aluminum foil is a common product of AL-Mn series alloys. Its strength is higher than that of 1 series aluminum foil. At the same time, it has good form-ability, weld-ability and corrosion resistance. It is used for processing parts that require good form-ability, high corrosion resistance and good weld-ability.

| Alloy | 3003 Aluminum Alloy |

| Temper | O, H14, H16, H18, H19, H22, H24, H26, H28 |

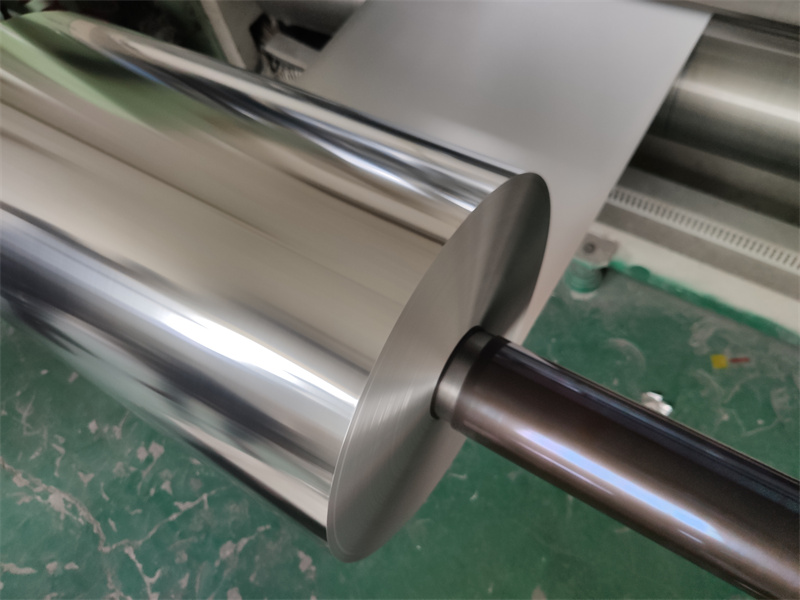

| Surface | Smooth |

| Color | Silver |

| Thickness | 0.014-0.2mm |

| Width | 100-1600mm |

| Length | Coil |

| MOQ | 3 tons |

Application

Generally, 3003 aluminum foil is suitable for application in many fields like building products, chemical and food industries, etc.

- Building products: aluminum honeycomb core, roofing, siding, acoustic ceilings, corrugated sheets.

- Chemical and food industry: storage tanks, pipes, jacketing, container lunch box, food packaging foil.

- Typical use: heat exchangers, air condition evaporators, motor vehicle radiators and freezer linings, etc.

Advantage

- Good weld-ability and form-ability

- Good corrosion resistance

- Anti-rust

- High elongation and tensile strength

- Excellent weather resistance

- Smooth surface

Aluminum 3003

- 3003 Aluminum Alloy

3003 aluminum alloy is an AL-Mn alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high, but slightly higher than that of commercial pure aluminum. The properties cannot be strengthened by heat treatment, and only cold working methods can be used to improve its mechanical properties. Such alloys have high plasticity in the annealed state, and good plasticity in semi-cold work hardening. In addition, it has low plasticity during cold work hardening, good corrosion resistance and good weld-ability. Mainly used for parts with high requirements, plasticity and good weld-ability, such as fuel tanks, gasoline or lubricating oil conduits, various liquid containers and other small load parts made by deep drawing, etc.

2. Chemical Composition

Mn | 1.0-1.5 |

Cu | 0.05-0.2 |

Fe | 0.7 |

Si | 0.60 |

Zn | 0.10 |

Al | Remain |

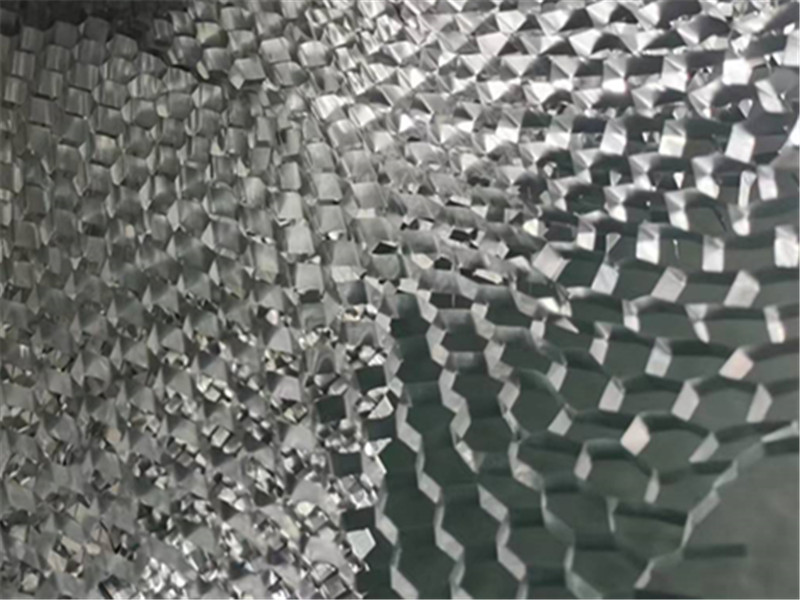

3003 Aluminum Honeycomb Core

The aluminum honeycomb core is made by bonding multiple layers of aluminum foil and then unfolding into a regular honeycomb shape. The factors affecting the performance of honeycomb core materials mainly include parameters such as aluminum foil, node glue and honeycomb core specifications. As an important material, aluminum foil has an impact on the quality of the honeycomb core and its use time.

The aluminum honeycomb core is a hexagonal honeycomb core made of 3003 aluminum foil, and the thickness of the aluminum foil is 0.02~0.06mm.

3003-h18 aluminum foil is used as the aluminum foil base material for honeycomb core. And its strength is much higher than that of 1100 aluminum foil. The finished product is not easy to be deformed, flat end face, the edge has no burr, and high flatness .

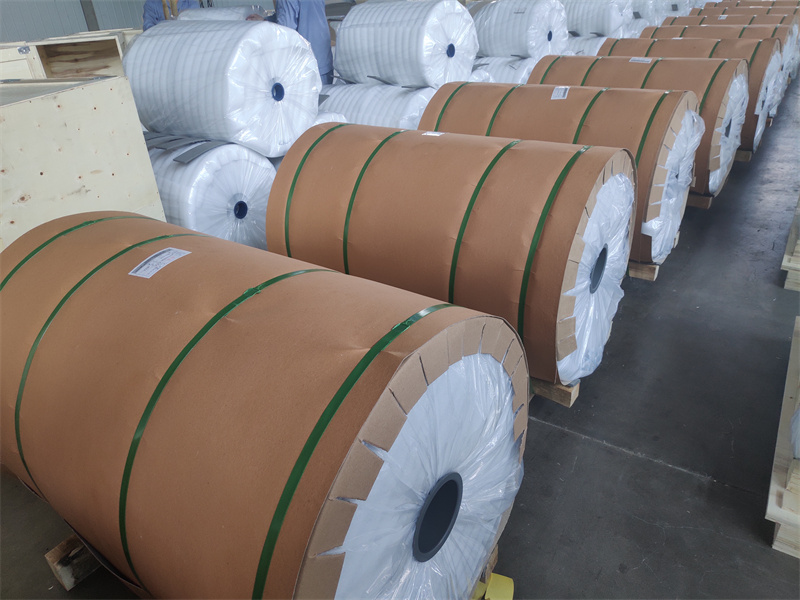

Packaging

Aluminum Foil Factory

WORTHWILL is professional in aluminum foil products. Some products include household foil, pharmaceutic foil, container foil, packaging foil, electronic foil. Our factory has built up more than ten years. And it’s one of the most excellent aluminum manufacturer in the middle of Henan, China. It’s also verified and a gold member of made-in-China with different aluminum sheets, coils and foil various from 1000 series to 8000 series. We provide customized services include size, thickness and packaging. If you are interested in our products, welcome to contact us.

What is 3003 aluminum foil?

3003 aluminium foil is a common product of 300 series alloys, and it has excellent corrosion resistance, weldability and corrosion resistance, so it is widely used in house facades, decoration materials, plates, decoration packaging, building hardware and other fields.